Multi-spindle U drill gang spindle box and U drill gang high-speed numerical control drilling machine

A spindle box and spindle technology, which is applied in drilling/drilling equipment, parts of boring machine/drilling machine, boring/drilling, etc. It can solve the problems of not being able to meet high efficiency and high quality, so as to improve the finish of hole processing and extend the Tool durability, good performance results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

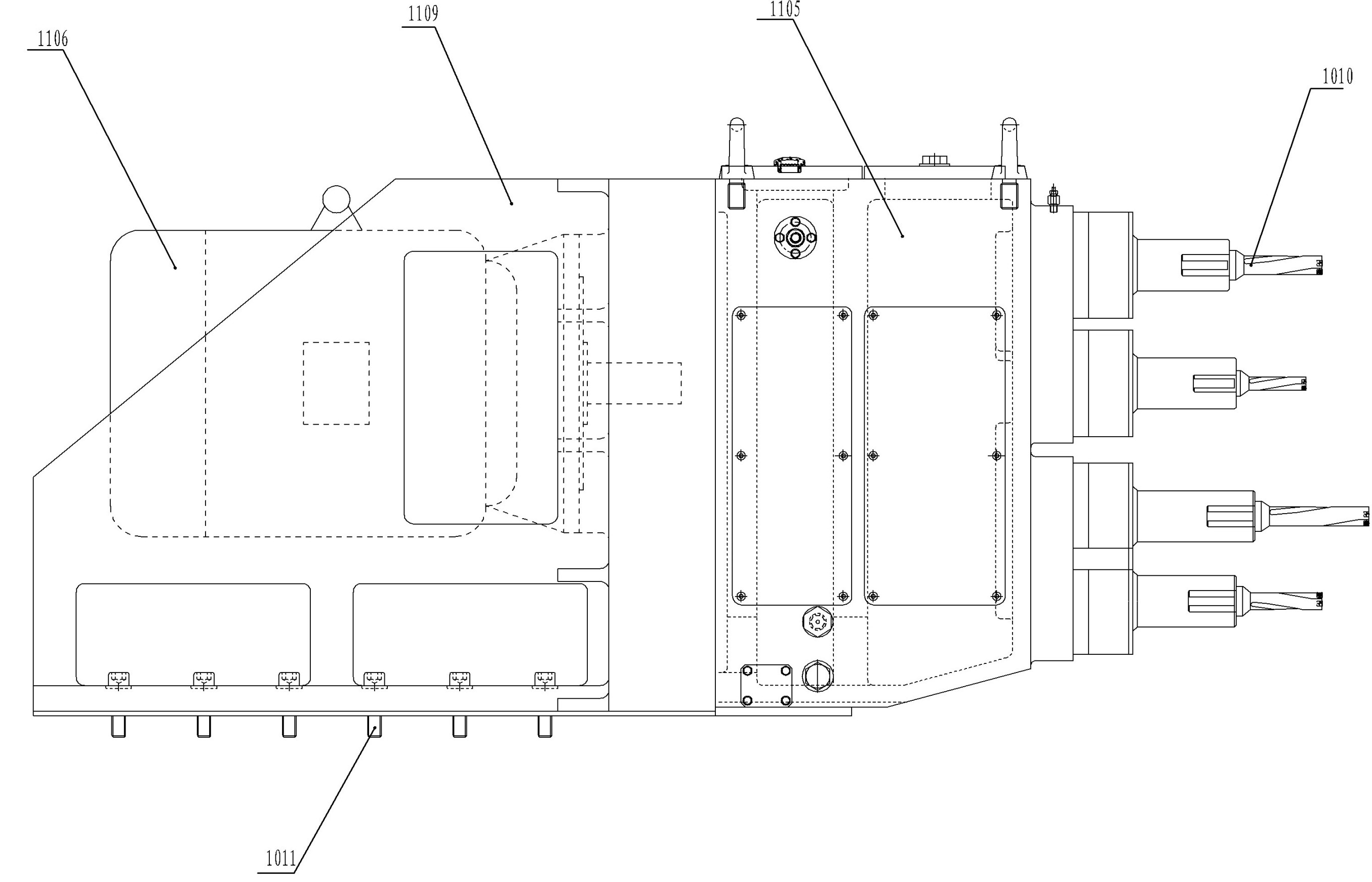

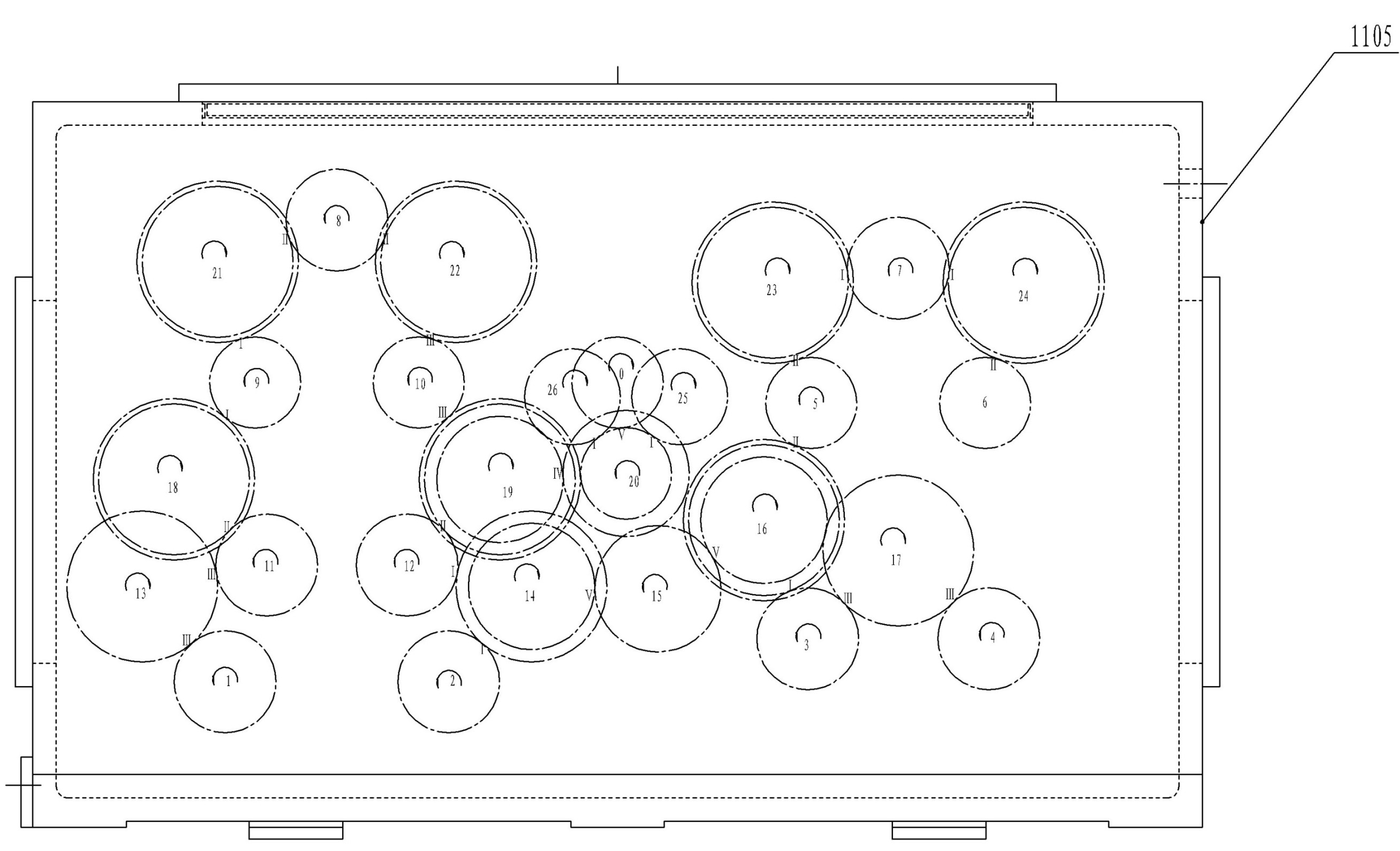

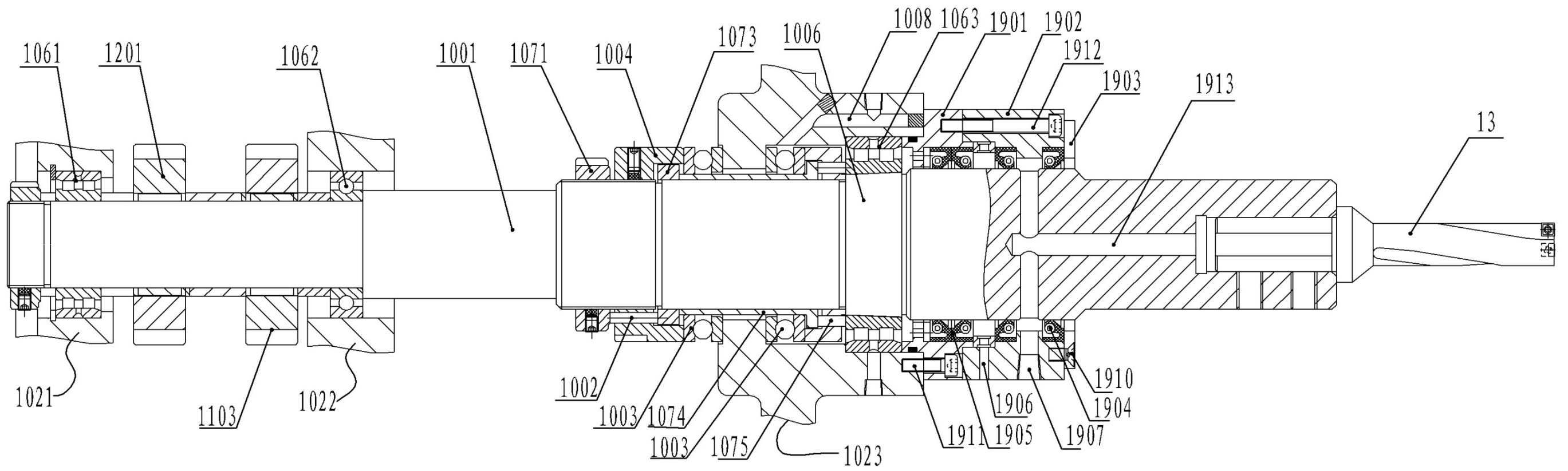

[0027] Embodiment one: see figure 1 — Figure 7 , a multi-axis U drill group spindle box, the spindle box includes a box body, a bracket fixed on the drilling machine is arranged on the rear side of the box body, the motor is horizontally fixed on the bracket, and the