Thick-film photoresist cleaning solution and cleaning method thereof

A technology of cleaning solution and photoresist, which is applied in the processing of photosensitive materials, etc., can solve the problems of insufficient cleaning ability, strong corrosion of semiconductor wafer patterns and substrates, etc., and achieve the effect of inhibiting corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

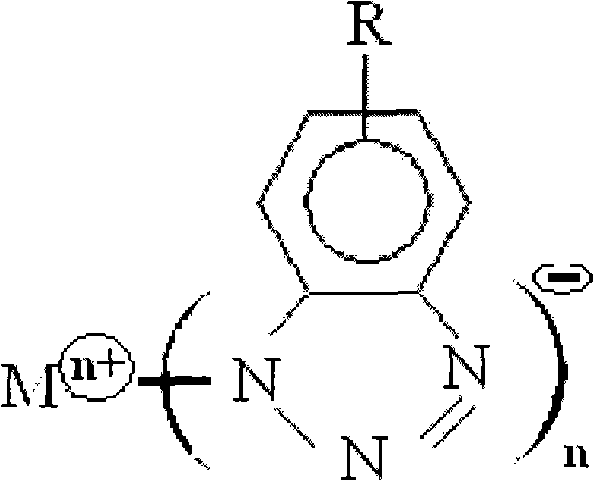

Image

Examples

Embodiment Construction

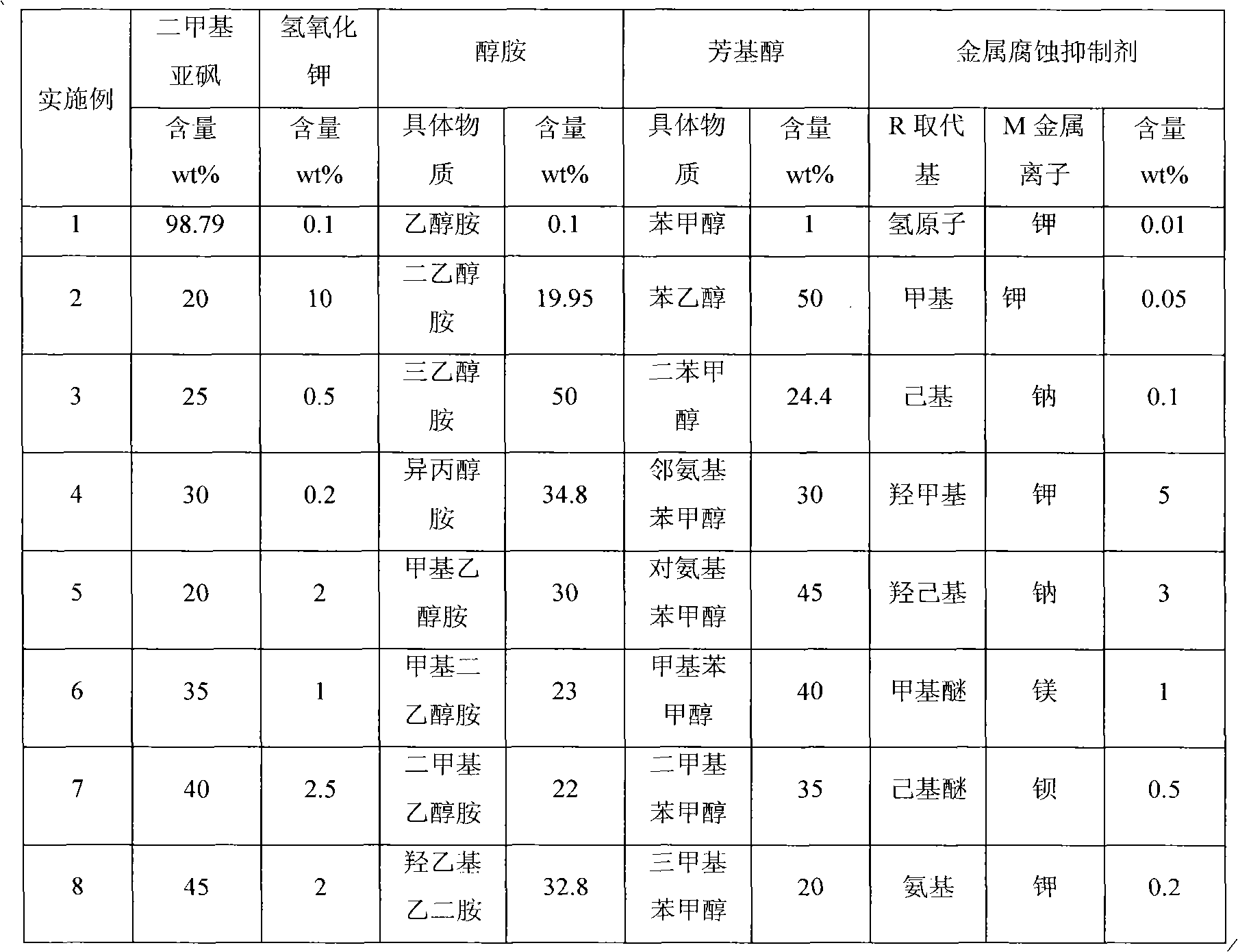

[0022] The present invention will be further described below through specific embodiments. The cleaning solution of the present invention can be obtained by uniformly mixing according to the distribution ratio of the components in the table.

[0023] Component and content of cleaning agent in table 1 embodiment 1~25

[0024]

[0025]

[0026] Table 2 part embodiment and comparative example formula

[0027]

[0028] Note: NA means that this component was not added.

[0029] In order to further illustrate the effect and principle of the present invention, the solutions in Table 2 are specially configured, see Table 2 for details. It should be noted that comparative example 1' cannot form a uniform solution in Table 2, which shows that the solubility of KOH in dimethyl sulfoxide is less. Comparative Example 2' shows that adding aryl alcohol, i.e. benzyl alcohol, can improve the solubility of KOH in the system and form a uniform solution. In order to further investiga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com