Lac wax emulsion and preparation method thereof

A shellac wax and emulsion technology, applied in the field of shellac wax emulsion and its preparation, can solve the problems of increasing the amount of solid waste, narrow application mode of shellac wax, waste of shellac wax, etc. and use, suitable for large-scale promotion and application, and the effect of long shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1. Preparation of compound emulsifier

[0043] Add Tween-80, Span-80, and triethanolamine into the reaction container, stir evenly, and prepare a compound emulsifier for future use, wherein, the weight ratio of Tween-80, Span-80, and triethanolamine is 69.8:14.3 : 15.9.

[0044] 2. Prepare shellac wax-emulsifier mixture

[0045] Place a three-necked flask (volume: 250ml) equipped with a stirrer and a thermometer in a HH-601 super constant temperature water bath, and add 10g of refined shellac wax to the three-necked flask, heat while stirring, heat up and maintain the temperature in the water bath 90°C until the shellac wax melts, and the stirring rate is 50r / min;

[0046] Keeping the temperature at 90°C, adding compound emulsifier (16g) to the melted shellac wax, stirring evenly to obtain shellac wax-emulsifier mixture, wherein the weight of shellac wax and compound emulsifier The ratio is 1:1.6, and the stirring speed is 50r / min.

[0047]3. Preparation of lac wax ...

Embodiment 2

[0053] In the process of preparing the compound emulsifier, except that the weight ratio of Tween-80, Span-80 and triethanolamine is: 78:17:5, the rest are the same as in Example 1;

[0054] In the process of preparing the shellac wax-emulsifier mixture, except that the temperature is 88° C., the weight ratio of the shellac wax to the compounded emulsifier is 1: 1.5, and the stirring rate is 100 rpm, all the other are the same as in Example 1;

[0055] In the process of preparing shellac wax colostrum, except that the temperature is 88°C, the stirring rate is 100r / min, the stirring time is 30min, and the weight ratio of the first batch of water to shellac wax is 0.2:1, the rest are the same as in Example 1;

[0056] During the emulsification and phase inversion process, except that the temperature was 88°C, the stirring speed was 1000r / min, the stirring time was 60min, and the weight ratio of the second batch of water to shellac wax was 9.8:1, the rest were the same as in Examp...

Embodiment 3

[0058] Except that the weight ratio of Tween-80, Span-80 and triethanolamine is: 72:17:5 in the process of preparing compound emulsifier, the rest is the same as Example 1;

[0059] In the process of preparing the shellac wax-emulsifier mixture, except that the temperature is 85° C., the weight ratio of the shellac wax to the compounded emulsifier is 1: 1.6, and the stirring rate is 50 rpm, all the other are the same as in Example 1;

[0060] In the process of preparing shellac wax colostrum, except that the temperature is 85°C, the stirring rate is 20r / min, the stirring time is 90min, the weight ratio of the first batch of water and shellac wax is 0.6: 1, and the rest are the same as in Example 1;

[0061] During the emulsification and phase inversion process, except that the temperature was 85°C, the stirring speed was 550r / min, the stirring time was 60min, and the weight ratio of the second batch of water to shellac wax was 11.4:1, the rest were the same as in Example 1.

