Method for extracting and separating high-purity 1-Deoxynojirimycin from folium mori

A deoxynojirimycin, high-purity technology, applied in the field of extraction and separation of active components of traditional Chinese medicine, can solve the problems of low 1-deoxynojirimycin content, cost reduction, etc., and achieves the advantages of avoiding solvent residues, avoiding repeated operations, and operating safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

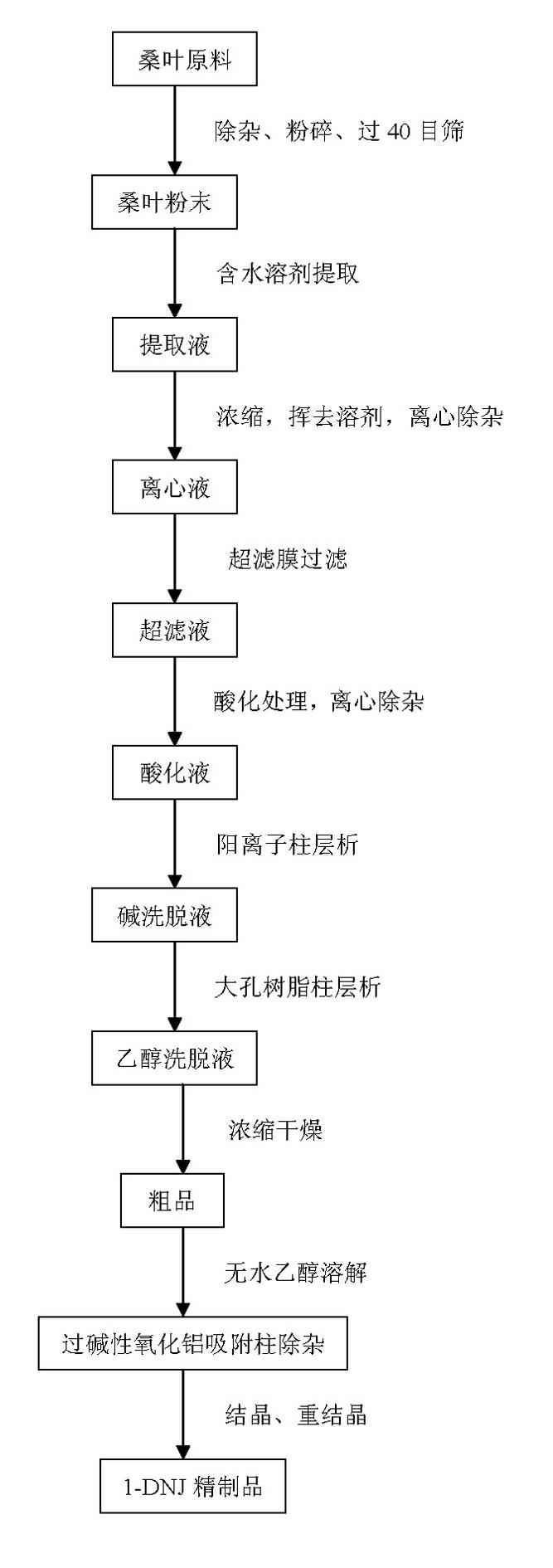

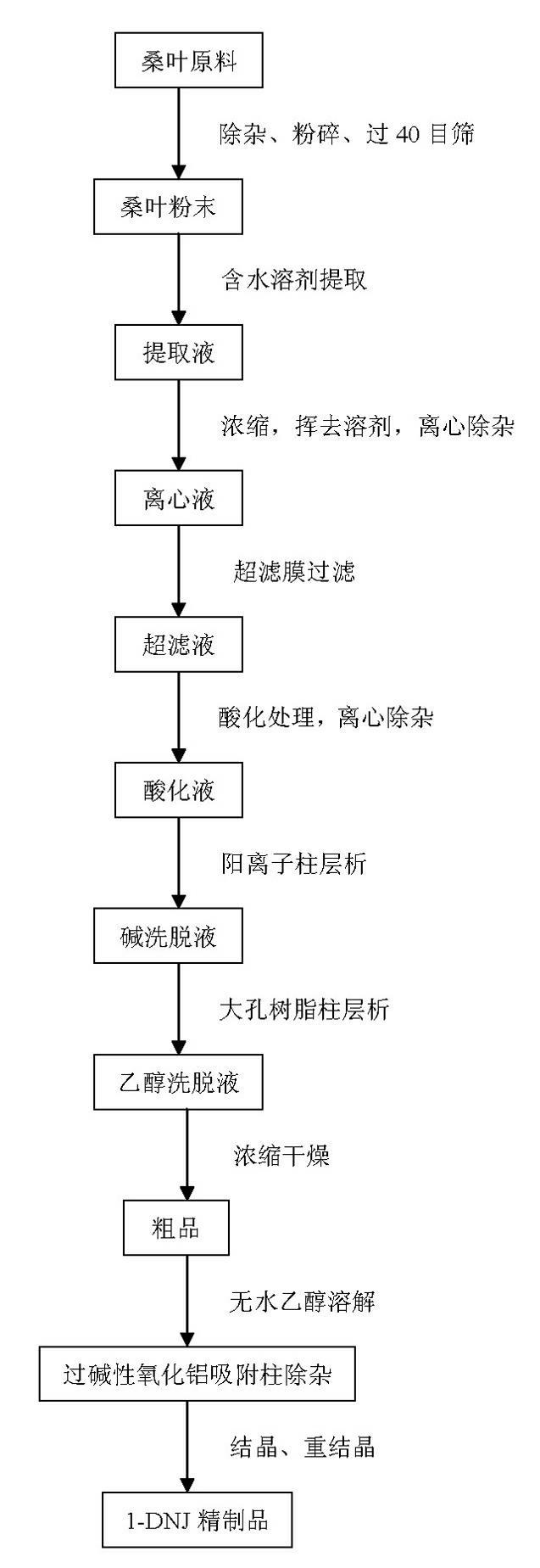

[0035] refer to figure 1 , a method for extracting and separating high-purity 1-deoxynojirimycin from mulberry leaves, comprising the following sequential steps:

[0036] The mulberry leaf medicinal material is pulverized and passed through a 40-mesh sieve;

[0037] Take 10kg of raw material powder and use 75% ethanol to extract twice at 60°C (the solvent times are 10 times and 8 times respectively), 1 hour each time;

[0038] Combine the extracts, centrifuge, and concentrate under reduced pressure at 60°C to about 20L;

[0039] The concentrated solution is passed through an ultrafiltration membrane, the ultrafiltrate is added with hydrochloric acid to adjust the pH to 3.0, and centrifuged to obtain an acidified solution;

[0040] Take 2L of the acidification solution, put it on a 001×8 resin column with a column volume of 1L, wash it with water for 3 times the column volume, and then use 3 times the column volume concentration to elute with 1.0% ammonia water, the flow rate...

Embodiment 2

[0045] Get 3L of the ammonia eluent in Example 1, and adjust to neutrality with hydrochloric acid;

