Ti-Ni-Hf-Cu quaternary high-temperature shape memory alloy film and preparation method thereof

A technology of ti-ni-hf-cu, 1.ti-ni-hf-cu, applied in the field of thin film and its preparation, can solve the problem of low phase transition temperature and achieve the effect of cost reduction and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0011] Embodiment 1: In this embodiment, the Ti-Ni-Hf-Cu quaternary high-temperature shape memory alloy thin film is composed of four elements: Ti, Ni, Hf and C, wherein the atomic number ratio of Ni is 34-49%, Hf The atomic number ratio of Cu is 10-25%, the atomic number ratio of Cu is 1-15%, and the rest is Ti, and the sum of the number of Ti atoms and the number of Hf atoms is equal to the ratio of the number of Ni atoms and the number of Cu atoms And the ratio of 1.041 ~ 1.222:1.

specific Embodiment approach 2

[0012] Specific embodiment two: the preparation method of the Ti-Ni-Hf-Cu quaternary high-temperature shape memory alloy film in this embodiment is as follows: 1. Put the substrate on the target stage of the vacuum chamber, and use Ti-Ni-Hf-Cu four Elemental alloy target as the target material,

[0013] Then sputtering under the conditions of sputtering power 100W~600W, vacuum degree 0.1Pa~0.8Pa, distance between target material and substrate is 4cm~9cm, to obtain thin film; The crystallization is completed by heat preservation for 30-60 minutes under the condition of ℃, and the Ti-Ni-Hf-Cu quaternary high-temperature shape memory alloy film is obtained; the number of atoms of Ni in the Ti-Ni-Hf-Cu quaternary alloy target described in step The number ratio is 34-49%, the atomic number ratio of Hf is 10-25%, the atomic number ratio of Cu is 1-15%, and the rest is Ti, and the sum of the number of Ti atoms and the number of Hf atoms is equal to that of Ni The ratio of the number...

specific Embodiment approach 3

[0017] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the substrate in step 1 is Si single wafer, quartz glass, copper foil or aluminum sheet. Others are the same as in the second embodiment.

[0018] The Si single wafer described in this embodiment is a p-Si (100) polished single wafer.

