Nonlinear optical crystal material Sr3Y3BiB4O15 and preparation method and application thereof

A technique of nonlinear optics, crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] SrCO in molar ratio 3 :Y 2 o 3 : Bi 2 o 3 :H 3 BO 3 =6:3:1:8 Weigh the following reagents:

[0045] SrCO 3 : 8.8578 g, Y 2 o 3 : 6.7743 g, Bi 2 o 3 : 4.6596 g, H 3 BO 3 : 4.9464 grams.

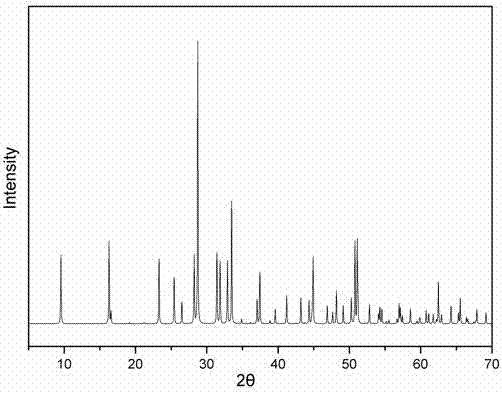

[0046] Grind the weighed reagent evenly in an agate grinding machine, then transfer it to a Pt crucible, put it into a muffle furnace, and sinter it at 500°C for 4 hours, take it out and cool it, grind it well, then put it into the muffle furnace, the temperature Sinter at 800°C for 10 hours, take it out and cool it down and grind it thoroughly, then put it into the muffle furnace, raise the temperature to 900°C for sintering for 24 hours, take it out and cool it, grind it well, then put it in the muffle furnace, at 900°C After sintering for 24 hours, Sr 3 Y 3 BiB 4 o 15 Polycrystalline powder samples.

Embodiment 2

[0048] SrCO in molar ratio 3 :Y 2 o 3 : Bi 2 o 3 :H 3 BO 3 =6:3:1:8 Weigh the following reagents:

[0049] SrCO 3 : 2.2145 g, Y 2 o 3 : 1.6936 g, Bi 2 o 3 : 1.1649 g, H 3 BO 3 : 1.237 g.

[0050] Put the weighed reagent in a clean beaker, add a certain amount of 1mol / L nitric acid solution, heat and stir on a magnetic stirrer, dissolve into a transparent solution, add a certain amount of citric acid, and wait until it dissolves into a transparent solution. Heat slowly on an electric stove and gradually evaporate the water. Then the solid content in the beaker was transferred to a Pt crucible, placed in a muffle furnace to burn at 800°C, and then sintered at 900°C for 24 hours. High-purity Sr can be obtained 3 Y 3 BiB 4 o 15 Polycrystalline powder samples.

Embodiment 3

[0053] SrCO in molar ratio 3 : Y 2 o 3 : Nd 2 o 3 : Bi 2 o 3 :H 3 BO 3 =6:3:(1- x ): x : 8 (0 x <0.5) Weigh the following reagents:

[0054] SrCO 3 : 2.2145 g, Y 2 o 3 : 1.5807 g, Nd 2 o 3 : 0.1683 g ( x =0.0005mol), Bi 2 o 3 : 1.1649 g, H 3 BO 3 : 1.237 g.

[0055] Grind the weighed reagent evenly in an agate grinding machine, then transfer it to a Pt crucible, put it into a muffle furnace, and sinter it at 500°C for 4 hours, take it out and cool it, grind it well, then put it into the muffle furnace, the temperature Sinter at 800°C for 10 hours, take it out and cool it down and grind it thoroughly, then put it into the muffle furnace, raise the temperature to 900°C for sintering for 24 hours, take it out and cool it, grind it well, then put it in the muffle furnace, at 900°C Then sinter for 24 hours to get Nd 3+ :Sr 3 Y 3 BiB 4 o 15 Polycrystalline powder samples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com