Fluidized bed bioreactor

A technology of bioreactor and fluidized bed, which is applied in the direction of bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biochemical instrument, etc., and can solve the problem of cell and carrier flushing out, limited amplification effect, etc. problem, to achieve the effect of good amplification potential, utilization of tank volume, and convenient extraction and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

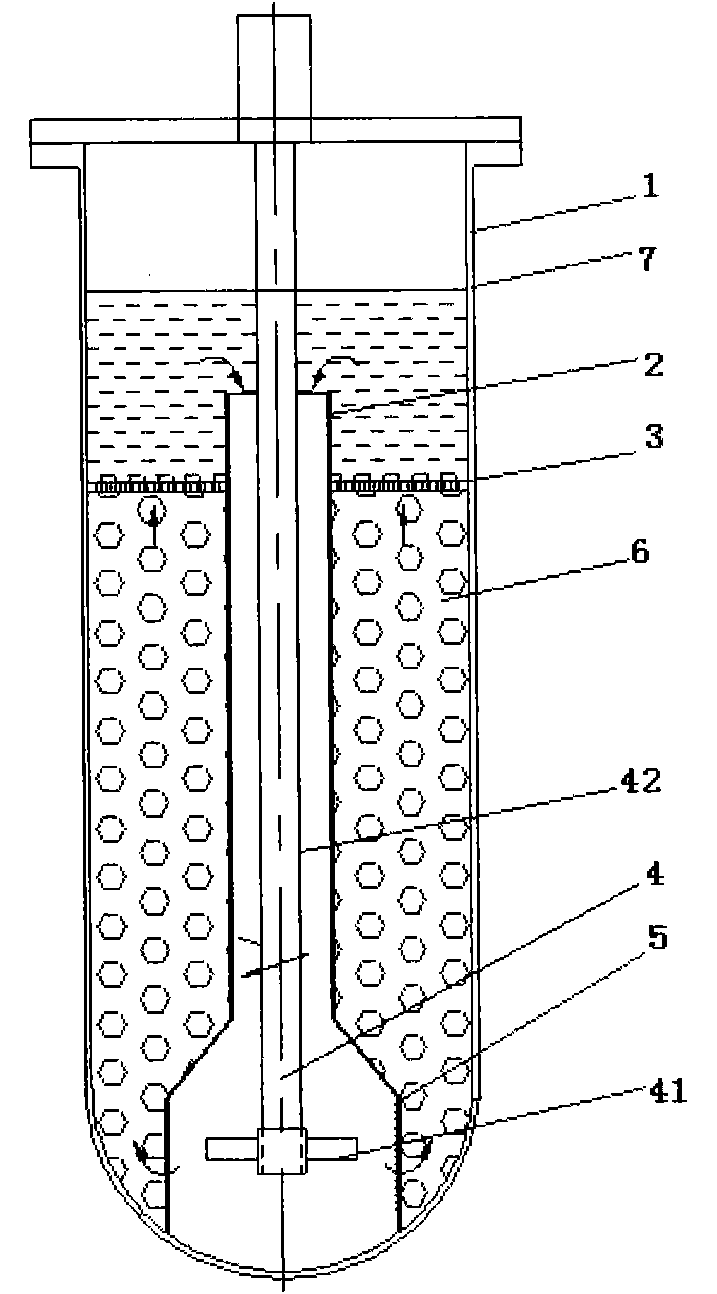

[0032] Embodiment 1: Utilize the fluidized bed bioreactor of the present invention to carry out Vero cell culture

[0033] In the fluidized bed bioreactor (Shanghai Ritai 10L type), add sheet polyester carrier, add phosphate buffer (pH7.2) at the same time, sterilize under high pressure at 123 ℃ for 60 minutes, and naturally cool overnight. On the second day, the phosphate buffer solution in the tank was drained, and the DMEM medium containing 10% fetal bovine serum was added to inoculate Vero cells. After inoculation, the cell density in the tank reached 5x10 5 / ml to start cell culture.

