Method for preparing zoledronic acid and sodium salt thereof by utilizing phase transfer catalyst

A technology of phase transfer catalyst and zoledronic acid, which is applied in the direction of chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve the problem of poor yield of product zoledronic acid High, gradual thickening, unsatisfactory, etc., to achieve good industrial application prospects, increased yield, and good product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

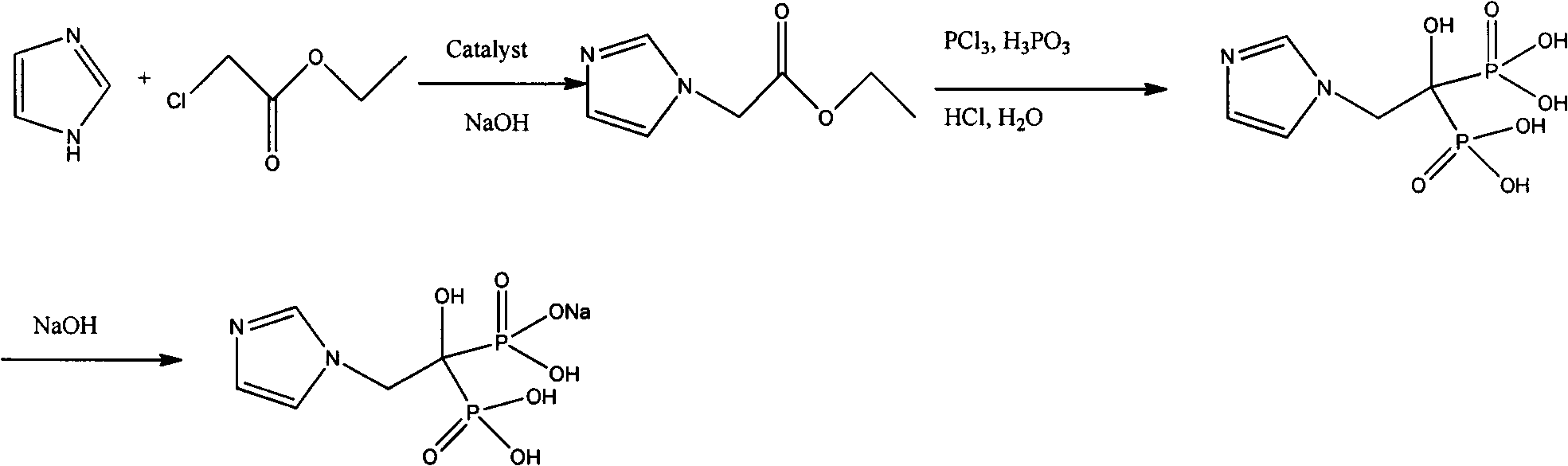

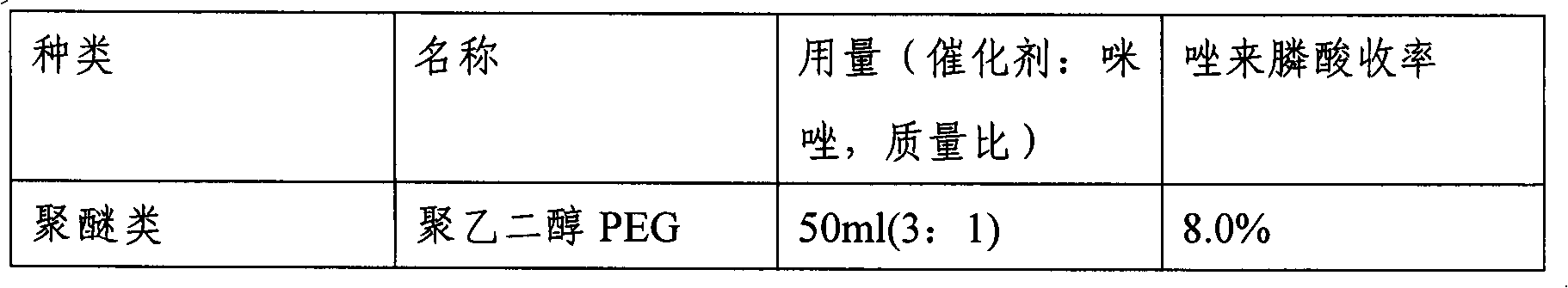

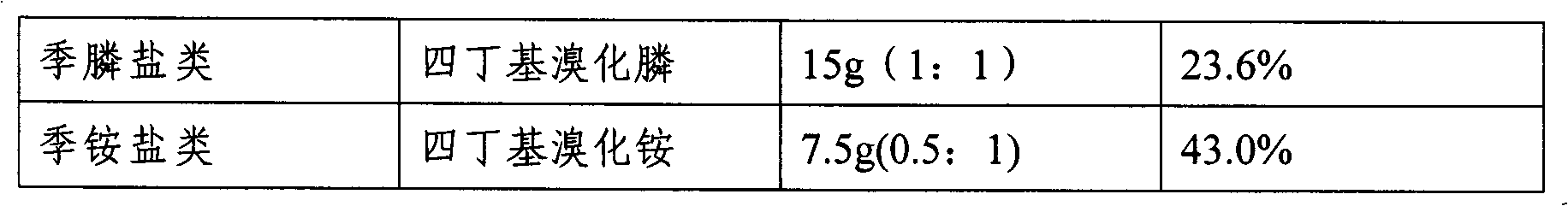

Method used

Image

Examples

Embodiment 1

[0025] Add 15g of imidazole and 200ml of 1,4-dioxane into a 500ml three-necked flask, stir at room temperature to dissolve. Add 10g of sodium hydroxide and 3g of benzyltriethylammonium chloride (phase transfer catalyst TEBA), stir evenly, then add about 40ml of excess ethyl chloroacetate dropwise, and the dropwise addition is completed after 0.5h. TLC showed the degree of progress of the reaction (the developer was ethyl acetate:petroleum ether=5:1, 10% phosphomolybdic acid was used as the developer), and the reaction was complete after 2 hours.

[0026] At room temperature, after adding 36g of phosphorous acid and stirring to dissolve, slowly add 38ml of excess phosphorus trichloride dropwise, and the dropwise addition is completed after 1 hour. After 4 hours, TLC showed that the reaction was complete, and the reaction was allowed to stand at room temperature overnight.

[0027] Turn on mechanical stirring, slowly add 70ml of distilled water dropwise (to neutralize excess ph...

Embodiment 2

