Preparation method of cis-hexahydroisoindoline

A kind of hexahydroisoindole, cis technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

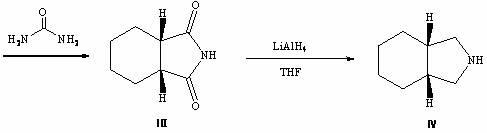

Method used

Image

Examples

Embodiment 1

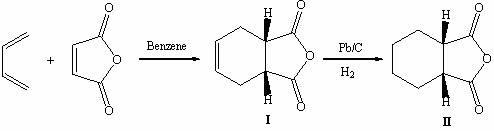

[0019] Step 1, the synthesis of cis-1,2,3,6-tetrahydrophthalic anhydride

[0020] Add maleic anhydride (98.0 g, 1.000 mol) into a reactor filled with dry benzene (250 mL), and feed 1,3-butadiene at a constant speed (0.6-0.8 L / min) under heating and stirring, and the reaction temperature After reaching 50 °C, heat for another 3 min, then stop heating, continue to feed 1,3-butadiene, react for 3.5 h, GC detects that the raw material maleic anhydride disappears, stop the reaction, stand at 0~5 °C for 12 h to crystallize , suction filtration, washing with petroleum ether, drying at ≤60 ℃ to constant weight, yield: 96.7%;

[0021] Step 2, the synthesis of cis-cyclohexanedicarboxylic anhydride

[0022] Dissolve cis-1,2,3,6-tetrahydrophthalic anhydride (178.3 g, 1.173 mol) in methanol (2000 mL), add 10% Pd / C (35.6 g), first vacuum, then use Replaced with hydrogen 3 times, introduced hydrogen, hydrogenated at normal pressure for 22 hours, filtered the reaction solution with suction,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com