output shaft of the motor is inserted into the inside of the box body as The main transmission shaft is represented by the O axis in the figure. Wherein the box body is vertically provided with three layers of support walls respectively, wherein the support walls on both sides outside can be the side walls of the box body, and a plurality of U drill spindles are horizontally installed in the shaft holes of each support wall through three corresponding bearings respectively, In the figure, the support wall close to the motor is labeled 1021, the middle support wall is 1022, and the support wall close to the drill bit is 1023. The support structure of multiple support walls and multiple bearings can improve the st...

Embodiment 2

[0078] Embodiment 2: Referring to the figure, a U-drill group high-speed CNC drilling machine includes a machine base, a horizontal slide table (a mechanical slide table in this embodiment), a longitudinal slide table (a numerical control slide table in this embodiment), and a water cooling mechanism And the chip catcher also includes the headstock of the multi-axis U drill group described in the first embodiment. The bracket of the spindle box of the multi-axis U drill group is fixed on the horizontal slide table, and the slide between the horizontal slide table and the machine base is slidably connected by guide wheels and guide rails. There is a threaded rod, and the threaded rod is matched with the nut bushing at the bottom of the headstock support of the multi-axis U drill group. Through the rotation of the drive motor, the horizontal sliding table can be translated to a designated position as required. In this embodiment, the driving motor of the horizontal slide table i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap