Ink composition

An ink composition and the technology of the composition are applied in the directions of inks, household appliances, luminescent materials, etc., which can solve the problems of impracticality, low luminous brightness, and no records, and achieve the effects of improving power generation efficiency and good dispersion stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0085] Hereinafter, the present invention will be described in more detail using examples and the like, but the scope of the present invention is not limited by these examples. In addition, in Examples, unless otherwise specified, "part" and "%" represent a mass basis.

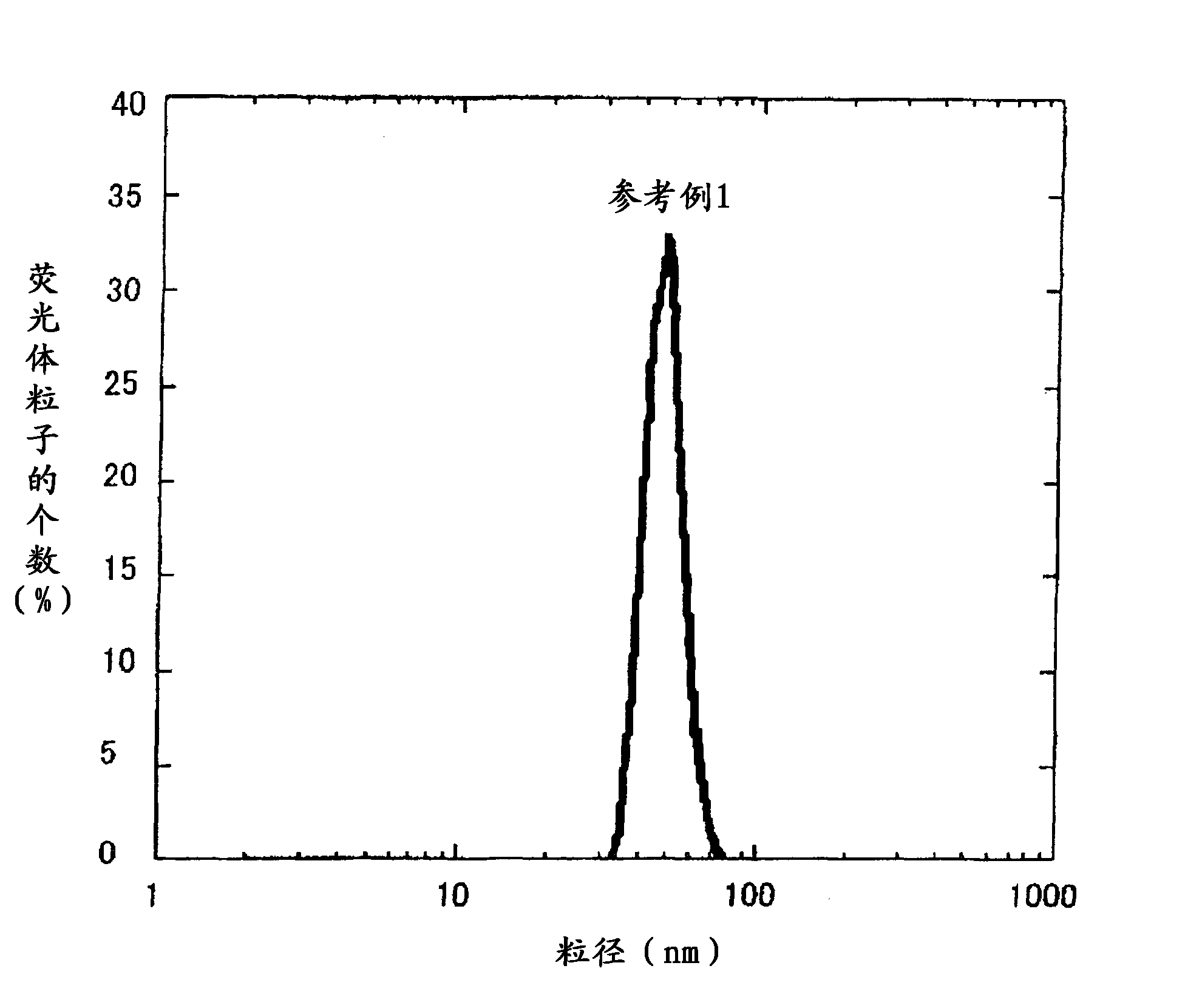

reference example 1

[0087] In a 200 ml 4-necked flask, a condenser as a reflux device, a thermometer, and a stirring device were installed, and the flask was placed in a water bath. Add 40.0ml of water, 1.00g (2.6mmol) of yttrium nitrate hexahydrate, 0.09g (0.2mmol) of europium nitrate hexahydrate, and 0.62g of trisodium citrate dihydrate into the flask, and stir at 60°C for 2 hours to prepare Solution 1.

[0088] In addition, measure 40.0 ml of water whose pH was adjusted to 12.5 with sodium hydroxide, add 0.55 g (3.0 mmol) of sodium orthovanadate to it, and dissolve it to prepare solution 2, and add solution 2 dropwise to the solution containing 1 in the above-mentioned 3-neck flask.

