Constant speed mechanical water sampling device and sampling method

A technology of sampling device and mechanical water, which is applied in sampling device, material absorption and weighing, etc., can solve the problems of inability to accurately capture the carrying amount of mechanical water, inability to achieve isokinetic sampling, inability to meet the requirements of content testing, etc. The effect of accurate measurement of mechanical water content blank, simple and feasible operation method, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

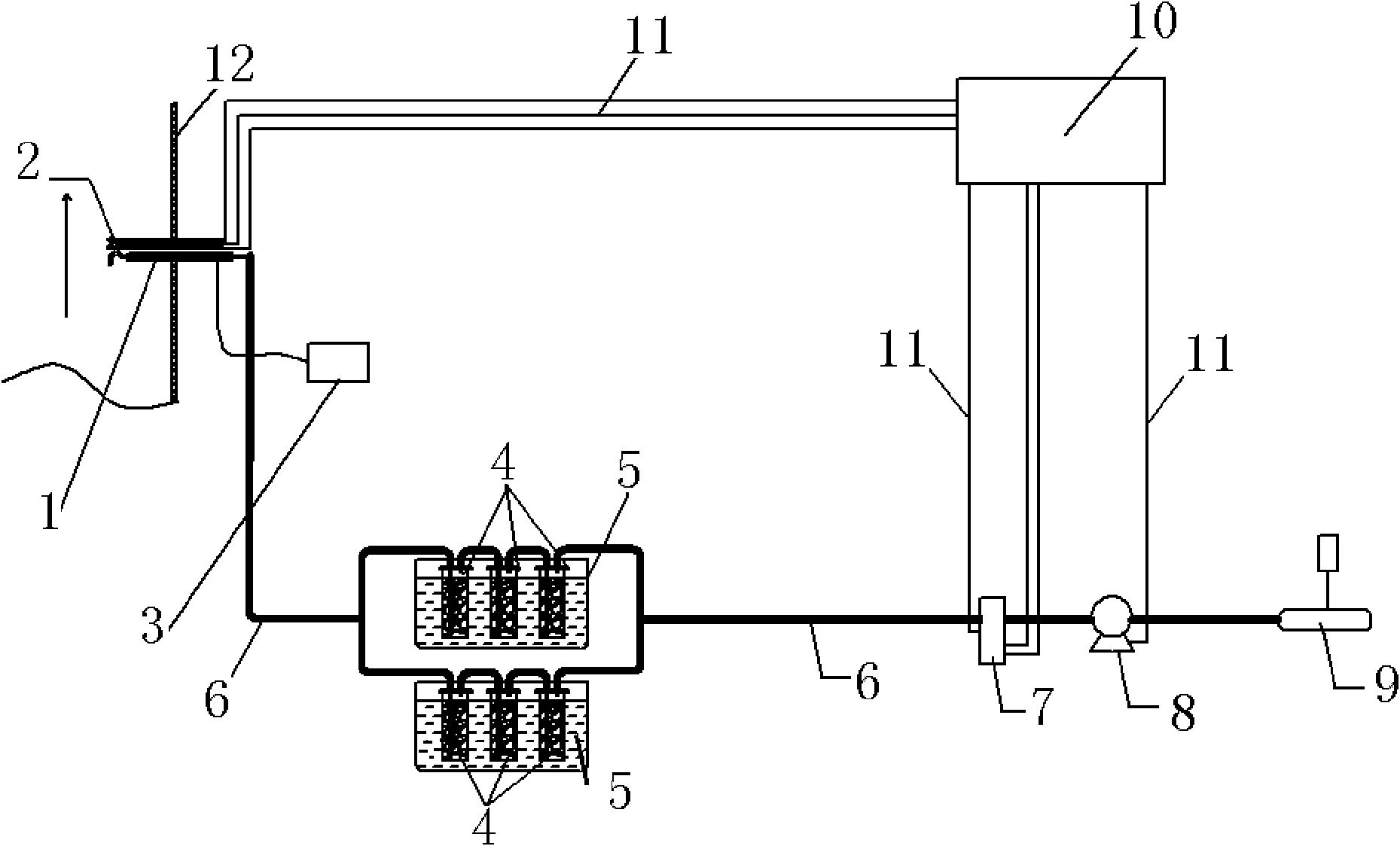

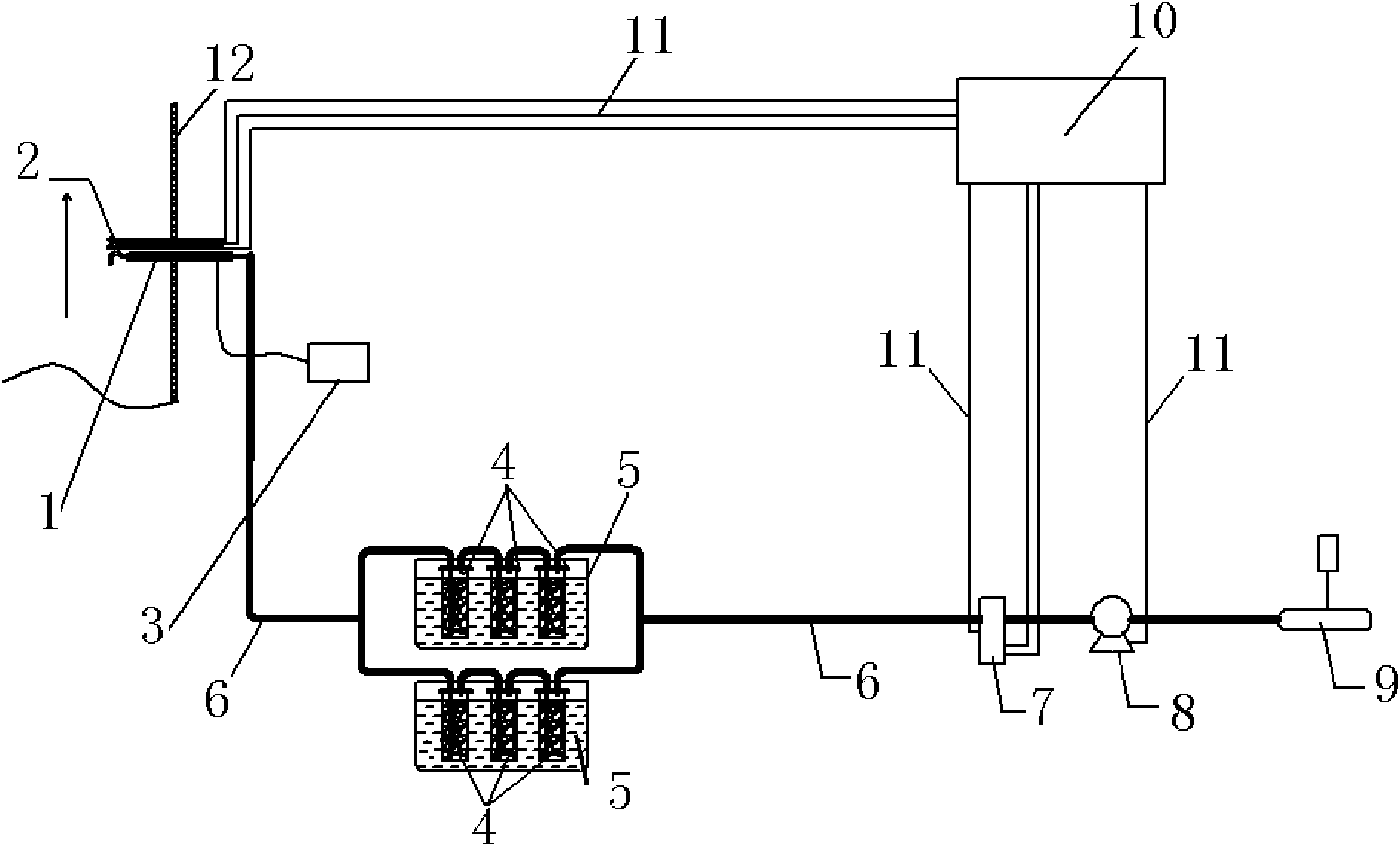

[0053] Utilize the sampling method of described isokinetic mechanical water sampling device, comprise the following steps:

[0054] (1) Install a standard caliber sampling nozzle on the electric heating sampling gun 1, and arrange it with the S-type pitot tube and thermocouple 2 at the cross-section of the flue gas in the direction of the flue gas flow; The gun 1 and the smoke hose 6 connected with the flow meter 7 are weighed;

[0055] (2) According to the requirements of the technological process, the constant velocity sampling mechanical water measuring device is connected, and the temperature of the electric heating controller 3 is controlled to be 75°C, and the temperature of the cooling water tank is 3°C;

[0056](3) Input measured flue gas density 0.50, sampling nozzle diameter, parameters such as atmospheric pressure about 101.25kpa in single-chip microcomputer 10; , control and adjust the speed and flow rate of the air pump 8 to ensure that the intake flow rate of th...

Embodiment 2

[0059] Utilize the sampling method of described isokinetic mechanical water sampling device, comprise the following steps:

