Method for preparing polypyrrole doped molybdate

A polypyrrole and molybdate technology, which is applied in the electrolysis process, electrolysis components, electrolysis organic production, etc., can solve the problems of uneven product, low stability, complicated operation, etc., and achieves low investment, high stability, and simple handling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

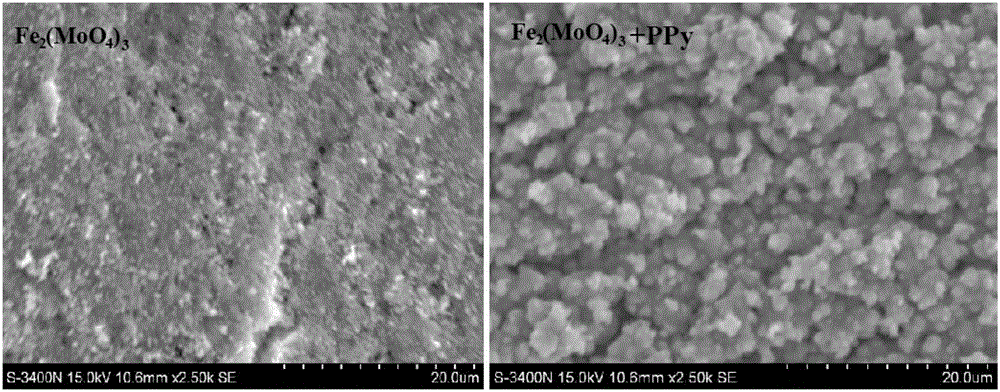

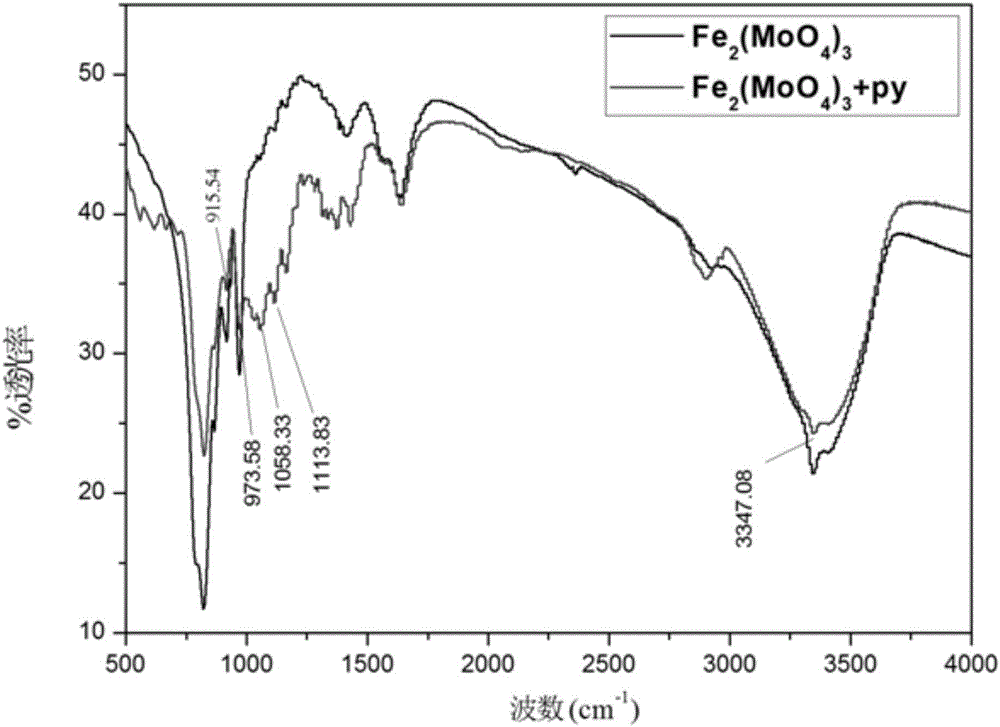

Method used

Image

Examples

Embodiment

[0034](1) With the anode soluble metal Fe as the anode, the inert electrode as the cathode, the mixed aqueous solution containing 90ml of sodium molybdate and pyrrole dispersed as the depolarizer as the anolyte, in the double-chamber electrolyzer with the cationic membrane as the diaphragm, Using constant current electrolysis, the control temperature range is from room temperature to 50°C to electrolyze the aqueous solution of sodium molybdate for 20 minutes, the inert electrode is a titanium mesh; the depolarizer is 0.01mol / L sodium chloride; the molybdenum The concentration of the aqueous sodium acid solution is 0.1mol / L; the concentration of the pyrrole dispersion is 5.4g / L; the acid solution is an aqueous hydrochloric acid solution with a concentration of 0.1mol / L; the cationic membrane is a perfluorosulfonic acid cation exchange membrane; The current of the constant current electrolysis is 0.6A, and the current density is 85.7mA / cm 2 ;

[0035] (2) After the electrolysis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com