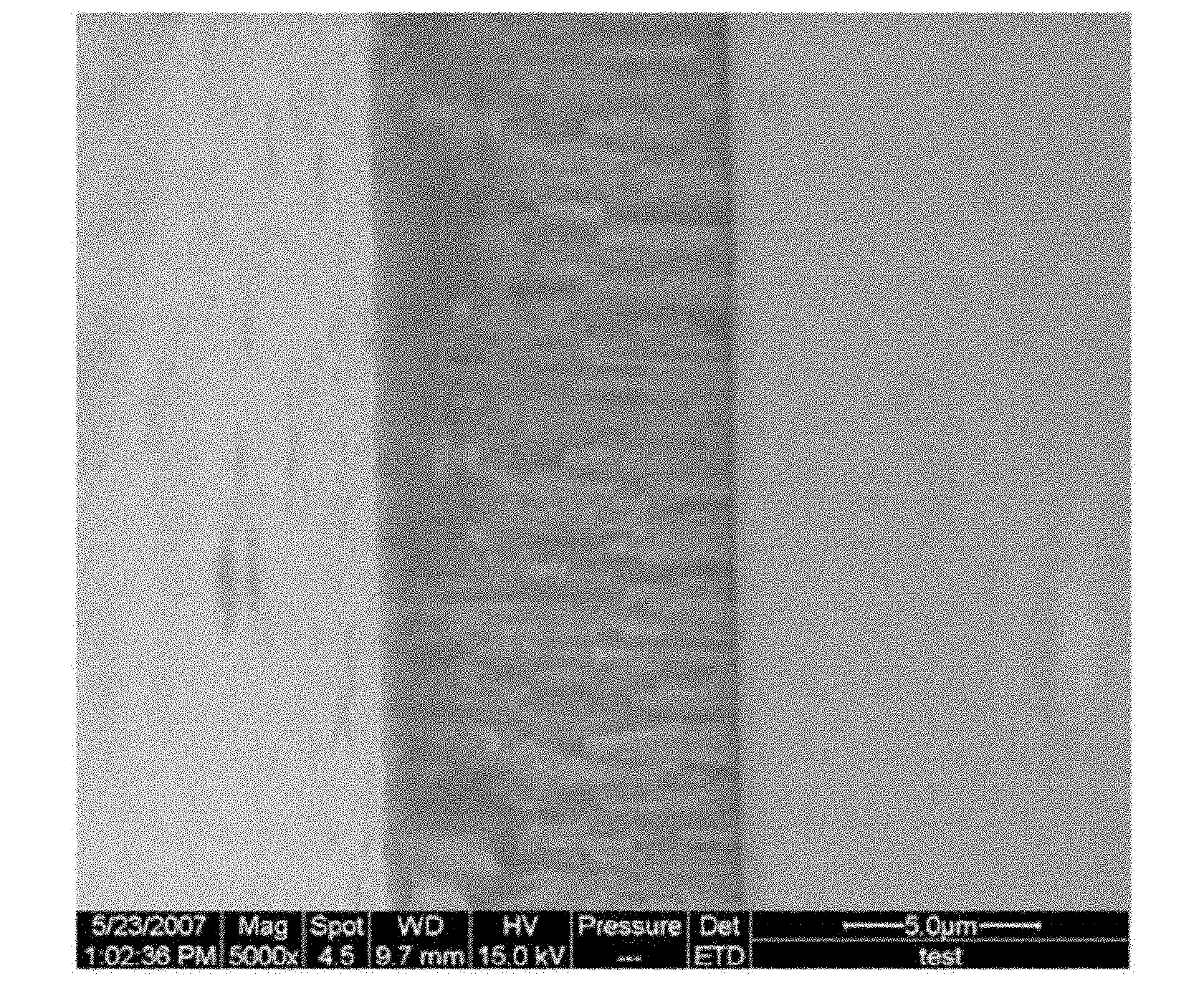

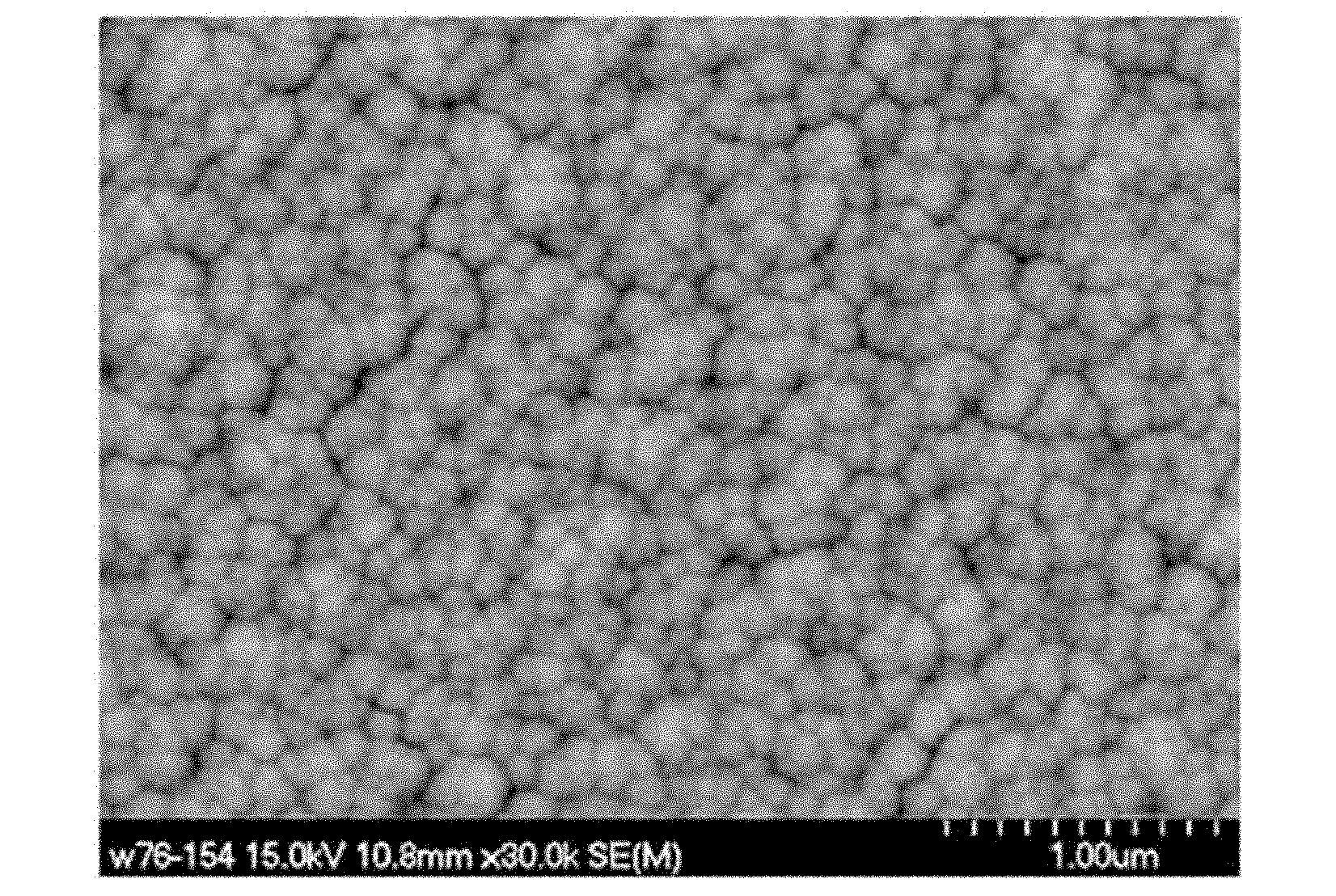

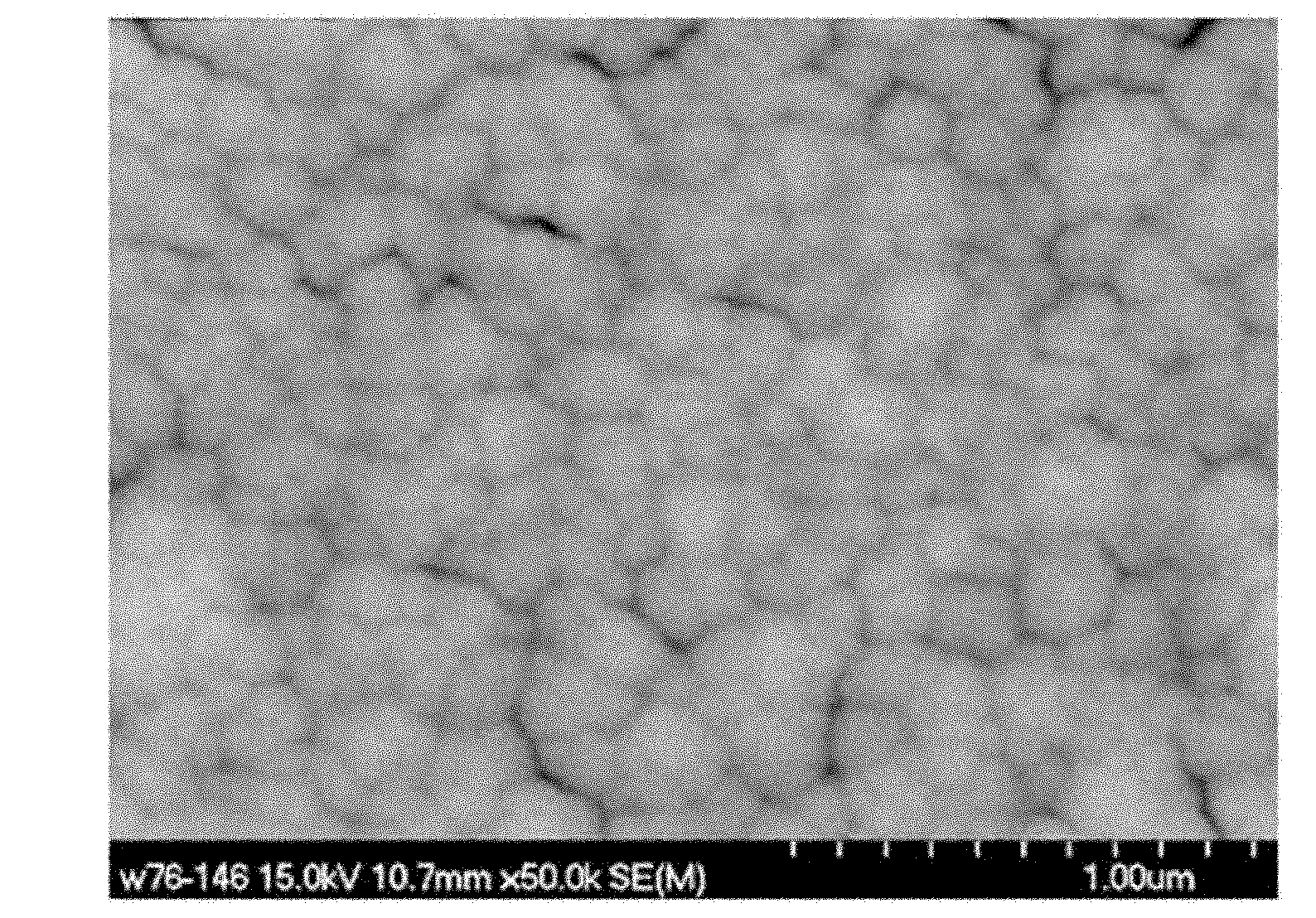

[0019] In the thin film preparation process, both the type of substrate and the cleanliness of the surface have an important impact on the quality of the thin film. For Si substrates, due to the particularity of the Si manufacturing process, impurities such as metal K ions and Na ions will remain on the Si surface, and impurities such as oxygen atoms will also be adsorbed. As a result, the deposited atoms nucleate first at the impurities, making the The point atoms are dense, holes may appear on the surface of the film or cause the surface of the film to be uneven, and the unclean substrate is likely to cause low adhesion between the film and the substrate, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com