PUM

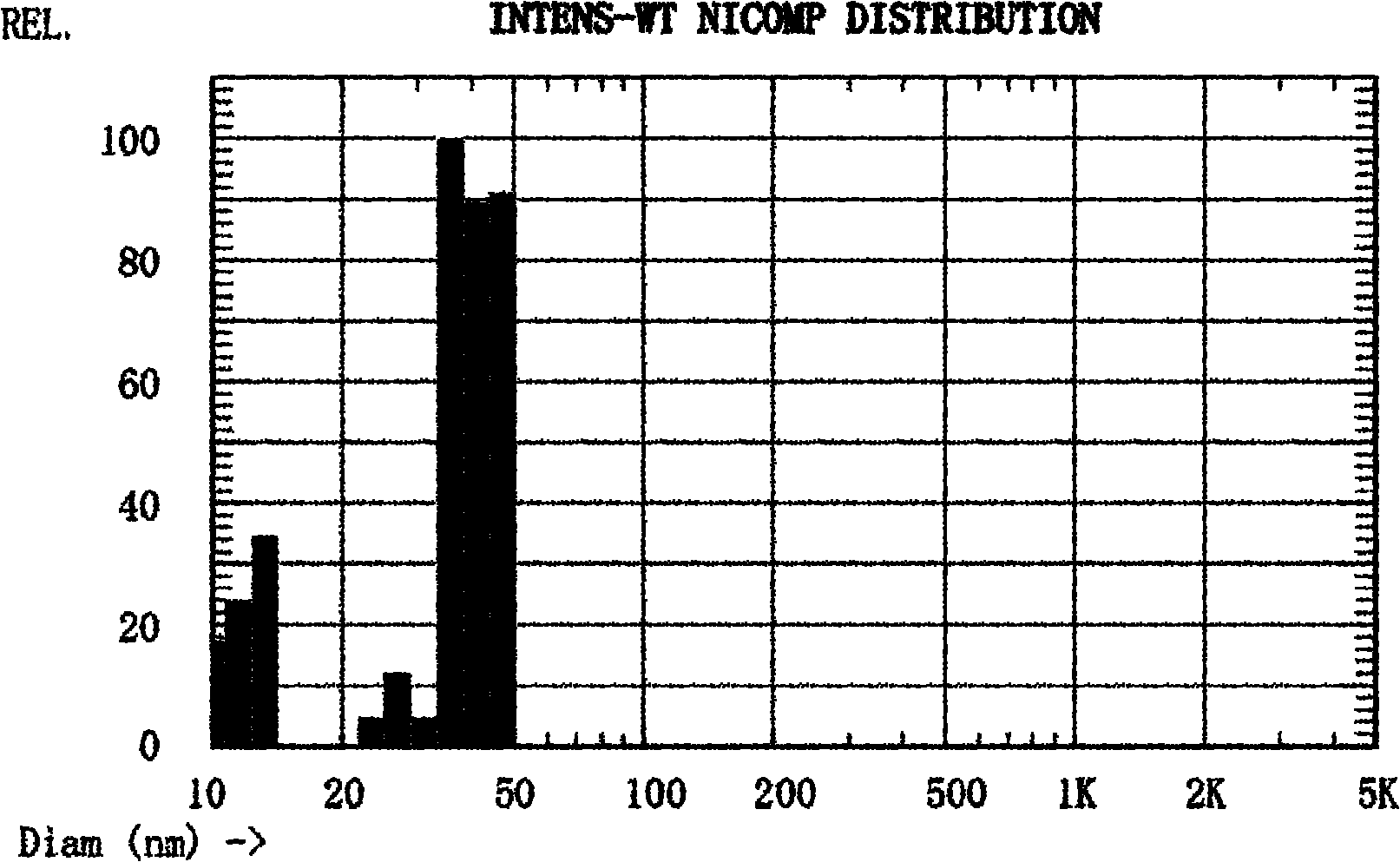

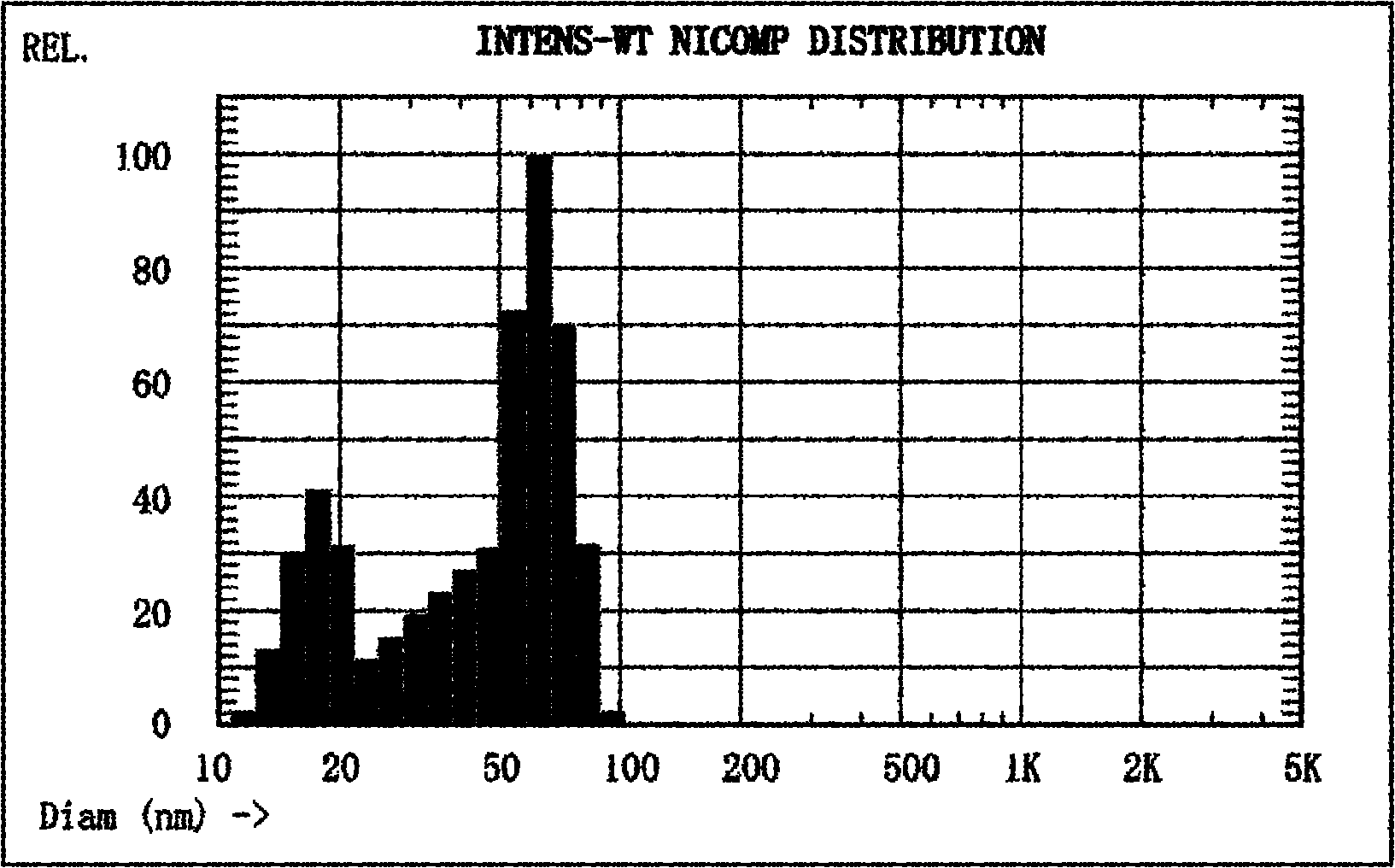

