Dye wastewater cyclic utilization device and method based on electrolysis and lamination technologies

A technology of printing and dyeing wastewater and membrane technology, applied in chemical instruments and methods, textile industry wastewater treatment, water pollutants, etc., can solve the problems of high recycling cost, large wastewater discharge, waste of water resources, etc., and save material consumption. , The effect of less wastewater discharge and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

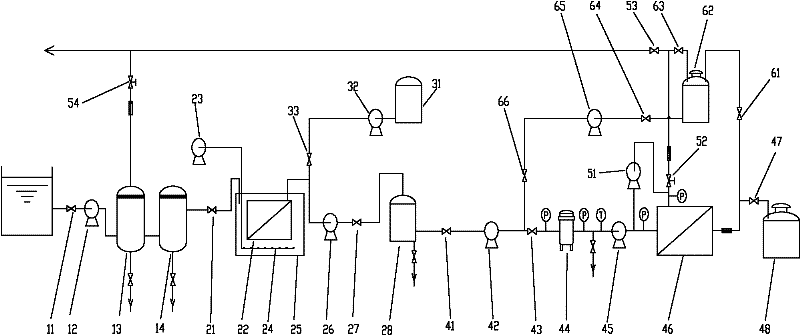

[0056] 150 tons / day printing and dyeing advanced treatment wastewater purification and reclaimed water reuse method.

[0057] The measured indexes of the printing and dyeing advanced treatment wastewater are shown in Table 1.

[0058] Table 1

[0059] serial number

project

unit

measured value

serial number

project

unit

measured value

1

COD Cr

mg / L

430

5

‰

6.6

2

SS

mg / L

115

6

pH

8.1

3

NTU

9

7

μS / cm

7350

4

Chroma

70

[0060] After 150 tons of printing and dyeing advanced treatment wastewater is extracted by the water supply pump 12 at a flow rate of 7.5T / h, it is input into the nano-catalytic electrolysis machine 13, and the nano-catalytic electrolyzed water directly enters the precipitation tank 14, and after neutralization and precipitat...

Embodiment 2

[0069] 3000 tons / day printing and dyeing advanced treatment wastewater purification and reclaimed water reuse method.

[0070] The indicators of the advanced printing and dyeing wastewater treatment are as shown in Table 4 after determination of the printing and dyeing advanced treatment wastewater:

[0071] Table 4

[0072] serial number

project

unit

measured value

serial number

project

unit

measured value

1

COD Cr

mg / L

156

5

‰

3.1

2

SS

mg / L

60

6

pH

8.3

3

NTU

8

7

μS / cm

7100

4

Chroma

200

[0073] The printing and dyeing advanced treatment wastewater is extracted by the water supply pump 12 at a flow rate of 150T / h, and then input into the nano-catalysis electrolysis machine 13. The nano-catalysis electrolysis water directly enters the pr...

Embodiment 3

[0082] 6000 tons / day printing and dyeing advanced treatment wastewater purification and reclaimed water reuse method.

[0083] The indicators of the purification and reclaimed water reuse device for advanced printing and dyeing wastewater treatment are shown in Table 7.

[0084] Table 7

[0085] serial number

project

unit

measured value

serial number

project

unit

measured value

1

COD Cr

mg / L

391

4

‰

0.9

2

SS

mg / L

190

5

pH

7.7

3

NTU

8.4

6

μS / cm

8100

[0086] After the printing and dyeing advanced treatment wastewater is extracted by the water supply pump 12 at a flow rate of 300T / h, it is input into the nano-catalysis electrolysis machine 13, and the nano-catalysis electrolysis water directly enters the precipitation tank 14, and after precipitation, the solid impuri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com