Method for preparing Ag/PMMA (polymethyl methacrylate) nano composite material

A technology of nanocomposite materials and nanosol, which is applied in the field of preparation of Ag/PMMA nanocomposite materials, can solve the problems of not using Ag/PMMA nanocomposite materials, and achieve the prevention of aging and etching, controllable design and preparation, The effect of uniform and stable distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

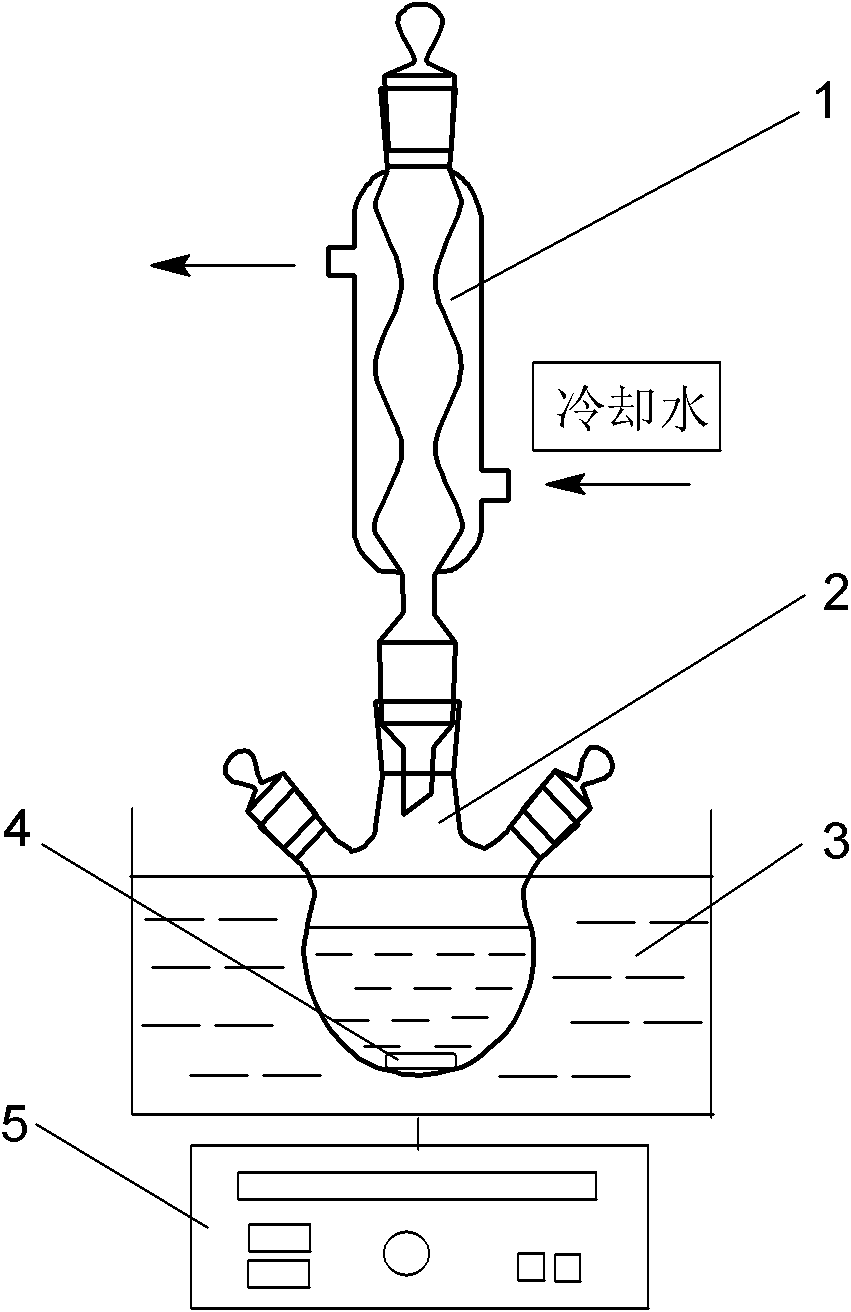

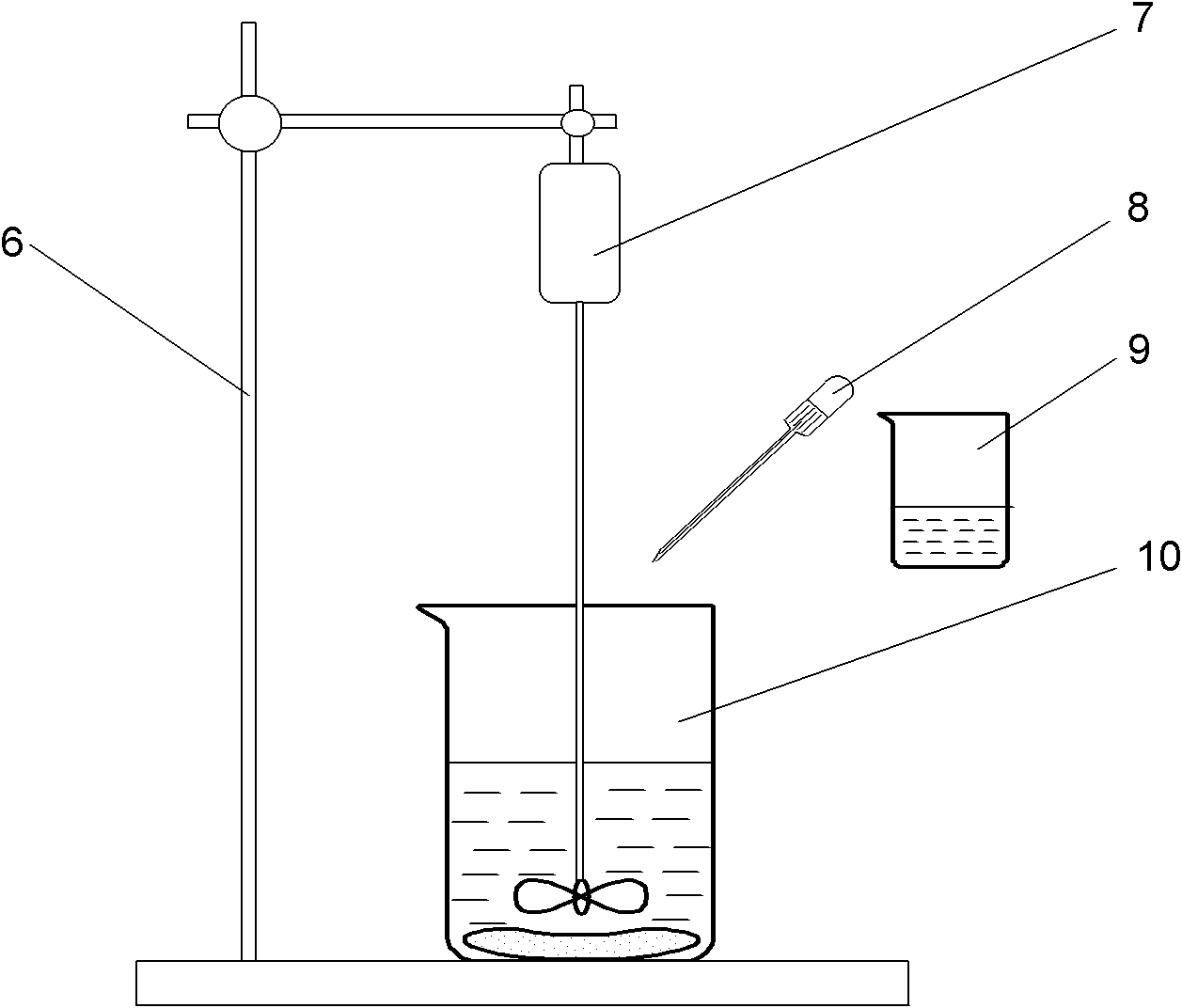

Method used

Image

Examples

specific example 1

[0036] 1. Put 7.5g PMMA (average molecular weight 300,000) and 140g DMF into the reaction vessel, add 0.04g PVP (average molecular weight 40,000) and stir for 30min to mix evenly, then add 0.0612g AgNO 3 , after heating and reacting at 140° C. for 5 min, stop heating to obtain Ag / PMMA sol containing Ag nanoparticles.

[0037] 2. Under the condition of strong mechanical stirring, slowly pour the Ag / PMMA nano-sol into the ethanol solvent for solvent precipitation, and wash the precipitate with fresh ethanol 3 times after filtration, wherein the volume ratio of the Ag / PMMA nano-sol to the ethanol solvent is 1:10 .

[0038]3. The Ag / PMMA precipitate was dried at 60°C for one week, and then hot-pressed at 180°C to obtain the Ag / PMMA nanocomposite material.