[0089]After completion of the dropwise addition, stirring was performed at 60° C. for 3 hours. The pH immediately after the dropwise addition was 8.5. Then, it was cooled to room temperature to obtain a slightly yellowish white suspension in water. The dispersion liquid obtained by processing with an ultrason...

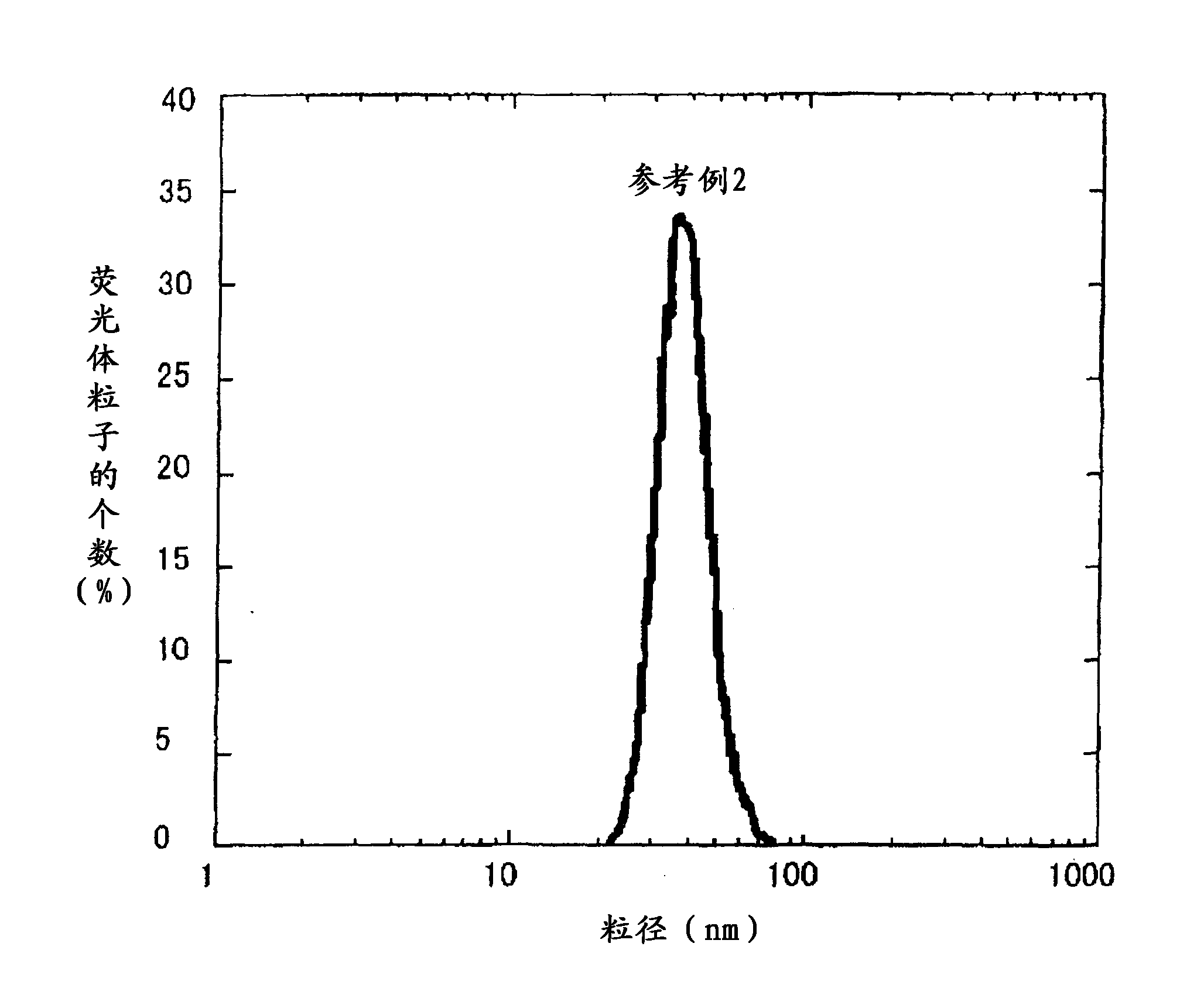

reference example 2

[0093] In a 200 ml 4-necked flask, a condenser as a reflux device, a thermometer, and a stirring device were installed, and the flask was placed in a water bath. 40.0ml of water, 0.10g (0.3mmol) of yttrium nitrate hexahydrate, and 0.05g (0.1mmol) of terbium nitrate hexahydrate were added to the flask, and stirred at 80°C for 1 hour, then 0.19g of oxalic acid was added, and the reaction was carried out at 80°C. After stirring for 2 hours, solution 1 was prepared.

[0094] In addition, 40.0 ml of water whose pH was adjusted to 12.5 with sodium hydroxide was measured with a 100 ml measuring cup, 0.06 g (0.3 mmol) of sodium orthovanadate was added thereto, and dissolved to prepare solution 2, and the obtained solution 2 Add dropwise to the 3-necked flask containing solution 1.

[0095] After completion of the dropwise addition, stirring was performed at 80° C. for 3 hours. The pH immediately after the dropwise addition was 8.2. Then, it was cooled to room temperature to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com