Modified phenolic aldehyde foam plate and composite plate thereof as well as method for manufacturing modified phenolic aldehyde foam plate and composite plate

A phenolic foam board and phenolic foam technology, which are applied in chemical instruments and methods, building structures, lamination devices, etc., can solve the problems of poor compressive strength, easy pulverization, easy dusting, etc. Dust and not easy to peel off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment one modified phenolic foam board

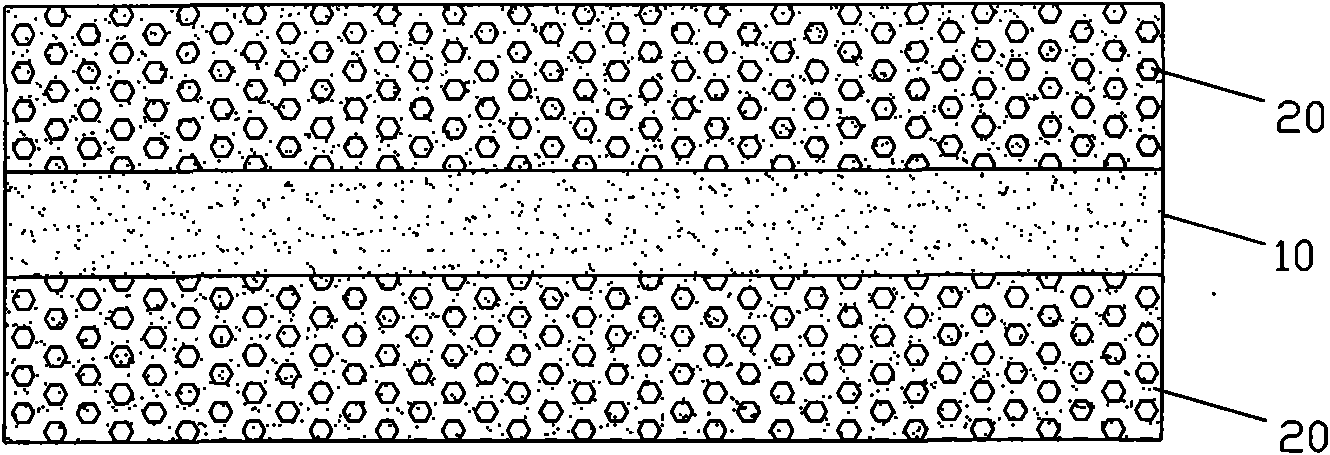

[0020] A kind of modified phenolic foam board of the present invention, with reference to figure 1 , including a layer of phenolic foam layer 10, the upper and lower surfaces of the phenolic foam layer 10 are respectively filled with a layer of three-dimensional fluffy material layer 20, the phenolic foam layer 10 is filled into the gaps of the three-dimensional fluffy material layer 20, and the three-dimensional fluffy material layer 20 form a one-piece structure, so that the modified phenolic foam board of the present invention has the advantages of good toughness, high strength, not easy to generate dust, and not easy to pulverize.

[0021] In the present invention, the thickness of the phenolic foam layer 10 is preferably 20-100 mm, and the thickness of the three-dimensional fluffy material layer 20 is preferably 2-50 mm. The three-dimensional fluffy material layer 20 is glass fiber, chemical fiber, and sprayed cotton, ...

Embodiment 2

[0023] The manufacture method of embodiment two modified phenolic foam boards

[0024] The manufacturing method of a kind of modified phenolic foam board of the present invention comprises the following steps: put the three-dimensional fluffy material on the auxiliary surface layer material through the pressure roller, and send it into the upper and lower parts of the continuous phenolic foam board production device or the shaping mold cavity On the lower surface, the expandable phenolic resin composition is poured on the three-dimensional fluffy material stacked with the auxiliary surface layer material, heated, foamed and shaped, then matured and demoulded, and the auxiliary surface layer material is removed to obtain a modified phenolic foam board .

[0025] In the present invention, the expandable phenolic resin composite material is preferably composed of components in the following weight ratio: phenolic resin: surfactant: foaming agent: curing agent=100: (1~5): (1~10) ...

Embodiment 3

[0026] Example three Modified phenolic foam composite board

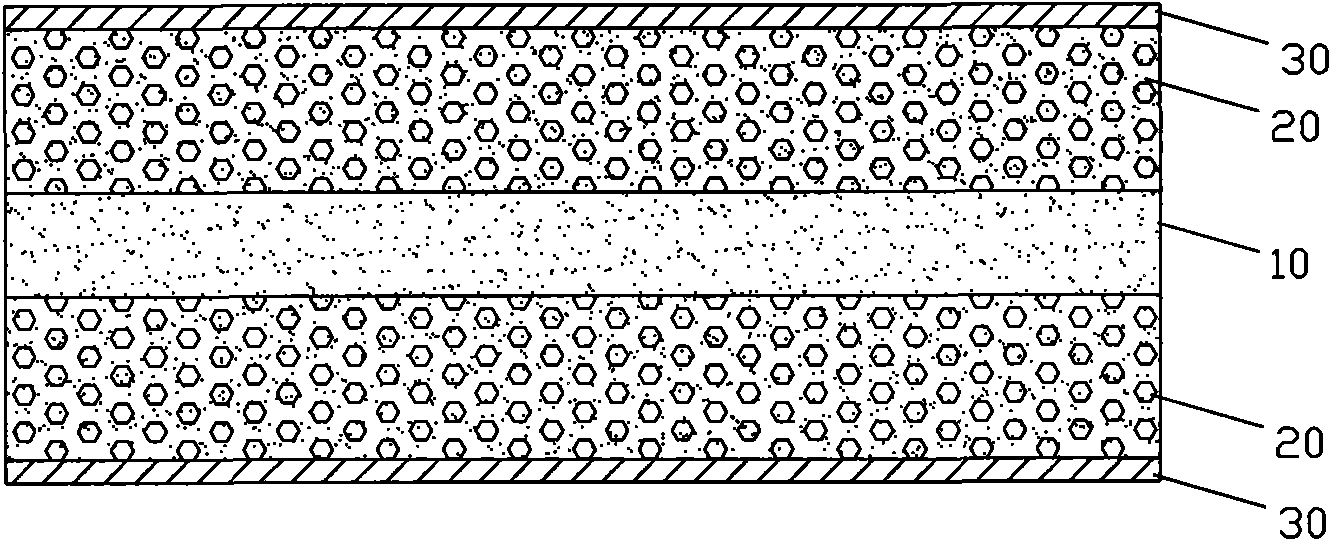

[0027] refer to figure 2 , a kind of modified phenolic foam composite board of the present invention, comprises one deck phenolic foam layer 10, is filled with one deck three-dimensional fluffy material layer 20 respectively on the upper and lower surface of this phenolic foam layer 10, in upper and lower three-dimensional fluffy material layer The surface of 20 is respectively compounded with one deck composite surface layer 30 with glue.

[0028] In the present invention, the composite surface layer 30 is aluminum foil, aluminum foil paper, kraft paper, color steel plate, galvanized steel plate, tinplate plate, stainless steel plate, glass magnesium plate, calcium silicate plate or cement pressure plate, and its thickness is preferably 0.05-5 mm. The glue used for compounding is preferably one or a combination of polyurethane glue, phenolic resin glue, styrene-butadiene latex, and acrylic glue.

[0029] The com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com