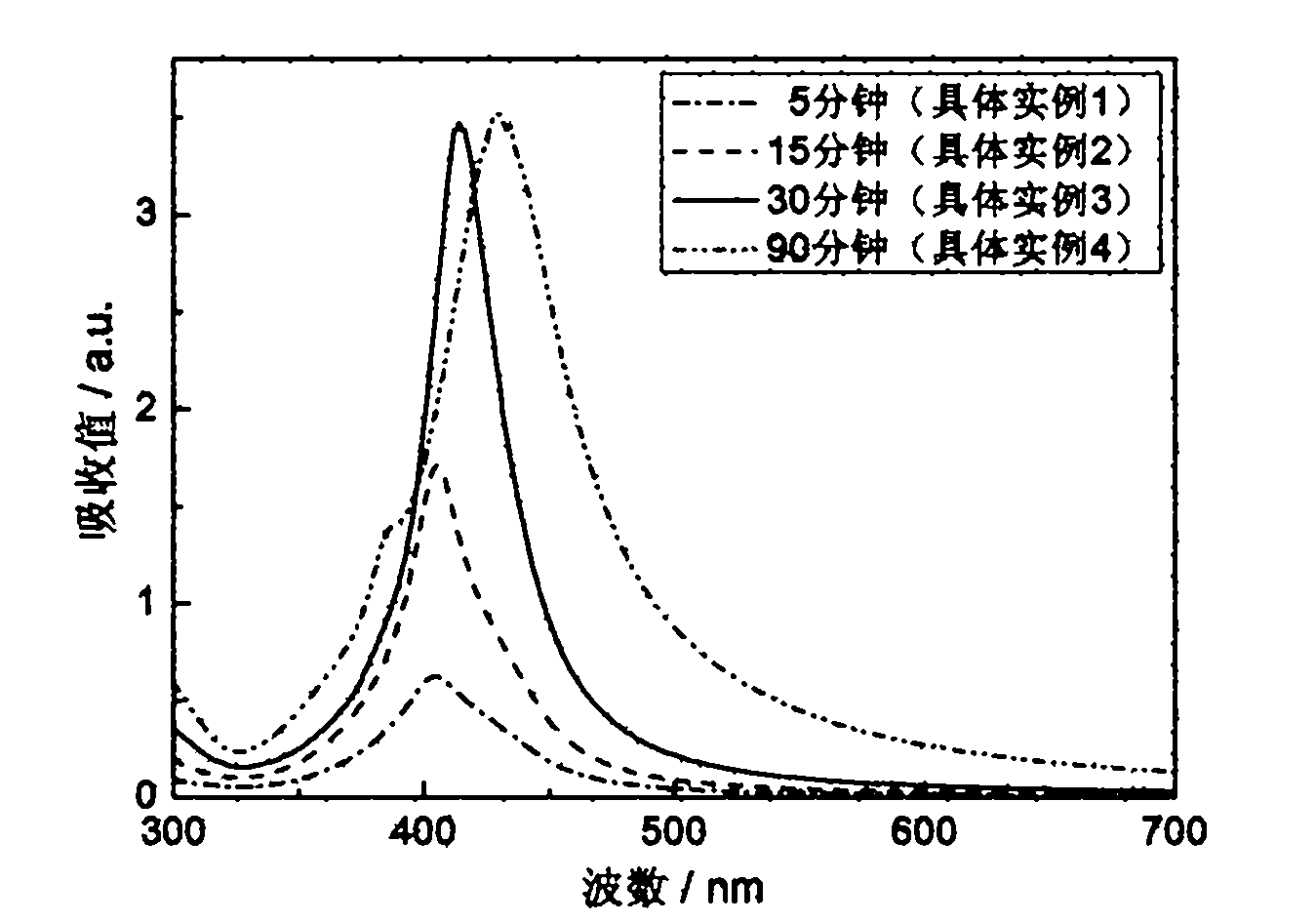

[0039] The content of Ag nanoparticles in the Ag / PMMA sol that this method obtains is 0.5wt.%, and its ultraviolet visible spectrogram is as follows image 3 As shown, the absorption peak in the wavenumber range of 400-450nm ...

specific example 2

[0041] 1. Put 7.5g PMMA (average molecular weight 300,000) and 140g DMF into the reaction vessel, add 0.04g PVP (average molecular weight 40,000) and stir for 30min to mix evenly, then add 0.0612g AgNO 3 , after heating and reacting at 140° C. for 15 min, the heating was stopped to obtain Ag / PMMA sol containing Ag nanoparticles.

[0042] 2. Under the condition of strong mechanical stirring, slowly pour the Ag / PMMA nano-sol into the ethanol solvent for solvent precipitation, and wash the precipitate with fresh ethanol 3 times after filtration, wherein the volume ratio of the Ag / PMMA nano-sol to the ethanol solvent is 1:10 .

[0043] 3. The Ag / PMMA precipitate was dried at 60°C for one week, and then hot-pressed at 180°C to obtain the Ag / PMMA nanocomposite material.

[0044] The content of Ag nanoparticles in the Ag / PMMA sol that this method obtains is 0.5wt.%, and its ultraviolet visible spectrogram is as follows image 3 As shown, the absorption peak in the wavenumber range ...

specific example 3

[0046] 1. Put 7.5g PMMA (average molecular weight 300,000) and 140g DMF into the reaction vessel, add 0.04g PVP (average molecular weight 40,000) and stir for 30min to mix evenly, then add 0.0612g AgNO 3 , after heating and reacting at 140° C. for 30 min, stop heating to obtain Ag / PMMA sol containing Ag nanoparticles.

[0047] 2. Under the condition of strong mechanical stirring, slowly pour the Ag / PMMA nano-sol into the ethanol solvent for solvent precipitation, and wash the precipitate with fresh ethanol 3 times after filtration, wherein the volume ratio of the Ag / PMMA nano-sol to the ethanol solvent is 1:10 .

[0048] 3. The Ag / PMMA precipitate was dried at 60°C for one week, and then hot-pressed at 180°C to obtain the Ag / PMMA nanocomposite material.

[0049] The content of Ag nanoparticles in the Ag / PMMA sol that this method obtains is 0.5wt.%, and its ultraviolet visible spectrogram is as follows image 3 As shown, the absorption peak in the wavenumber range of 400-450n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com