Circular-waveguide slow-wave structure for angularly loading spiral line

A slow-wave structure and helical technology, applied in the field of traveling wave tube amplifier devices, can solve the problems of reduced power and gain of the whole tube, unfavorable equipment miniaturization, and large device operating voltage, so as to reduce the phase velocity and improve the interaction efficiency. , the effect of low operating voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

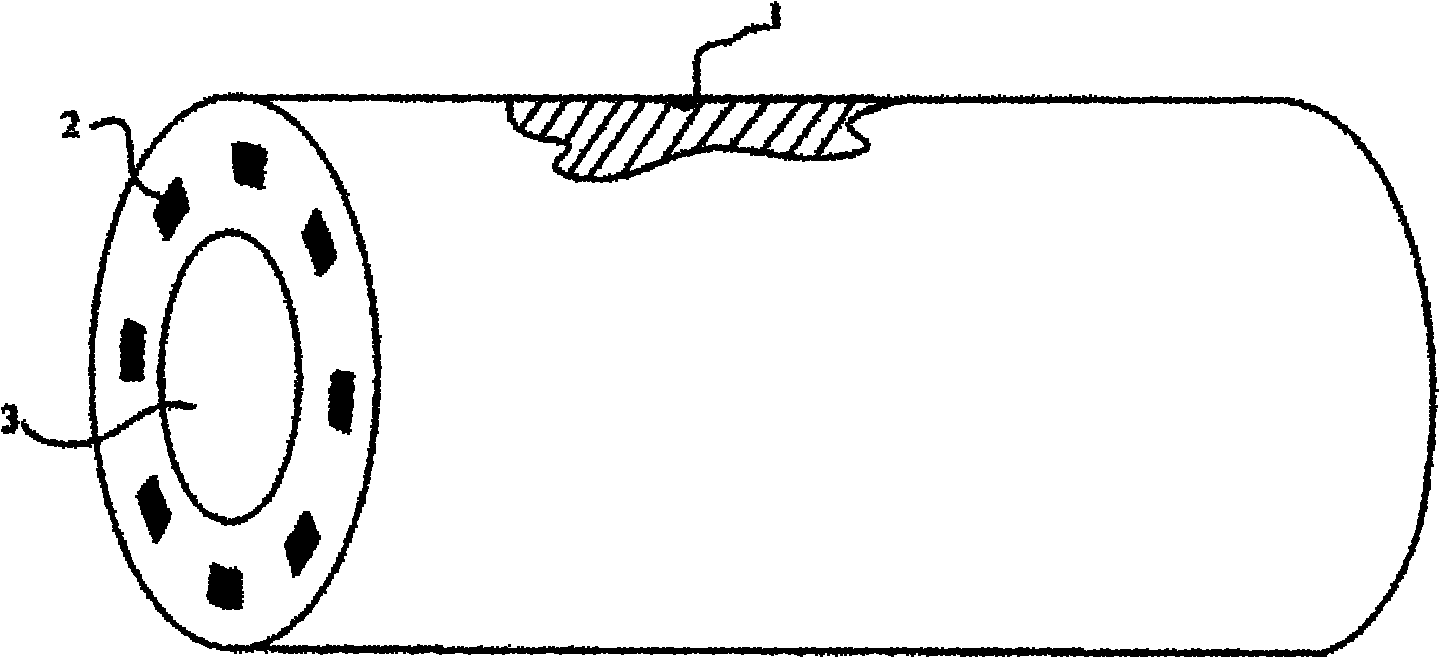

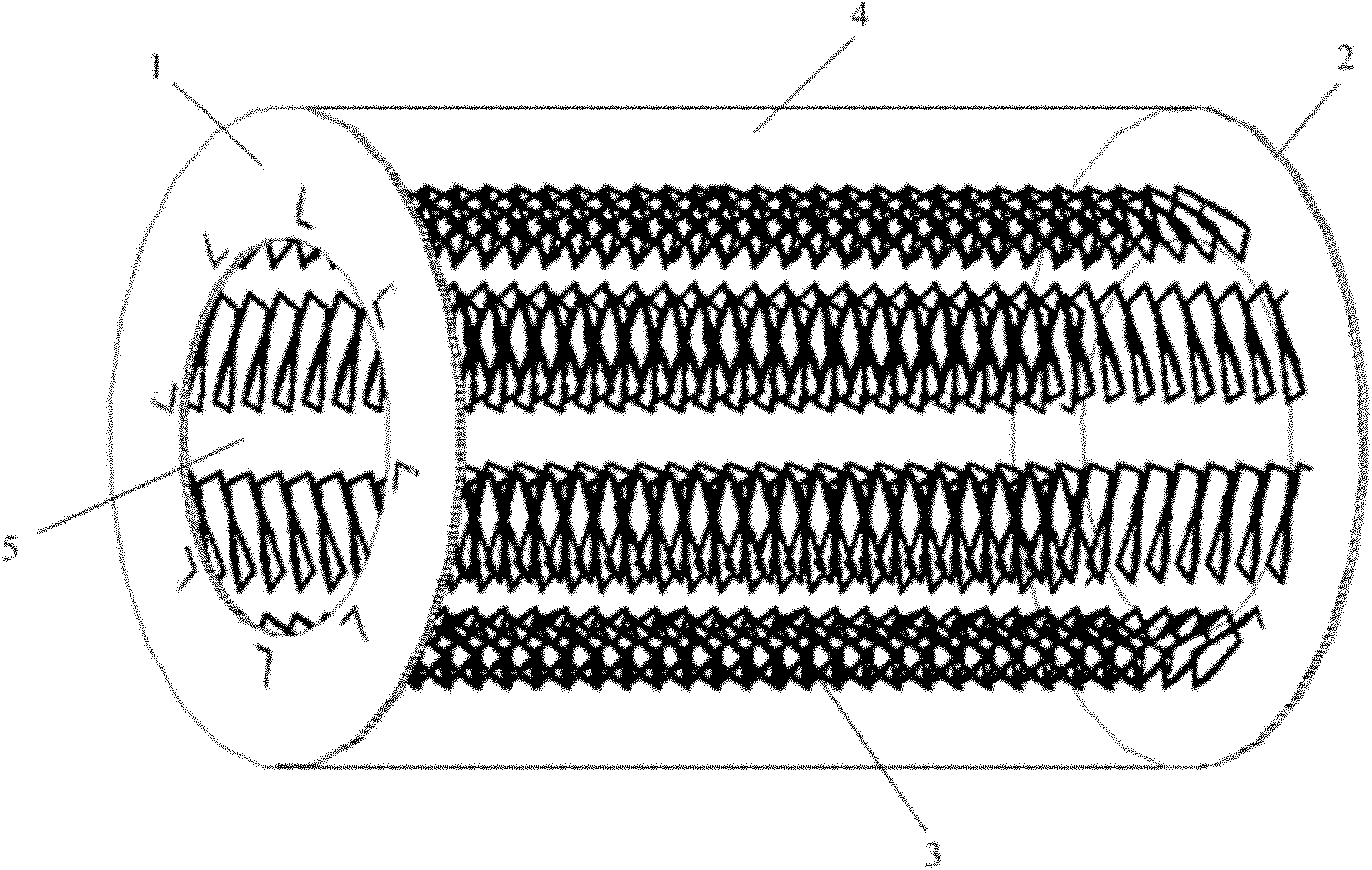

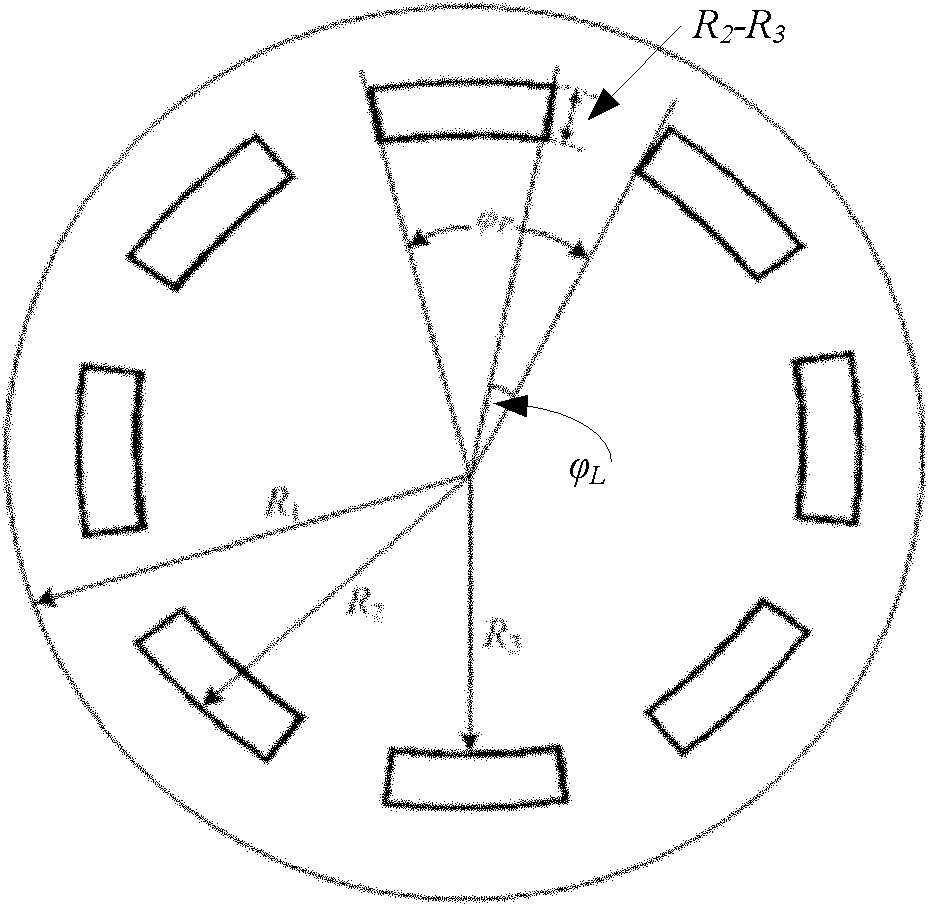

[0017] A circular waveguide slow-wave structure with an angularly loaded helix, such as figure 2 shown, including a radius R 1 A circular waveguide 4, N identical helixes 3 and two outer radii R 1 , the inner radius is R 5 The ring dielectric sheets 1 and 2; two ring dielectric sheets 1 and 2 are respectively fixed on the two end faces of the circular waveguide 4, and N identical helixes 3 are connected between the two ring dielectric sheets 1 and 2 , so that N identical helixes 3 are angularly evenly distributed inside the circular waveguide 4 . More specifically, N identical helixes 3 are angularly evenly distributed in the circular waveguide 4 with an outer diameter R 2 , the inner diameter is R 3 In the circular cylindrical space of , the angular distance between two adjacent helixes 3 is 2π / N, and R 1 2 3 5 ; The hollow parts of the two annular dielectric sheets and the space parts surrounded by all the helixes jointly form the electron injection channel 5 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com