[0060] (1) Install a standard caliber sampling nozzle on the electric heating sampling gun 1, and arrange it with the S-type pitot tube and thermocouple 2 at the cross-section of the flue gas in the direction of the flue gas flow; The gun 1 and the smoke hose 6 connected with the flow meter 7 are weighed;

[0061] (2) Connect the constant velocity sampling mechanical water measuring device according to the requirements of the technological process, and control the temperature of the electric heating controller 3 to be 85° C., and the temperature of the cooling water tank to be 7° C.;

[0062] (3) Input measured flue gas density 1.50kg / Nm in the single-chip microcomputer 10, sampling nozzle diameter, parameters such as atmospheric pressure about 101.25kpa; Pressure and other data, control and adjust the speed and flow of the air pump 8, to ensure that th...

Embodiment 3

[0065] Utilize the sampling method of described isokinetic mechanical water sampling device, comprise the following steps:

[0066] (1) Install a standard caliber sampling nozzle on the electric heating sampling gun 1, and arrange it with the S-type pitot tube and thermocouple 2 at the cross-section of the flue gas in the direction of the flue gas flow; The gun 1 and the smoke hose 6 connected with the flow meter 7 are weighed;

[0067] (2) Connect the constant velocity sampling mechanical water measuring device according to the requirements of the technological process, and control the temperature of the electric heating controller 3 to be 80°C, and the temperature of the cooling water tank to be 5°C;

[0068] (3) Input measured flue gas density 1.0kg / Nm in the single-chip microcomputer 10, sampling nozzle diameter, parameters such as atmospheric pressure about 101.25kpa; Pressure and other data, control and adjust the speed and flow of the air pump 8, to ensure that the int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Caliber | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com