Connection method for adjacent meshes of copper alloy trapezius net

A connection method and technology of copper alloy, applied in the directions of wire mesh, textile and paper making, and end bundling, etc., can solve the damage of metal rhombus mesh and connecting wire, the problem of popularization and use of metal rhombus mesh, and restrict the possibility of fishery engineering. Sustainable development and other issues, to achieve the effect of saving breeding costs, reasonable and reliable operation methods, and saving processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Below take the two pieces of copper alloy orthorhombic nets of the mesh foot length 25mm as an example, and illustrate the best mode of the present invention in conjunction with the accompanying drawings:

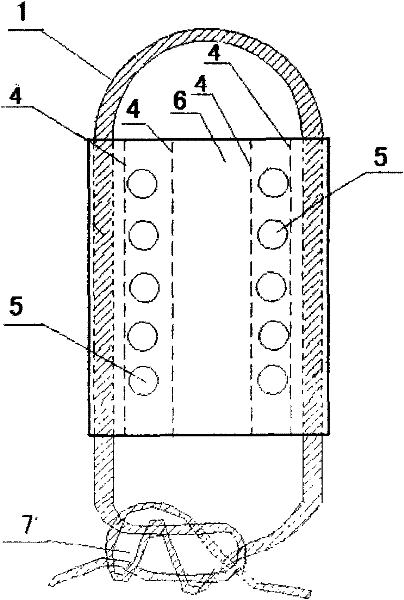

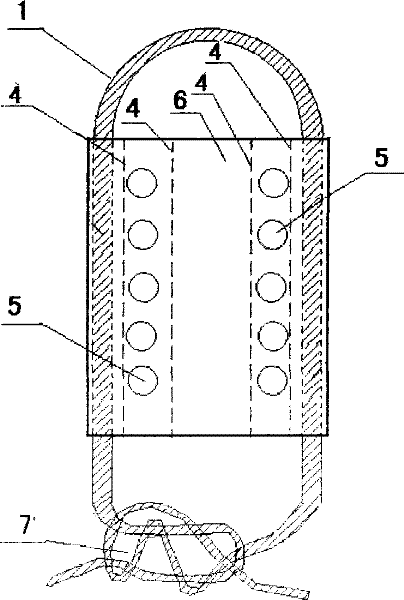

[0009] figure 1 1 in represents the rope used for making soft connectors; figure 1 The 4 in represents the suture thread for making soft connectors; figure 1 5 in represents the eye ring on the soft connector; figure 1 6 in represents the cylindrical webbing used for making soft connectors; figure 1 The 7 in the figure represents the double dead knot made by the two rope ends of the soft connector.

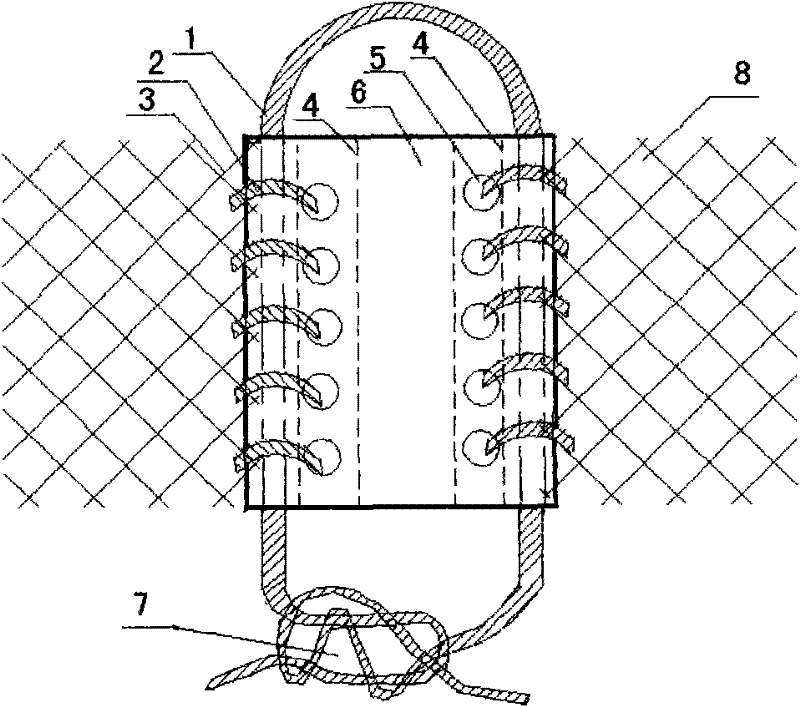

[0010] figure 2 1 in represents the rope used for making soft connectors; figure 2 The 2 in it represents the rope used to connect the copper alloy trapezoidal net and the soft connector; figure 2 3 in represents a piece of copper alloy orthorhombic mesh that needs to be connected; figure 2 The 4 in represents the suture thread for making soft connectors; fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com