Method of manufacturing organic el display unit and organic el display unit

A display unit, an organic technology, applied in semiconductor/solid-state device manufacturing, electrical components, devices for coating liquid on the surface, etc., can solve high equipment manufacturing costs, difficult separation and coating of metal masks, and large screens that cannot be applied Substrate and other issues to achieve the effect of improving luminous efficiency and life, and improving the interface state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

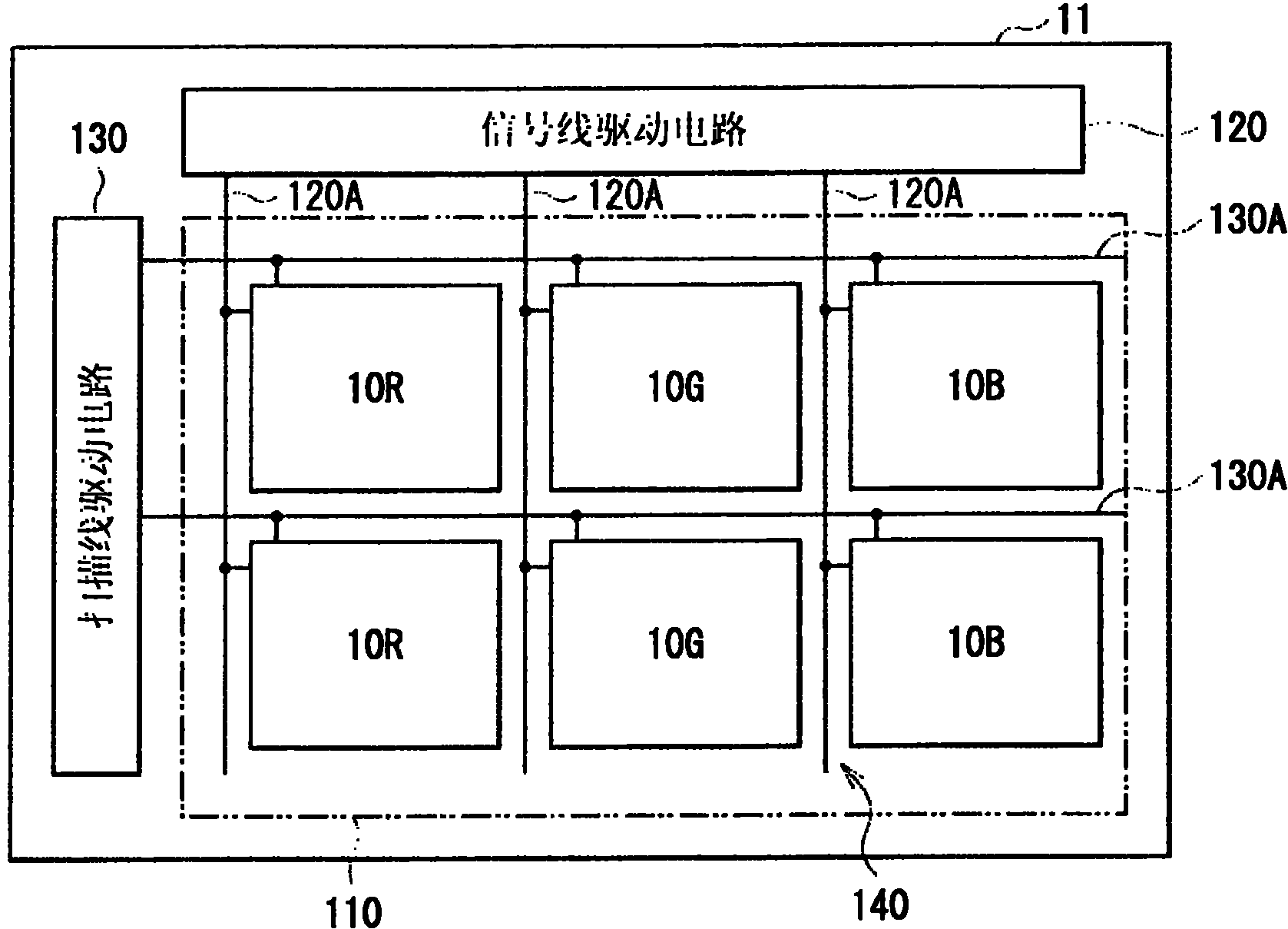

[0163] The substrates 11 were formed to have a size of 25 mm×25 mm for the red organic EL device 10R, the green organic EL device 10G, and the blue organic EL device 10B, respectively.

