Method for improving appearance of phosphosilicate glass by virtue of high-density plasma chemical vapor deposition (HDP CVD)

A technology of chemical vapor deposition and phospho-silicate glass, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of SAC etching rate decrease, contact holes cannot be etched through, and increase bombardment intensity, etc., to achieve weakening Secondary sputtering, beneficial to self-aligned contact hole etching, and the effect of reducing width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

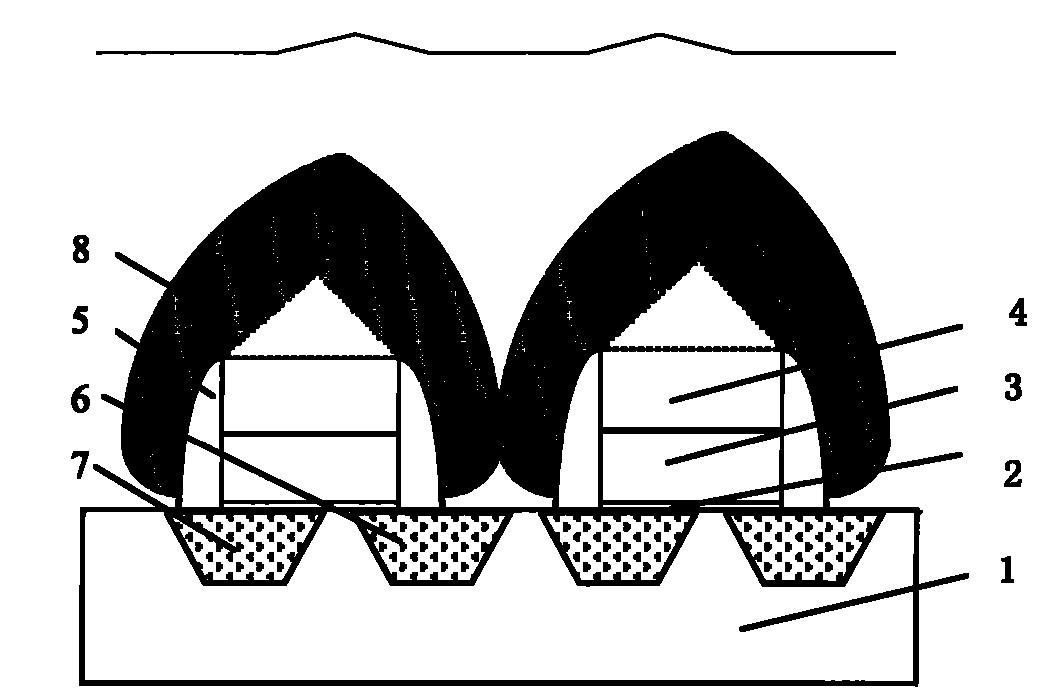

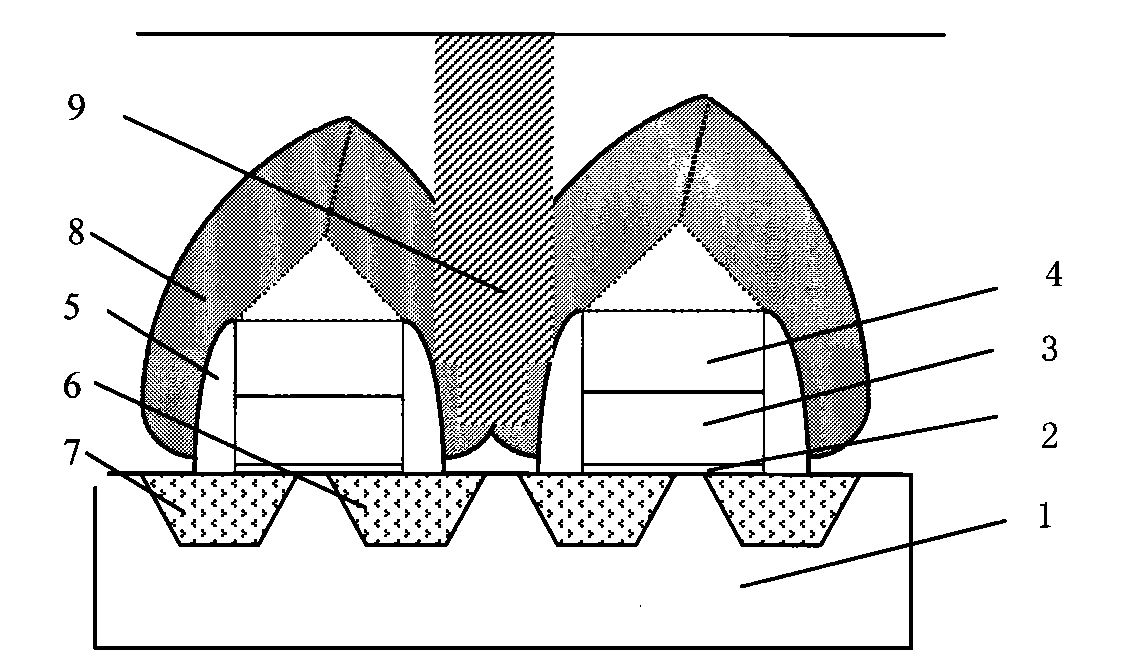

[0027] Such as Figure 3-Figure 7 As shown in the present invention, a high-density plasma chemical vapor deposition phosphosilicate glass morphology method specifically includes the following steps:

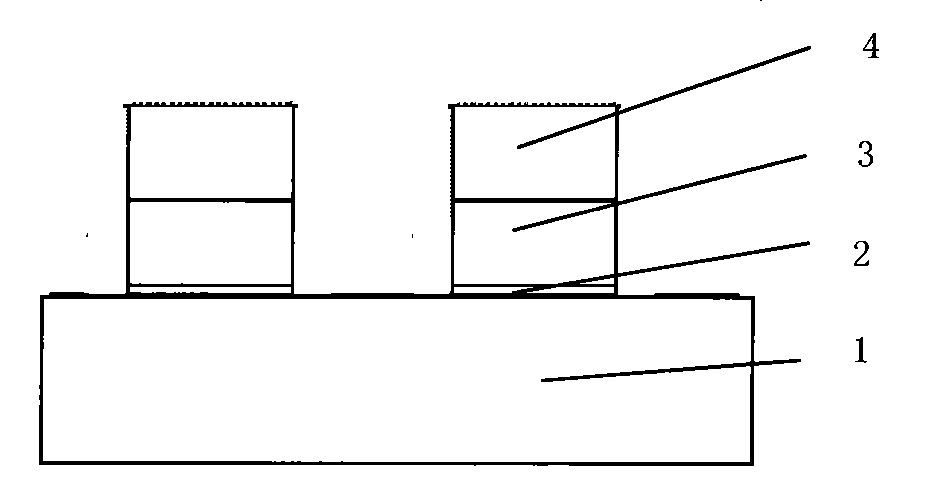

[0028] The first step is to form a gate electrode on the silicon substrate 1, using a conventional process method, generally first depositing a gate oxide layer 2 on the silicon substrate 1, then depositing a polysilicon layer 3 on the gate oxide layer 2, and then Depositing a silicon nitride layer 4 on the polysilicon layer 3, polysilicon photolithography and etching, forming a polysilicon gate electrode, see image 3 ;

[0029] In the second step, LDD (Light Doped Drain, lightly doped source and drain regions) is implanted, and then sidewalls 5 are formed on the sidewalls of the gate electrode. The sidewalls 5 are formed by using a conventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com