Gas washing and recovering device for preparing macromonomers of poly carboxylic acid water reducing agent

A technology of polycarboxylic acid system and recovery device, which is applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., to achieve the effects of increasing contact time, ensuring quality, and scientifically reasonable overall design structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with specific embodiments.

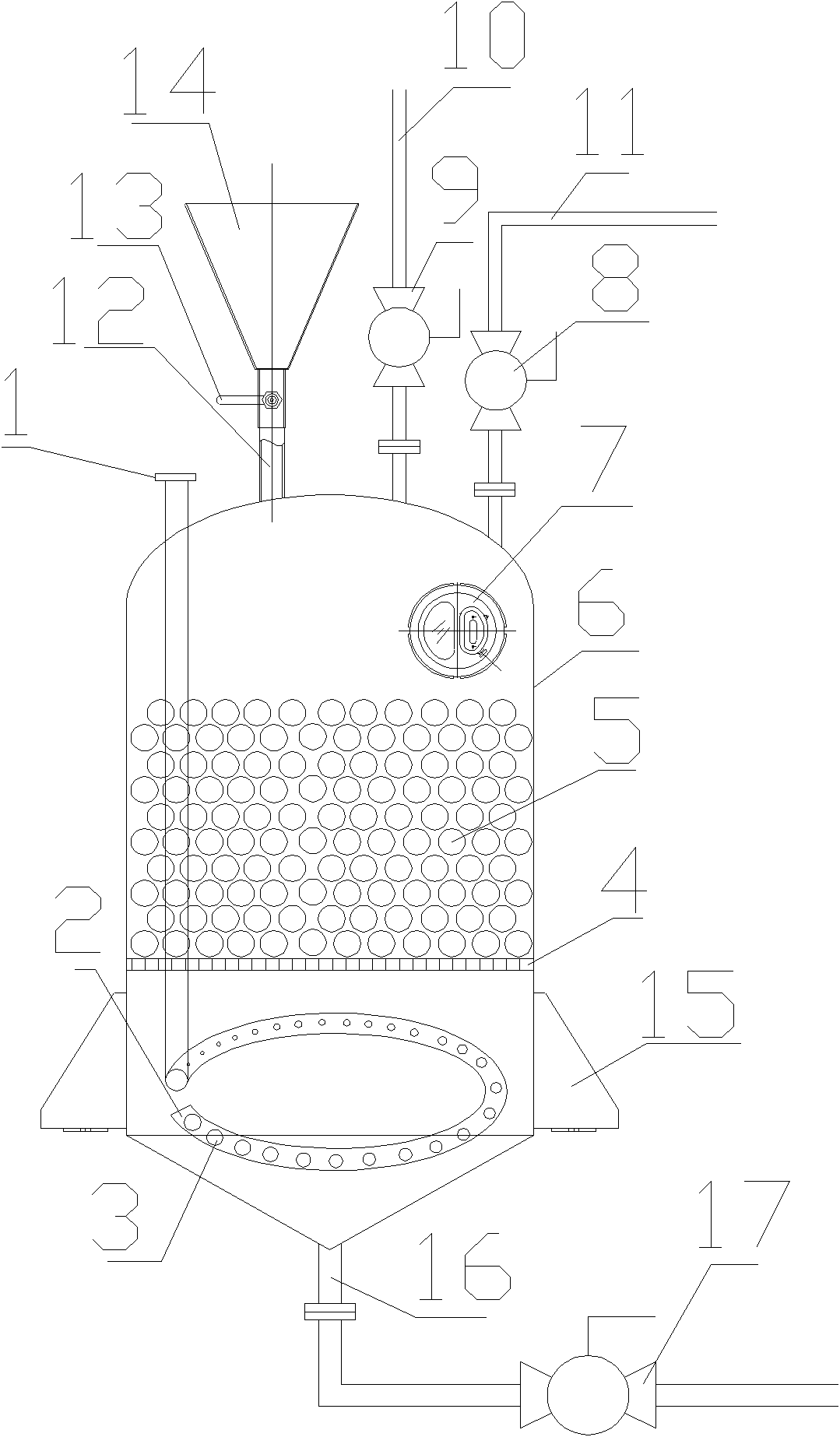