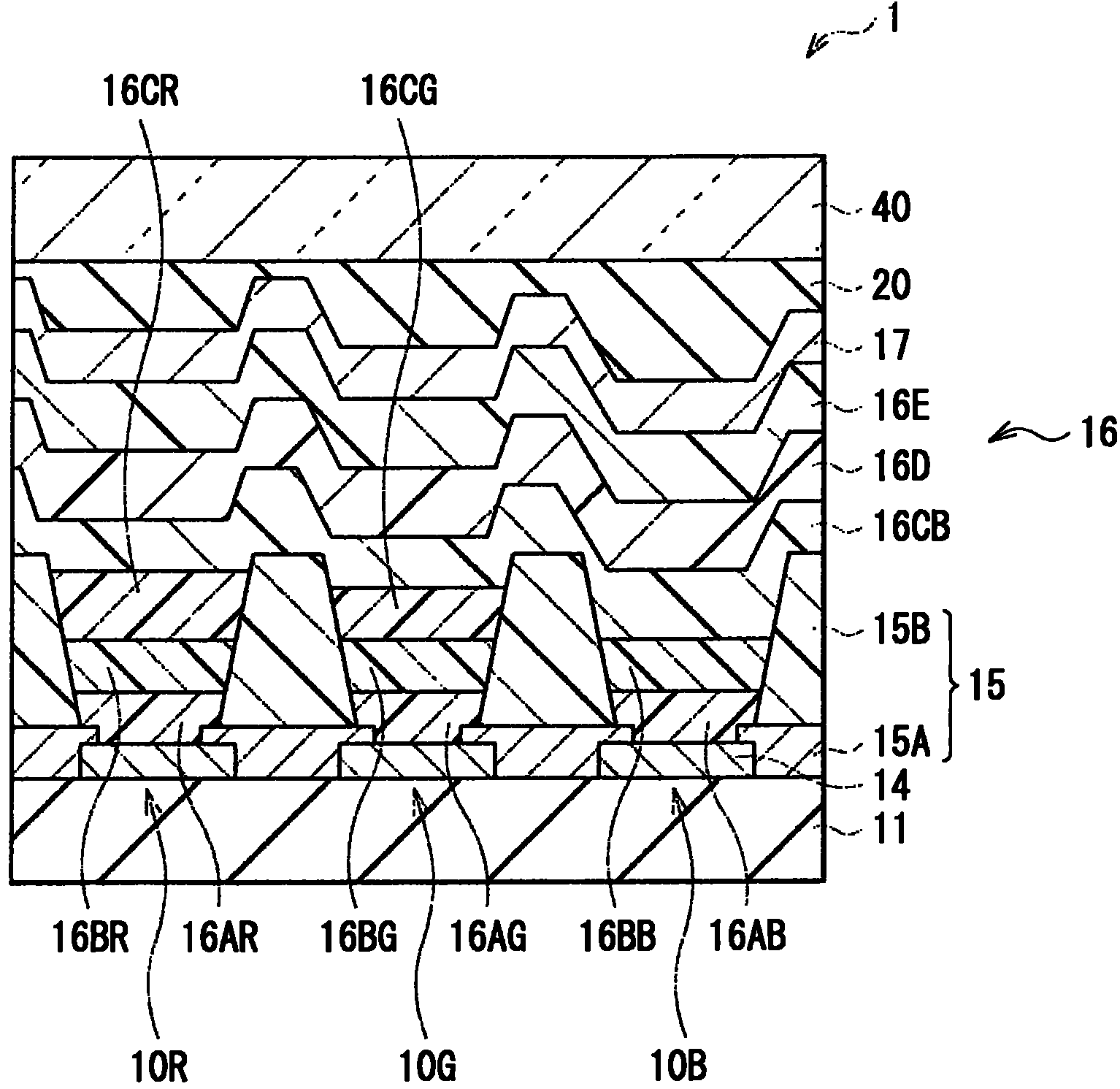

[0164] First, a glass substrate (25 mm×25 mm) was prepared as the substrate 11 . On the substrate 11, a two-layer structure consisting of a silver alloy layer made of Ag-Pd-Cu alloy with a thickness of 120 nm and a transparent conductive film made of ITO with a thickness of 10 nm was formed as the lower electrode 14 (step S101).

[0165]Subsequently, as the hole injection layers 16AR, 16AG, and 16AB, ND 1501 (polyaniline, manufactured by Nissan Chemical Industries Ltd) was coated in air by a spin coating method to have a thickness of 15 nm, and was applied on a hot plate at 220 degrees Celsius. The resulting product is thermally cured for 30 minutes (step S104).

[0166] Thereafter, at N 2 (dew point: -60 degrees Celsius, oxygen concentration: 10 ppm) as a hole transport layer by coating the...

example 2

[0195] An organic EL display unit was fabricated in the same manner as in Example 1, except that in the step of forming the hole transport layer 16BB of the blue organic EL device 10B described in Example 1, the structural formula 1 (58 ).

[0196] Chemical formula 16

[0197] Compound 1(58)

[0198]

example 3

[0200] An organic EL display unit was fabricated in the same manner as in Example 1, except that in the step of forming the hole transport layer 16BB of the blue organic EL device 10B described in Example 1, the structural formula 1 (22 ).

[0201] Chemical formula 17

[0202] Structural formula 1(22)

[0203]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com