Method for safely extracting cordyceps sinensis polysaccharide

A technology of Cordyceps polysaccharides and extraction methods, which can be applied to anti-toxins, digestive system, metabolic diseases, etc., can solve food safety hazards and other problems, and achieve good effect, convenient operation, and improved purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

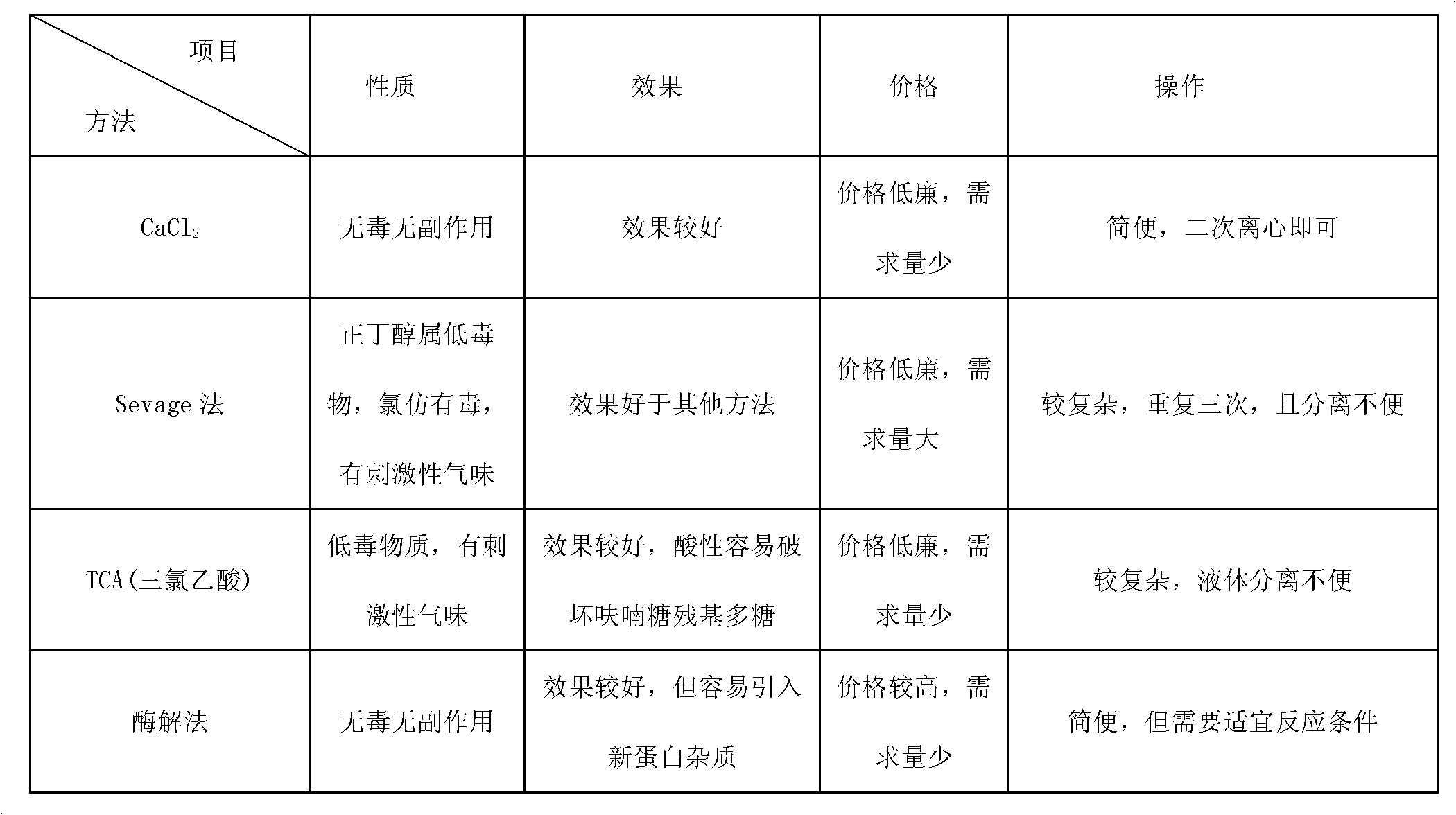

Method used

Image

Examples

Embodiment 1

[0020] (1) Extraction: the Cordyceps sinensis sporocarps dried at 60°C are pulverized with a traditional Chinese medicine pulverizer and passed through a 40-mesh sieve, weighed 10 grams of powder, added 100ml of distilled water, extracted at a water temperature of 60°C for 8 hours, centrifuged (3000r / min, 10 minutes) to collect the supernatant, extract the precipitate with distilled water, repeat the extraction three times, and combine to obtain the extract.

[0021] (2) Concentration: Add the extract to the evaporating flask of the rotary evaporator, the vacuum degree is: -0.1MPa, adjust the temperature of the water bath to 60°C, concentrate the extract to one-third of the original volume, and obtain the concentrated of the extract.

[0022] (3) Deproteinization: Add calcium chloride to the concentrated extract to make the concentration 3% (w / v), adjust the pH to 4, shake at room temperature for 30 minutes and then centrifuge to remove the protein precipitate, and then Calc...

Embodiment 2

[0027] (1) Extraction: the Cordyceps sinensis sporocarp that was dried at 60°C was pulverized with a traditional Chinese medicine pulverizer and passed through a 60-mesh sieve, and 10 grams of powder was weighed, added to 200ml of distilled water, extracted at a water temperature of 60°C for 8 hours, and centrifuged (3000r / min , 10 minutes) to collect the supernatant, extract the precipitate with distilled water, repeat the extraction three times, and combine the extracts.

[0028] (2) Concentration: Add the extract to the evaporating flask of the rotary evaporator, the vacuum degree is: -0.1MPa, adjust the temperature of the water bath to 60°C, concentrate the extract to one-third of the original volume, and obtain the concentrated of the extract.

[0029] (3) Deproteinization: Add calcium chloride to the concentrated extract, the mass volume ratio of the added calcium chloride to the extract is 40:1g / L, adjust the pH to 5, shake at room temperature for 60 minutes Centrifuge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com