Plant efficient drip irrigation fertilizer

A drip irrigation fertilizer and high-efficiency technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve problems such as poor plant growth, nutrient imbalance, and increased production costs, and achieve easy plant absorption, comprehensive nutrition, and promote vegetable growth. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

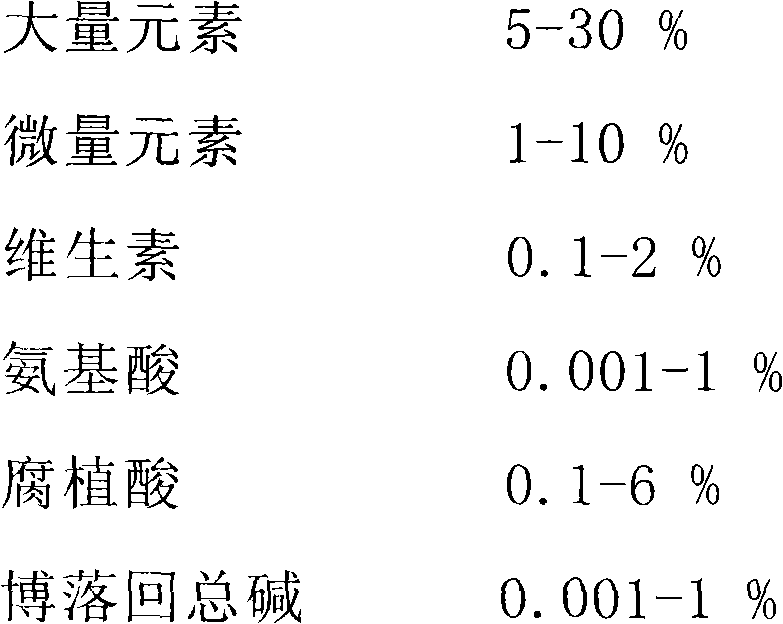

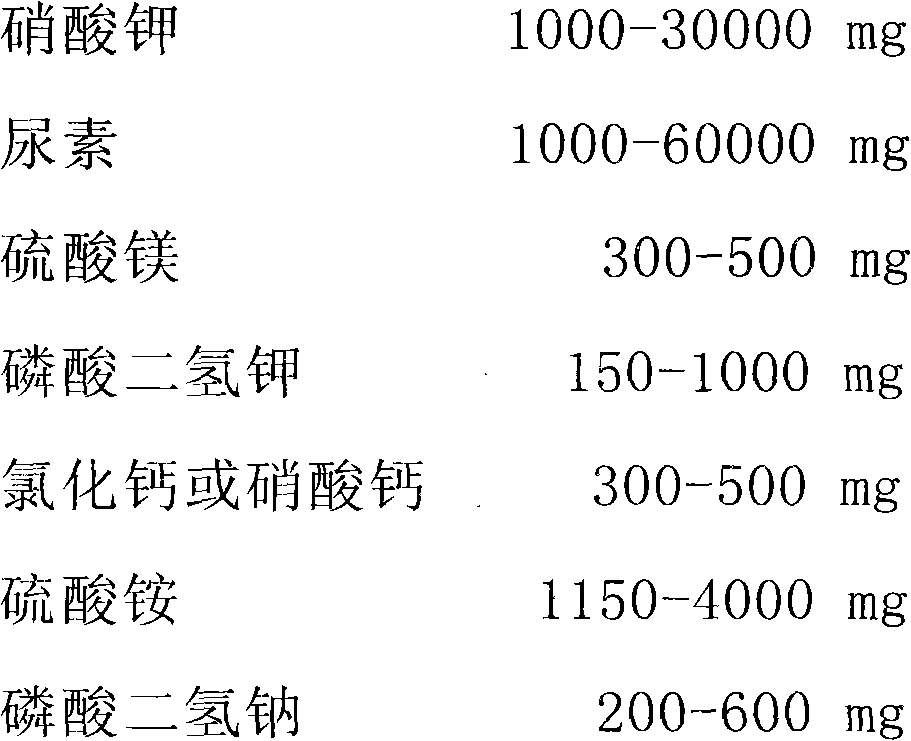

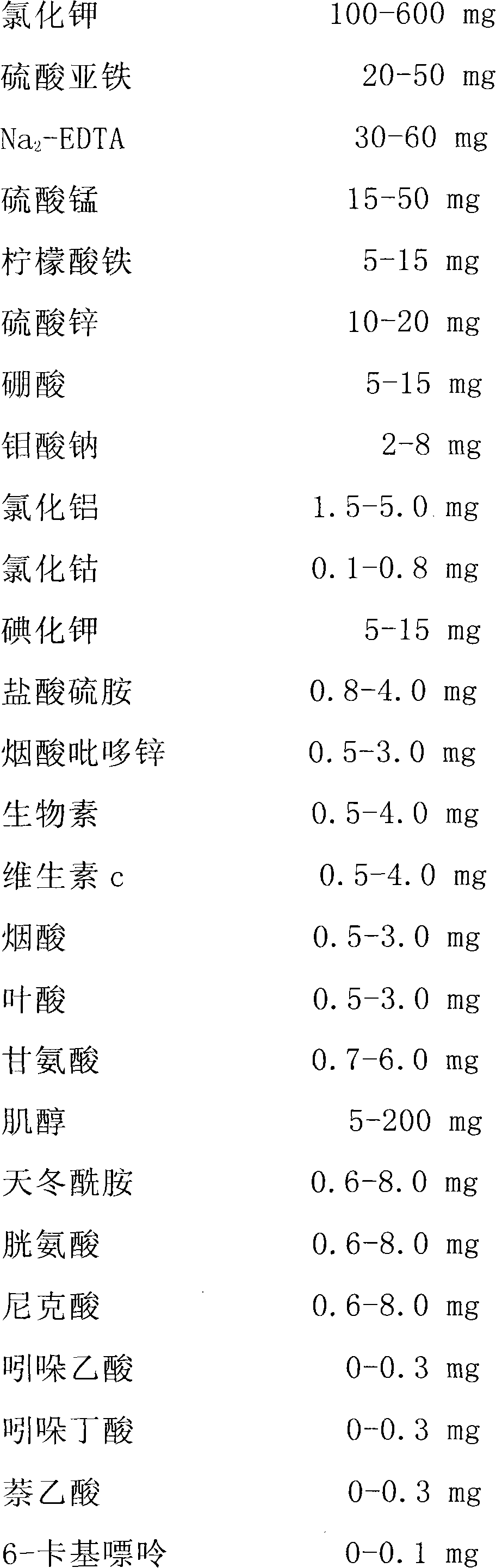

Method used

Image

Examples

Embodiment 1

[0030] The quality ratio is as follows: potassium nitrate 1000mg, urea 1000mg, magnesium sulfate 300mg, potassium dihydrogen phosphate 150mg, calcium chloride 300mg, ferrous sulfate 20mg, Na 2 -EDTA30mg; iron citrate 5mg, manganese sulfate 15mg, zinc sulfate 10mg, boric acid 5mg, niacin 0.5mg; glycine 0.7mg, inositol 5mg, aspartic acid 0.6mg; sanguinarine 1mg, chelidonine 1mg ; Humic acid 1000mg, after mixing well, dilute to 1000ml with deionized water.

[0031] After the nutrient solution is diluted 500 times, it is sprayed on the lettuce grown for one month. After 10 days, the leaves were dark green and thick, showing a significant yield increase effect.

Embodiment 2