[0031] Add 15g of imidazole and 200ml of tetrahydrofuran into a 500ml three-necked flask, stir at room temperature to dissolve. Add 9.7g of sodium hydroxide and 2.3g of benzyltriethylammonium chloride (phase transfer catalyst TEBA), stir well, then add about 35ml of excess ethyl chloroacetate dropwise, and dropwise complete after 0.5h. TLC showed the degree of progress of the reaction (the developer was ethyl acetate:petroleum ether=5:1, 10% phosphomolybdic acid was used as the developer), and the reaction was complete after 2 hours.

[0032] At room temperature, after adding 36.5g of phosphorous acid and stirring to dissolve, slowly add 40ml of excess phosphorus trichloride dropwise, and the dropwise addition is completed after 1.5h. After 4 hours, TLC showed that the reaction was complete, and the reaction was allowed to stand at room temperature overnight.

[0033] Turn on mechanical stirring, slowly add 100ml of distilled water dropwise (to neutralize excess phosphorus tr...

Embodiment 3

[0036] Add 15g of imidazole and 200ml of 1,4-dioxane into a 500ml three-necked flask, stir at room temperature to dissolve. Add 10.5g of sodium hydroxide and 4.5g of benzyltriethylammonium chloride (phase transfer catalyst TEBA), stir evenly, then add about 45ml of excess ethyl chloroacetate dropwise, and the dropwise addition is completed after 0.8h. TLC showed the degree of progress of the reaction (the developer was ethyl acetate:petroleum ether=5:1, 10% phosphomolybdic acid was used as the developer), and the reaction was complete after 2 hours.

[0037] At room temperature, after adding 40 g of phosphorous acid and stirring to dissolve, slowly add 38 ml of excess phosphorus trichloride dropwise, and the dropwise addition is completed after 1 hour. After 4 hours, TLC showed that the reaction was complete, and the reaction was allowed to stand at room temperature overnight.

[0038]Turn on mechanical stirring, slowly add 70ml of distilled water dropwise (to neutralize exce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com