[0046] The HP20 macroporous resin column with a column volume of 1L was washed with water for 2 times the column volume, and then gradient eluted with an ethanol solution with a concentration of 2 times the column volume of 10-70%, and the flow rate was 1 times the column volume / h, and collected in steps eluent;

[0047] Combine eluents with an ethanol concentration of 20%-40%, concentrate under reduced pressure (55°C-60°C), and dry in vacuum to obtain a crude product with a content of 52.8%, with a total conversion rate of 84.2% and a yield of 0.43% ;

[0048] Take 8.0g of the obtained crude product, dissolve it in 200ml of absolute ethanol, pass it through a basic alumina adsorption column, collect the effluent, concentrate under reduced pressure under vacuum (55°C-60°C) to an appropriate volume, crystallize at room temperature, and recrystallize 1-2 times , the 1-DNJ refin...

Embodiment 3

[0050] Get 3L of the ammonia eluent in Example 1, and adjust to neutrality with hydrochloric acid;

[0051]The CAD-40 macroporous resin column with a column volume of 1L was washed with water for 2 times the column volume, and then gradient eluted with an ethanol solution with a concentration of 10-70% for 2 times the column volume, and the flow rate was 1 times the column volume / h. Step to collect the eluate;

[0052] Combine eluents with an ethanol concentration of 20%-40%, concentrate under reduced pressure (55°C-60°C), and dry in vacuum to obtain a crude product with a content of 54.1%, with a total conversion rate of 86.1% and a yield of 0.42% ;

[0053] Take 8.0g of the obtained crude product, dissolve it in 200ml of absolute ethanol, pass it through a basic alumina adsorption column, collect the effluent, concentrate under reduced pressure under vacuum (55°C-60°C) to an appropriate volume, crystallize at room temperature, and recrystallize 1-2 times , to obtain a refi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com