Method for treating organic wastewater containing high-concentration ammonia nitrogen

A technology for organic wastewater and treatment methods, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Impact resistance, the effect of reducing investment and operating costs, and reducing equipment size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

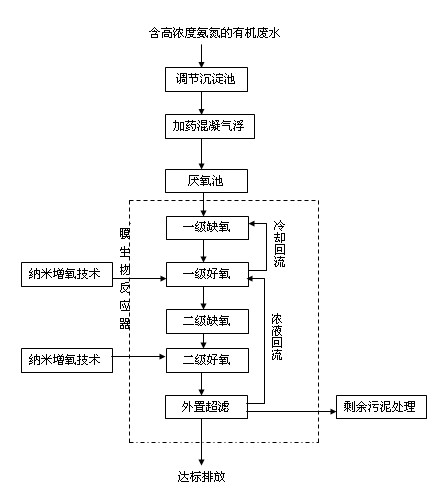

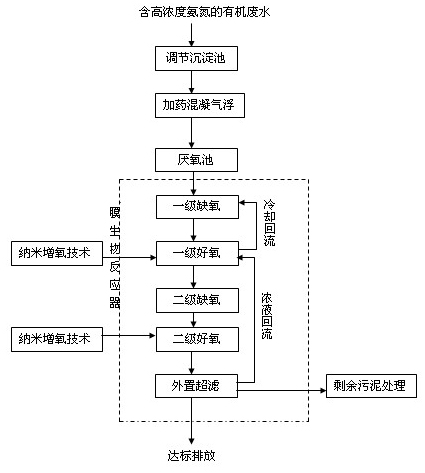

Image

Examples

Embodiment 1

[0021] A method for treating organic waste water containing high-concentration ammonia nitrogen is realized in the following steps:

[0022] The first step, preprocessing

[0023] The landfill leachate with an organic matter concentration of 12000-15000mg / LCODcr and an ammonia nitrogen concentration of 1500-2000mg / L first passes through the sedimentation tank to adjust the water quality and quantity, and settles the mud in the leachate; then enters the dosing coagulation air flotation tank to remove seepage Suspended solids, chroma, heavy metal ions and COD in the filtrate. The chemicals added to the coagulation flotation tank are PAC and PAM.

[0024] The second step, anaerobic treatment

[0025] The effluent from the coagulation air flotation tank enters the UASB reactor, the hydraulic retention time is 120h, and the removal rate of organic matter is 70%.

[0026] The third step, membrane bioreactor system

[0027] The effluent of UASB enters the membrane bioreaction sys...

Embodiment 2

[0029] A method for treating organic waste water containing high-concentration ammonia nitrogen is realized in the following steps:

[0030] The first step, preprocessing

[0031] The food processing wastewater with an organic matter concentration of 5000-6000mg / LCODcr and an ammonia nitrogen concentration of 400-500mg / L first passes through the sedimentation tank to adjust the water quality and quantity; then enters the dosing coagulation air flotation tank to remove suspended solids, chroma and COD in the wastewater . The agent added to the coagulation flotation tank is PFS.

[0032] The second step, anaerobic treatment

[0033] The effluent from the coagulation air flotation tank enters the UASB reactor, the hydraulic retention time is 40h, and the removal rate of organic matter is 60%.

[0034] The third step, membrane bioreactor system

[0035] The effluent from UASB enters the membrane bioreaction system for treatment. The concentration of organic matter in the influ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com