Lincomycin wastewater advanced treatment and water recycling technology

An advanced treatment, lincomycin technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve high operating costs and low treatment efficiency To solve problems such as large investment in equipment, etc., to achieve broad application prospects, ideal treatment effect, and water saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

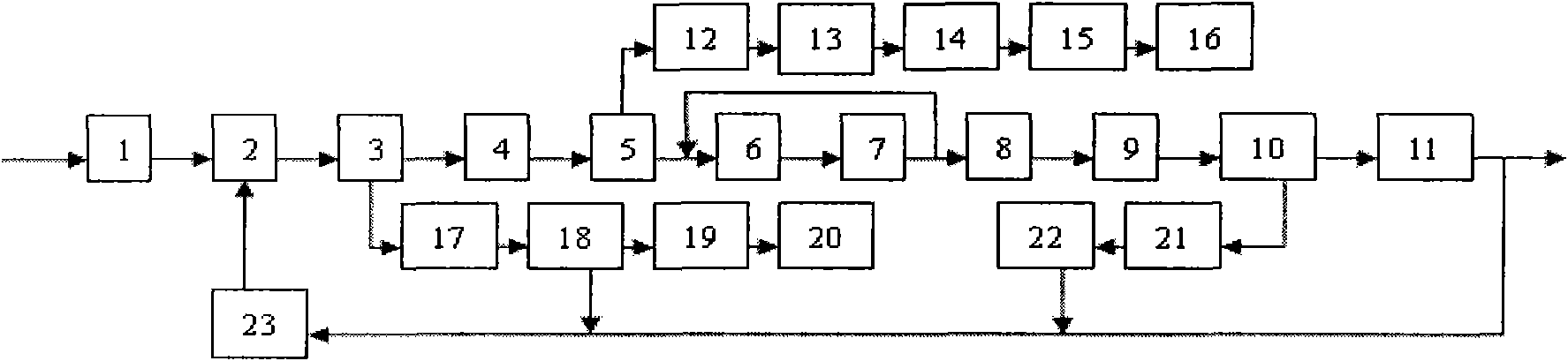

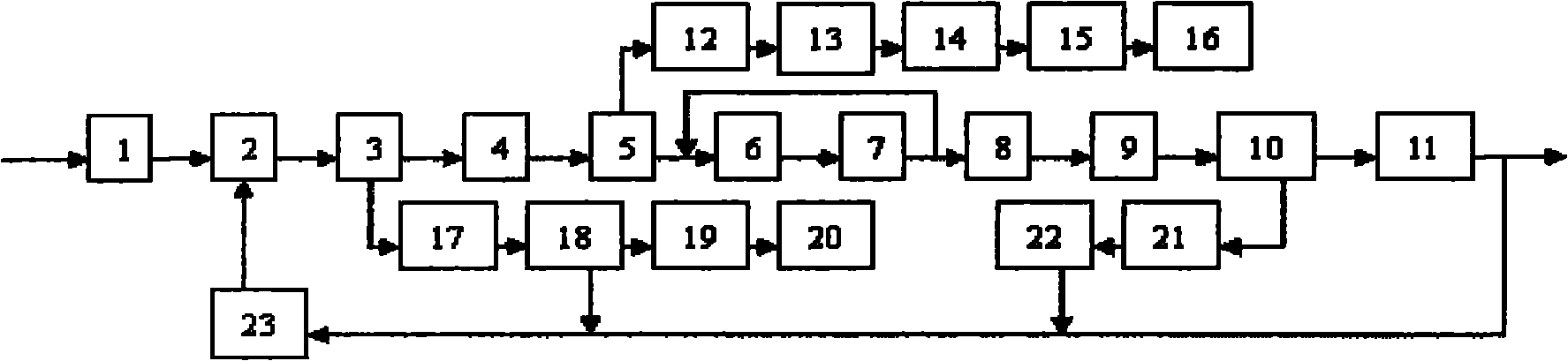

[0038] A process for advanced treatment of lincomycin wastewater and reuse of reclaimed water, which includes the following steps: the lincomycin wastewater produced in the production process of lincomycin passes through a grid 1, a water collection tank 2, and a primary sedimentation tank 3 , regulating tank 4, IC reactor 5, anoxic tank 6, aerobic tank 7 to secondary sedimentation tank 8 biochemical treatment of lincomycin wastewater biochemical effluent obtained, its COD value reaches 608mg / L, and then through the filter 9 1. Activated carbon adsorption bed 10 is adsorbed, and its flow rate is controlled to be 7.5BV / h, and it is ensured that every 100L of secondary precipitation effluent is adsorbed by 1kg of activated carbon bed, and when the effluent flows into the storage tank 11, its COD average value reaches 19mg / L, and the effluent Without color, it can be drained or reused in reclaimed water.

[0039] The regenerated waste liquid is neutralized by the regenerated liqu...

Embodiment 2

[0041] A process for advanced treatment of lincomycin wastewater and reuse of reclaimed water, which includes the following steps: the lincomycin wastewater produced in the production process of lincomycin passes through a grid 1, a water collection tank 2, and a primary sedimentation tank 3 , regulating tank 4, IC reactor 5, anoxic tank 6, aerobic tank 7 to secondary sedimentation tank 8 biochemical treatment of lincomycin wastewater biochemical effluent obtained, its COD value reaches 468mg / L, and then through the filter 9 1. Activated carbon adsorption bed 10 is adsorbed, and its flow rate is controlled as 5BV / h, and it is ensured that every 100L of secondary precipitation effluent is adsorbed by 1kg of activated carbon bed, and when the effluent flows into the storage tank 11, its COD average value reaches 14mg / L, and the effluent has no color, it can be discharged or reused as reclaimed water.

[0042] The regenerated waste liquid is neutralized by the regenerated liquid ...

Embodiment 3

[0044] A process for advanced treatment of lincomycin wastewater and reuse of reclaimed water, which includes the following steps: the lincomycin wastewater produced in the production process of lincomycin passes through a grid 1, a water collection tank 2, and a primary sedimentation tank 3 , regulating tank 4, IC reactor 5, anoxic tank 6, aerobic tank 7 to secondary sedimentation tank 8 biochemical treatment of lincomycin wastewater biochemical effluent obtained, its COD value reaches 730mg / L, and then through the filter 9 1. Activated carbon adsorption bed 10 is adsorbed, and its flow rate is controlled at 7BV / h to ensure that every 100L of secondary precipitation effluent is adsorbed by 1kg of activated carbon bed, and when the effluent flows into the storage tank 11, the average value of COD reaches 27mg / L, and the effluent has no color , which can be discharged or reused as reclaimed water.

[0045] The regenerated waste liquid is neutralized by the regenerated liquid an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com