Method for producing diosmin

A production method and technology of diosmin, applied in chemical instruments and methods, sugar derivatives, sugar derivatives, etc., can solve the problems of operation risk, large volatilization loss, and high equipment requirements, and achieve low production cost and high yield. High rate and content, stable process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following production process should determine the cleanliness level of each area according to GMP specifications. The clean area is class 100,000.

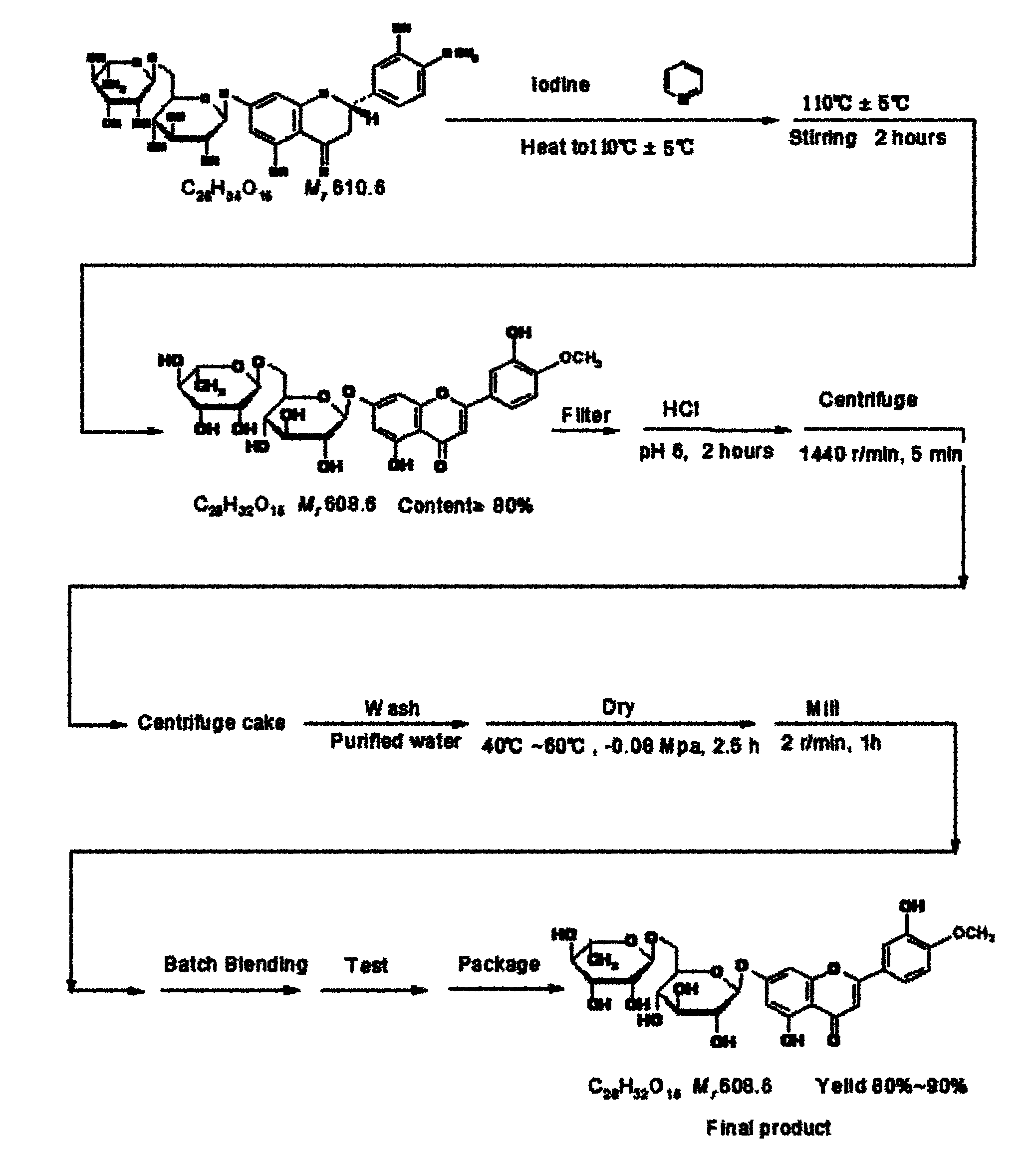

[0025] First, the main reaction: put 360 kilograms of hesperidin, 42 kilograms of iodine and 1474 kilograms of pyridine (1500L) into the reaction kettle in sequence, close the kettle mouth, stir, slowly heat to reflux, stir and heat to a temperature of 110 ° C ± 5 under normal pressure ℃, keep the temperature at 110℃±5℃ and stir the reaction for 2 hours, then take a sample and detect it by HPLC detection method, stop the reaction when the concentration of hesperidin is less than 5% of diosmin, heat and recover the solvent pyridine;

[0026] Second, cleaning: Add 1 ton of pure water to the concentrated paste, add 79.5 kg of soda ash, stir for one hour, put the evenly stirred material into an open stainless steel mixing tank, add 150 kg of hydrochloric acid, and adjust the pH value to 7 , filter the material with a filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com