[0033] The following mass substances: potassium nitrate 30000mg, urea 60000mg, magnesium sulfate 500mg, potassium dihydrogen phosphate 1000mg, calcium nitrate 500mg, ferrous sulfate 50mg, Na2-EDTA 60mg; iron citrate 15mg, manganese sulfate 50mg, zinc sulfate 20mg, boric acid 15mg, niacin 3mg; glycine 6mg, inositol 200mg, aspartic acid 8mg; sanguinarine 100mg, chelidonine 100mg; humic acid 50000, after mixing thoroughly, dilute the volume to 1000ml with deionized water.

[0034] After the nutrient solution is diluted 500 times, it is sprayed on tomatoes that have grown for one month. After 10 days, the leaves were dark green and thick, showing a significant yield increase effect.

Embodiment 3

[0036] The quality ratio is as follows: potassium nitrate 10000mg, urea 30000mg, magnesium sulfate 400mg, potassium dihydrogen phosphate 600mg, calcium chloride 200mg, calcium nitrate 200mg, ferrous sulfate 40mg, Na 2 -EDTA50mg; iron citrate 10mg, manganese sulfate 35mg, zinc sulfate 15mg, boric acid 10mg, niacin 1.9mg; glycine 4mg, inositol 100mg, aspartic acid 3.5mg; sanguinarine 50mg, chelidonine 50mg; Humic acid 500mg, after mixing well, dilute to 1000ml with deionized water.

[0037] After the nutrient solution is diluted 500 times, it is sprayed on tomatoes that have grown for one month. After 10 days, the leaves were dark green and thick, showing a significant yield increase effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com