Three-phase AC (Alternating Current) high-voltage vacuum contactor with long service life

A vacuum contactor and three-phase AC technology, which is applied in high-voltage air circuit breakers, high-voltage/high-current switches, electrical components, etc., can solve the problem that soft connections cannot be suitable for long-term and repeated working methods, and the amount of packaging in a single furnace is small. , spring compression and release unevenness, etc., to achieve the effect of improving mechanical life, high fatigue resistance, and reducing its own quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solutions of the present invention will be described below through specific embodiments and in conjunction with the accompanying drawings:

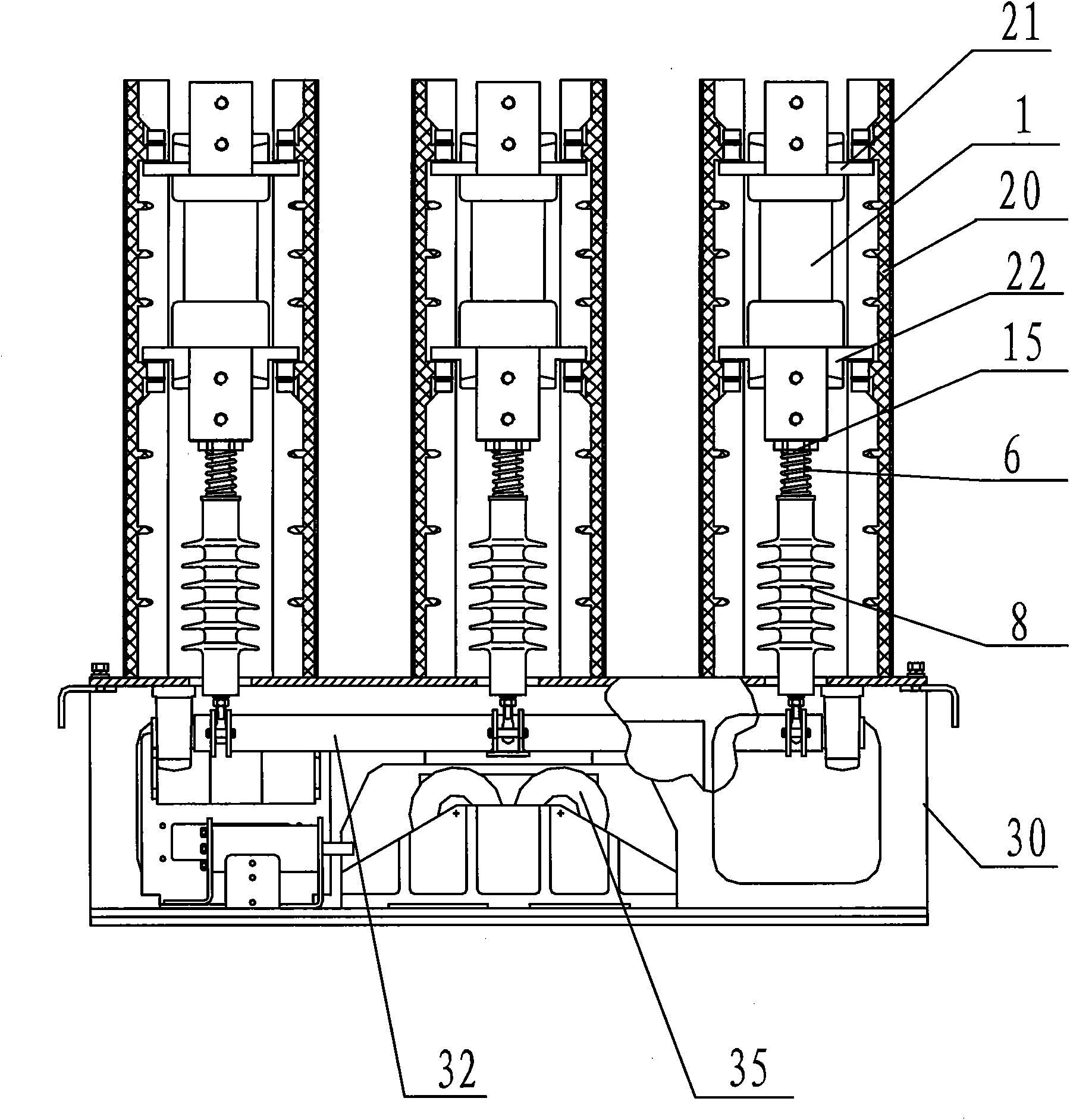

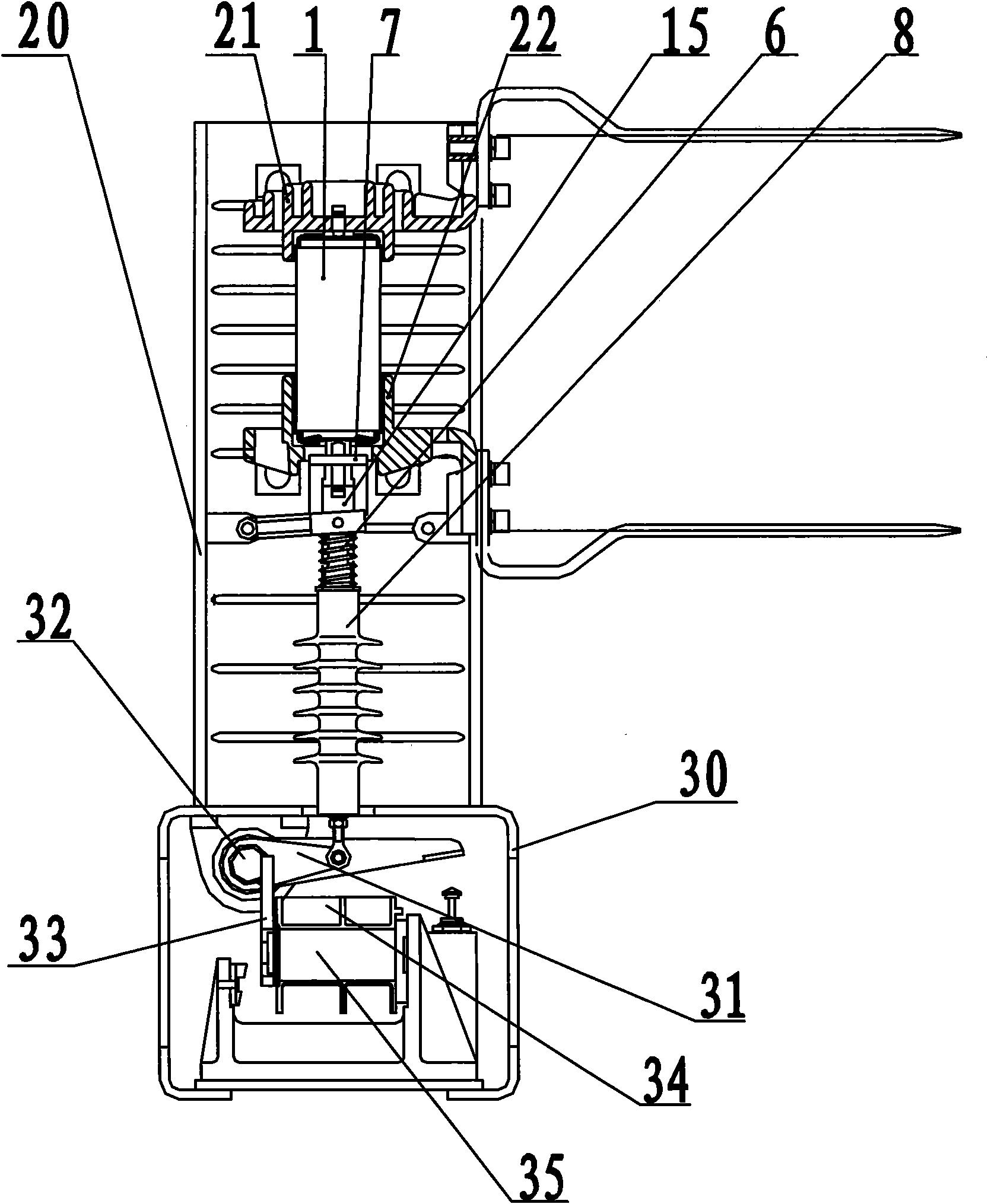

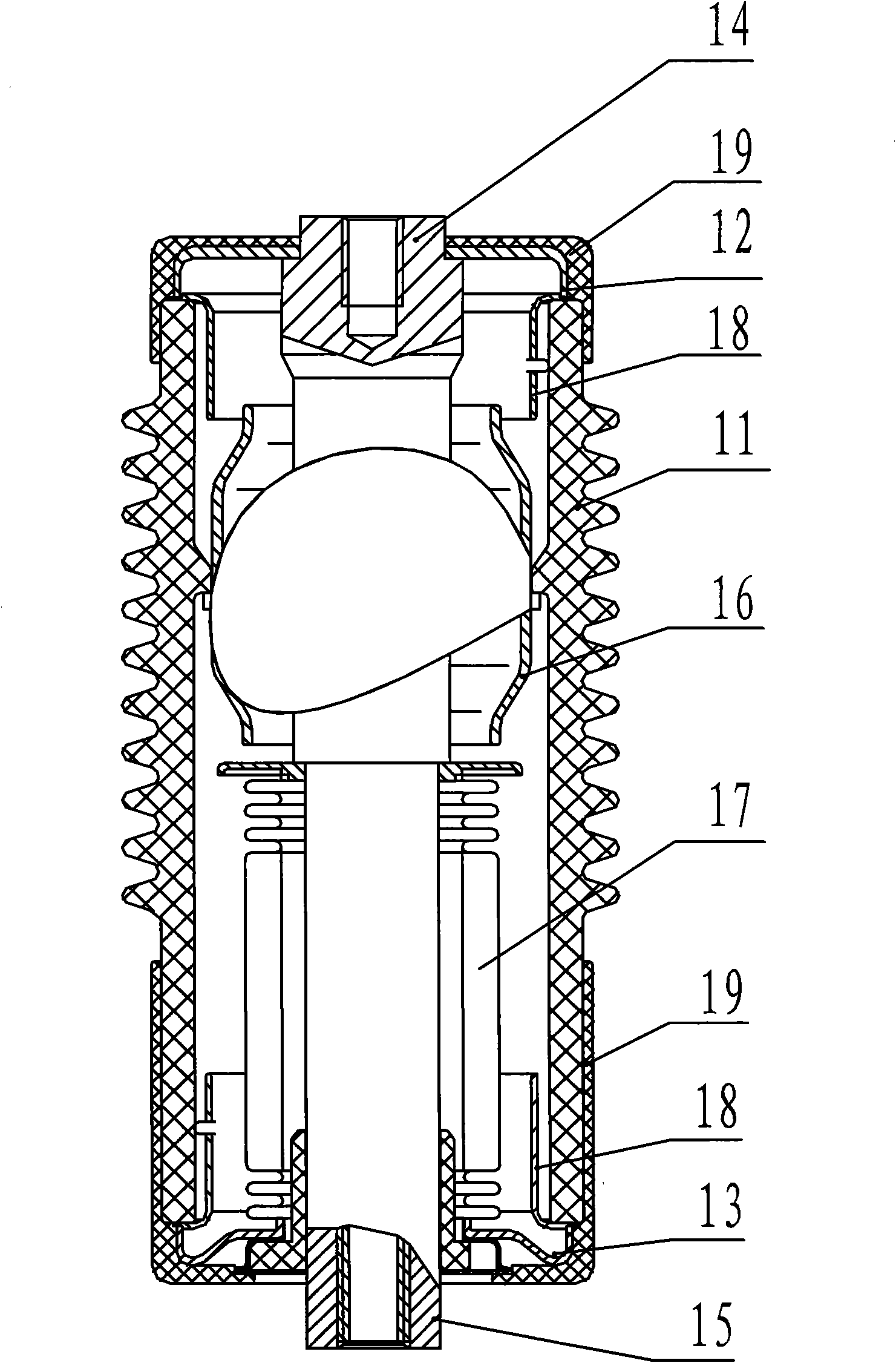

[0046] see Figure 1 to Figure 3 , The long-life three-phase AC high-voltage vacuum contactor of the present invention includes a vacuum interrupter 1, a conductive component and an electromagnetic operating mechanism arranged up and down. The vacuum interrupter 1 is vertically installed on the insulating partition 20; the vacuum interrupter 1 includes a shell 11, static and dynamic end covers 12, 13, and the shell 11 is an integral cylinder made of ceramic materials. The material of the movable end cover plates 12 and 13 is metal. The casing 11 and the static and movable end cover plates 12 and 13 constitute a closed container. The two ends of the closed container are also covered with silicone rubber sleeves 19 respectively. The container is provided with butt-jointed static and moving contacts (not shown in the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com