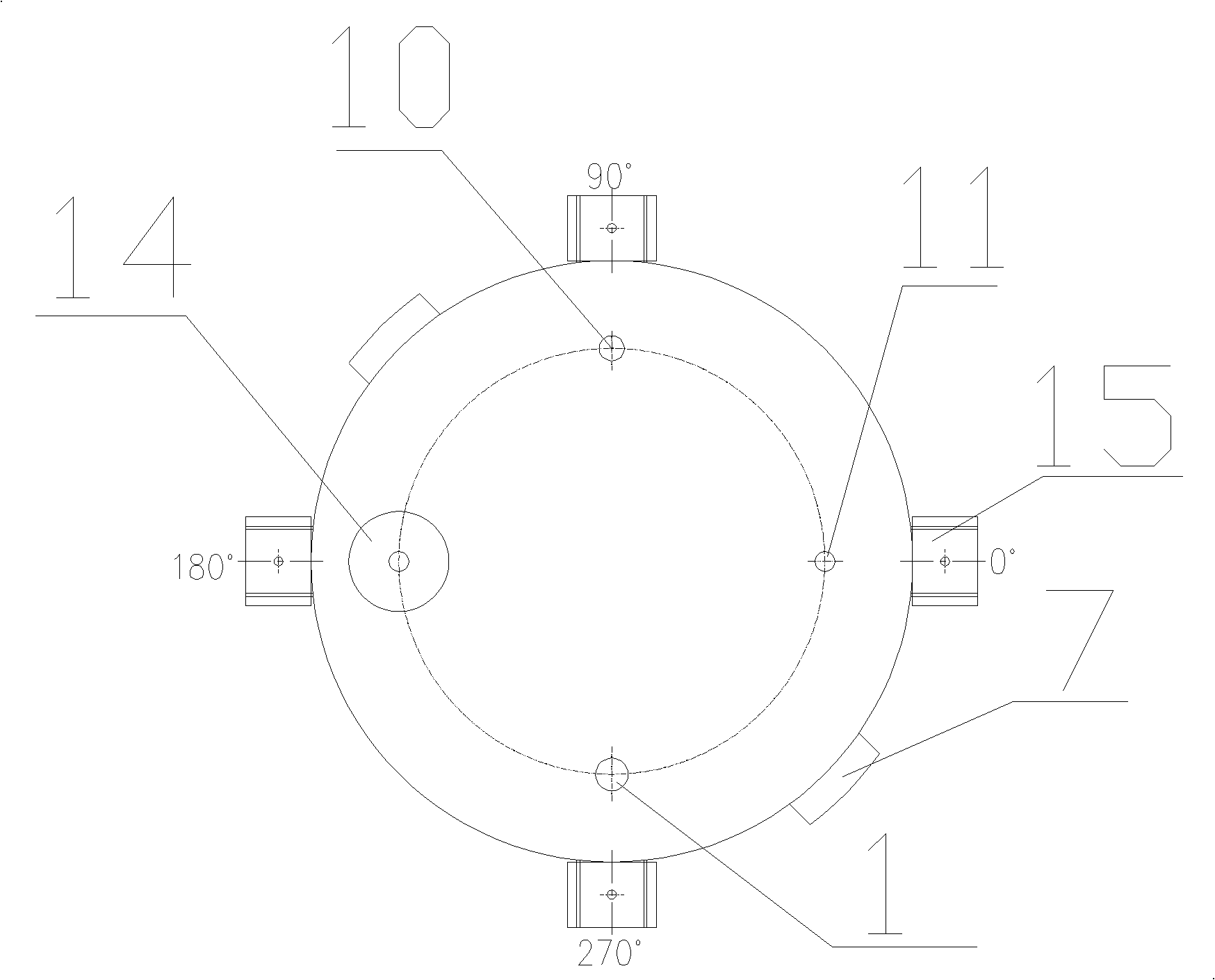

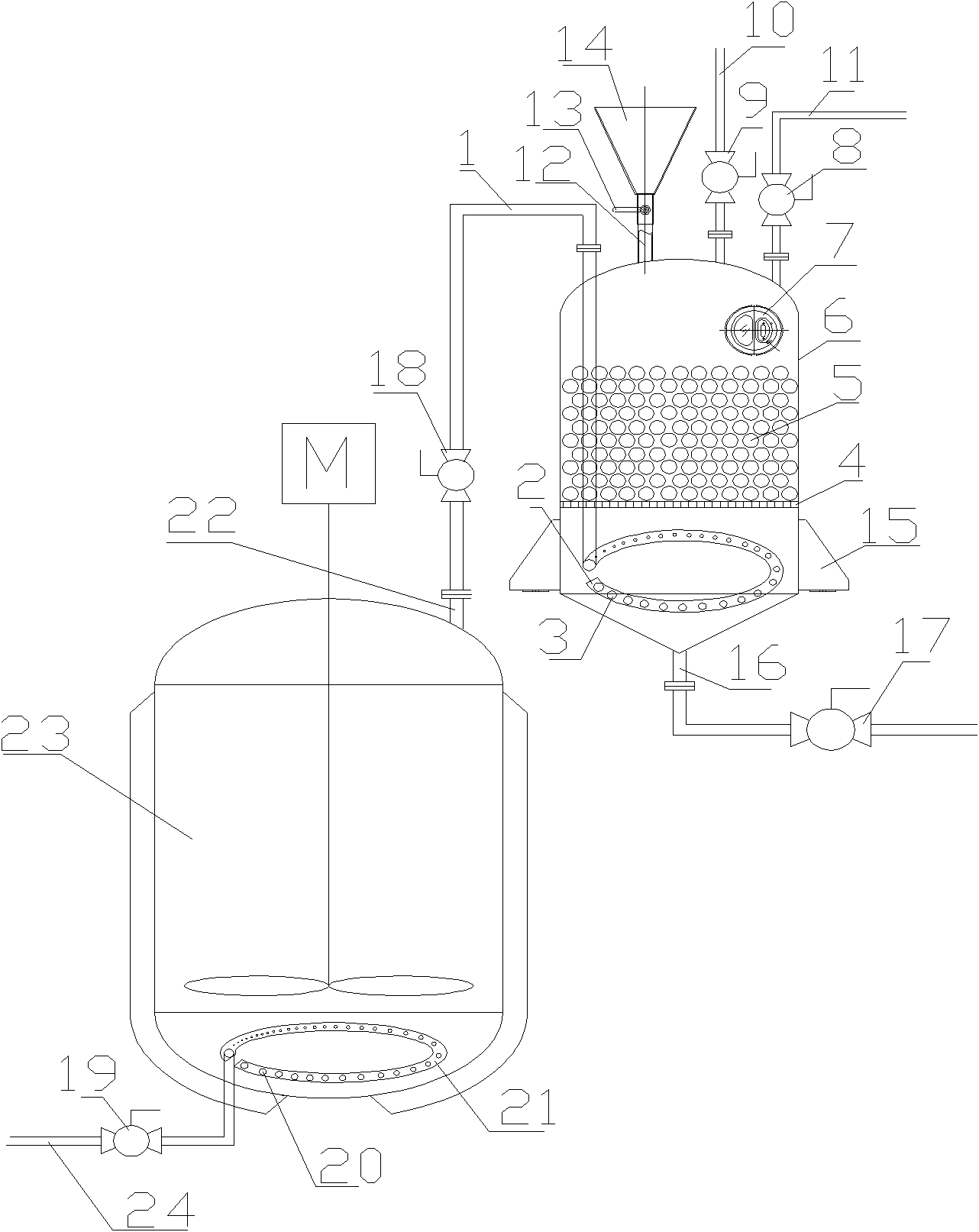

[0033] figure 1It is the front view of the gas washing recovery device for the preparation of polycarboxylate water reducer macromonomer according to the present invention. The device consists of the following parts: as shown in the figure, the mixed gas inlet pipe 1 is directly connected to the lower part from the top of the barrel body of the gas washing recovery device, and is connected with the coil tube 2 located at the lower part of the barrel body. Small holes 3 of different sizes, the diameter of the small hole 3 in the lower part of the coil increases gradually from the inlet end to the other end, and the small hole 3 in the lower part of the coil is located at the bottom of the coil 2. The grid 4 is positioned above the coil 2, the ceramic balls or glass balls 5 are placed above the grid 4, and the viewing mirror 7 is installed outside the staving, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com