Method for extracting and separating methylal-methanol mixture by using continuous countercurrent rotating disk

A technology for methylal and mixtures, which is applied in the field of continuous countercurrent liquid-liquid extraction and separation of methylal-methanol mixtures, can solve problems such as difficulty in obtaining high-purity methylal products, achieve high product purity and recovery, and reduce production costs Low, high-impact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

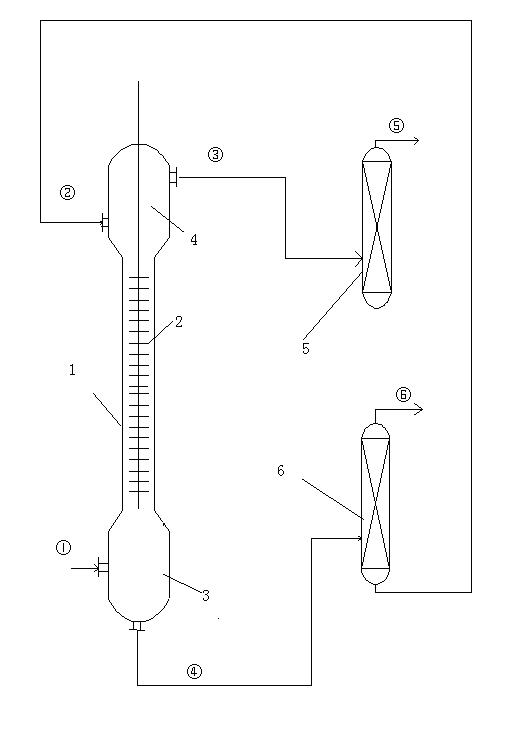

[0017] Embodiment 1, the continuous countercurrent rotary disk extraction and separation method of methylal-methanol mixed system, refer to figure 1 The process flow shown and the process parameters shown in Tables 1 and 2, the raw material (stream ①) is a mixture of methylal and methanol, wherein the mass content of methylal and methanol is 90% and 10% respectively, and the flow rate is 100Kg / h, enter the rotary extraction tower 1 from the bottom, due to the low density, the raw material is enriched upwards in the rotary extraction tower 1; the extractant (stream ②) is glycerol, including the recycled extractant after demethanolization, Enter from the top of the rotary disk extraction tower 1, flow from top to bottom in the rotary disk extraction tower 1, and the flow rate is 100Kg / h. Control the rotation speed of the stirring shaft of the turntable tower to 150 rpm, the two-phase liquid is fully contacted in the turntable tower under the agitation of the turntable 2, the ex...

Embodiment 2

[0027] Embodiment 2 is substantially the same as embodiment 1, but the extractant glycerol is changed into ethylene glycol.

Embodiment 3

[0028] Example 3 is basically the same as Example 1, but the extraction agent glycerol is changed to pentaerythritol, and the mass ratio of the extraction agent to the raw material is: 1.5:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com