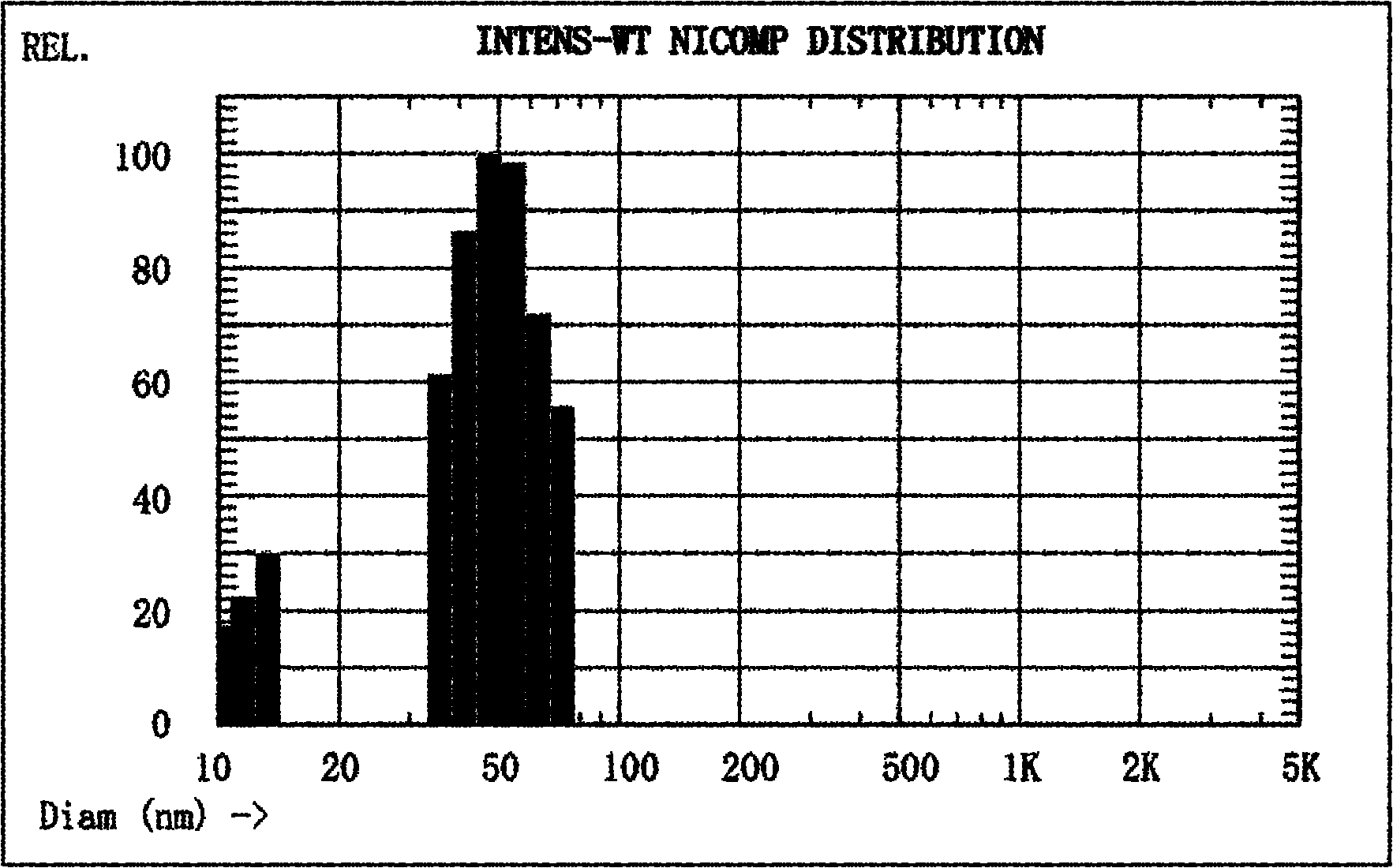

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com