Method for preparing tungsten oxide filled phthalic acid nano tube

A titanate nanotube and nanotube technology, applied in chemical instruments and methods, catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of reduced photocatalytic efficiency and low efficiency, etc. Achieve high specific surface area, broad application space, and improve the effect of optoelectronics

Active Publication Date: 2011-06-15

ZHEJIANG SCI-TECH UNIV

View PDF2 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

First, this high-energy-band material (Eg≈3.2eV) can only be excited by ultraviolet light with a wavelength less than 387.5nm

Since ultraviolet light only accounts for 3%~5% of sunlight, the efficiency of the material itself in the utilization of sunlight is low.

Second, the photogenerated electrons-holes on the surface are easy to recombine, which leads to the reduction of its photocatalytic efficiency.

So far, people have conducted in-depth and extensive research on the synthesis method, composition, thermal stability and formation mechanism of phthalic acid nanotubes. However, the research on the multi-component doping modification and physical properties of phthalic acid nanotubes still very little

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

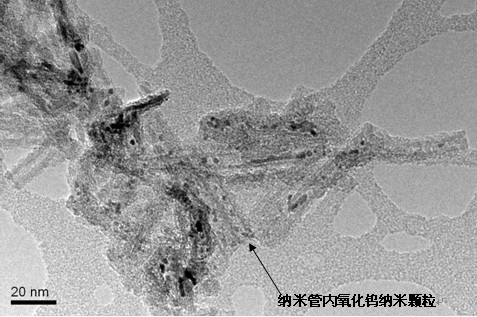

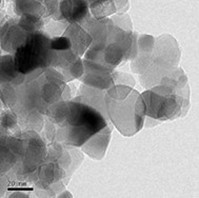

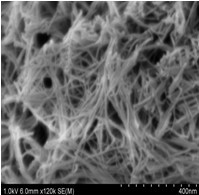

The invention discloses a method for preparing a tungsten oxide filled phthalic acid nano tube. The method comprises the following processes of: 1, performing dipping and filling by using capillarity: selecting a purchased or self-made phthalic acid nano tube, adding 10 to 50 milliliters of deionized water and 0.5 to 10 grams of sodium tungstate (NaWO4.2H2O) into the phthalic acid nano tube, performing full stirring and dissolution, performing ultrasonic treatment for 0.5 to 5 hours, and stirring the solution for 1 to 40 hours; 2, sealing the tube: adding 5 to 20 milliliters of 0.1 to 2mol / L HCl into the solution, and quickly stirring the solution for 3 to 10 minutes at the revolution speed of 700 to 1,000rpm; and 3, performing reaction in the tube: transferring the suspension to a centrifugal tube, centrifuging the suspension for 5 to 20 minutes at the centrifuging speed of 4,000 to 8,000rpm, pouring the centrifuged solution, adding the sediment into 5 to 20 milliliters of 1 to 2mol / L HCl, continuously performing reaction for 1 to 5 hours with stirring to react the un-reacted sodium tungstate in the tube into tungstic acid, washing the product for 1 to 5 times by using deionized water and 1 to 3 times by using alcohol to remove the sodium tungstate outside the nano tube after the reaction is completed, and finally drying the product at the temperature of between 60 and 80 DEG C to obtain a one-dimensional composite nano material, namely the tungsten oxide filled phthalic acid nano tube product.

Description

A kind of preparation method of tungsten oxide filled phthalic acid nanotube technical field The invention relates to a method for preparing tungsten oxide nanoparticle-filled titanate nanotubes by using a high specific surface area titanate nanotube as a carrier and sodium tungstate as a precursor through an impregnation-precipitation method. Background technique Since the report of Japanese scholars Fujishima and Honda in 1972, TiO2 photocatalytic materials have been widely used in wastewater treatment, air purification, sterilization and self-cleaning due to their strong oxidation ability, high catalytic activity, stable physical and chemical properties, low price and non-toxicity. has been at the core of research. However, with the deepening of the research, the researchers found that TiO2 itself has two major defects that need to be resolved. First, this high-band material (Eg≈3.2eV) can only be excited by ultraviolet light with a wavelength less than 387.5nm. Since...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01J23/30B01J21/06B01J35/02B01J37/02B01J35/00

Inventor 王晟王騊高艳龙

Owner ZHEJIANG SCI-TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com