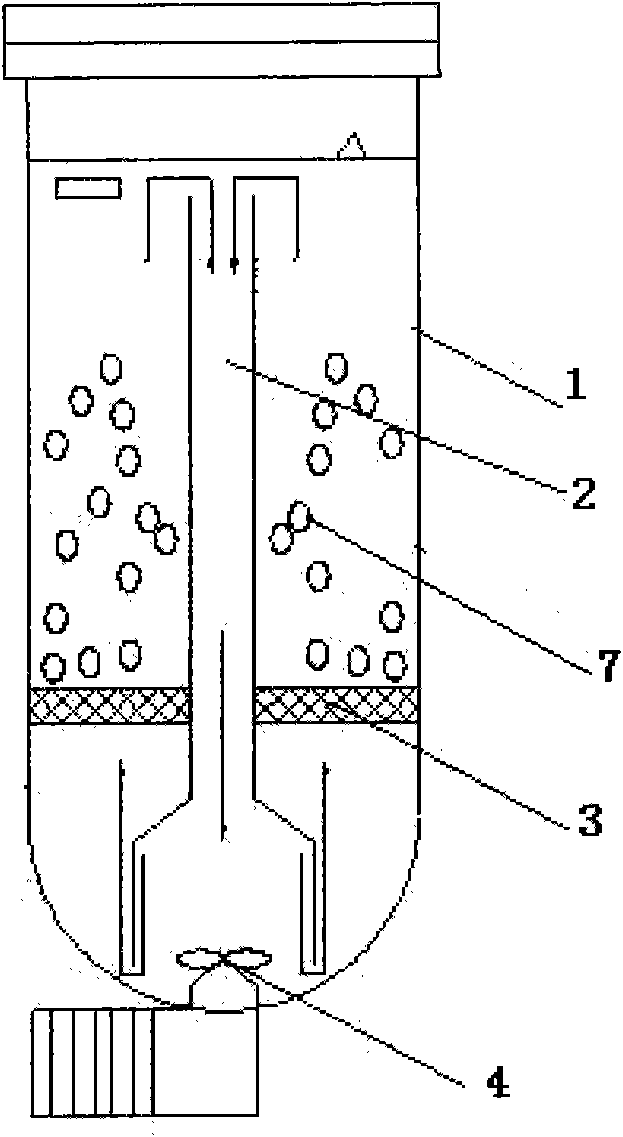

[0034] Set the reactor cell culture conditions as temperature 37°C, pH 7.2, DO 50% for cell culture. Start the stirring device and set the speed at 80 rpm. At this speed, the speed of the culture solution is lower than the flushing point, and the carrier settles down, forming a culture method similar to fixed bed culture. The working state diagram is shown in image 3 , the carrier is rel...

Embodiment 2

[0038] Embodiment 2: Utilize the fluidized bed bioreactor of the present invention to carry out the mass culture of Chinese hamster ovary cell (CHO cell)

[0039] Add 300 grams of domestic flake polyester carrier and 8 L of phosphate buffer (pH 7.2) into a 10 L fluidized bed bioreactor, autoclave at 123 °C for 60 minutes, and cool overnight naturally. On the second day, the phosphate buffer solution in the tank was drained, and DMEM medium containing 10% fetal bovine serum was added to inoculate CHO cells. After inoculation, the cell density in the tank reached 5x10 5 / ml to start cell culture.

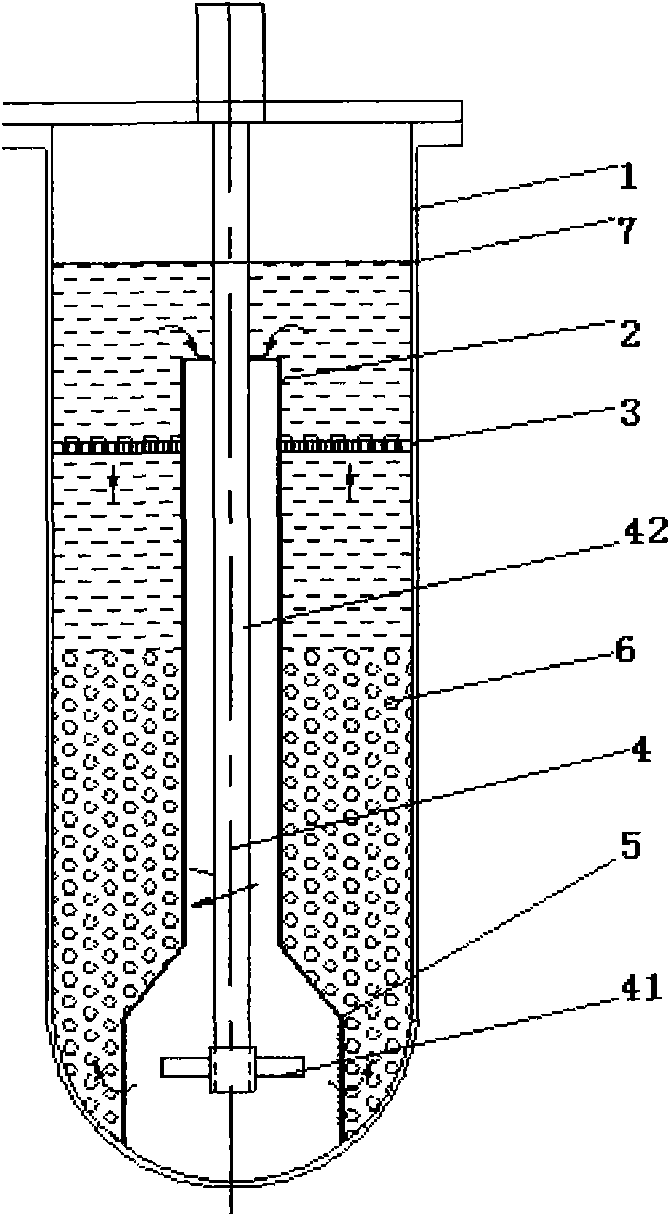

[0040] Set the reactor cell culture conditions as temperature 37°C, pH 7.2, DO 50% for cell culture. Start the stirring device and set the speed at 80 rpm. At this speed, the speed of the culture solution is lower than the flushing point, forming a culture method similar to a fixed bed, but a slight shaking of the carrier can be observed, which helps Homogenize the culture medium an...

Embodiment 3

[0044] Embodiment 3: Utilize the fluidized bed bioreactor of the present invention to carry out the mass culture of 293 cells

[0045] Add 300 grams of domestic flake polyester carrier and 8 L of phosphate buffer (pH 7.2) into a 10 L fluidized bed bioreactor, autoclave at 123 °C for 60 minutes, and cool overnight naturally. On the second day, the phosphate buffer solution in the tank was drained, and high-sugar DMEM medium was added to inoculate 293 cells. After inoculation, the cell density in the tank reached 5x10 5 / ml to start cell culture.

[0046] Set the cell culture conditions of the reactor as temperature 37°C, pH 7.2, DO 50% for cell culture, start the stirring device, and set the speed at 80 rpm. At this speed, the fluid velocity is lower than the flushing point, forming a similar The culture method is a fixed bed, but a slight shaking of the carrier can be observed, which helps to uniform the culture solution, and culture in this state for 1 hour.

[0047] Change...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com