Method for preparing monocrystalline silicon suede

A single crystal silicon wafer and silicon fleece technology is applied in the field of preparing single crystal silicon textured surface, which can solve the problems of poor appearance of cells, influence on luminous efficiency of solar cells, uneven textured surface, etc., so as to shorten the texturing reaction time and improve the Conversion efficiency, the effect of improving light absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

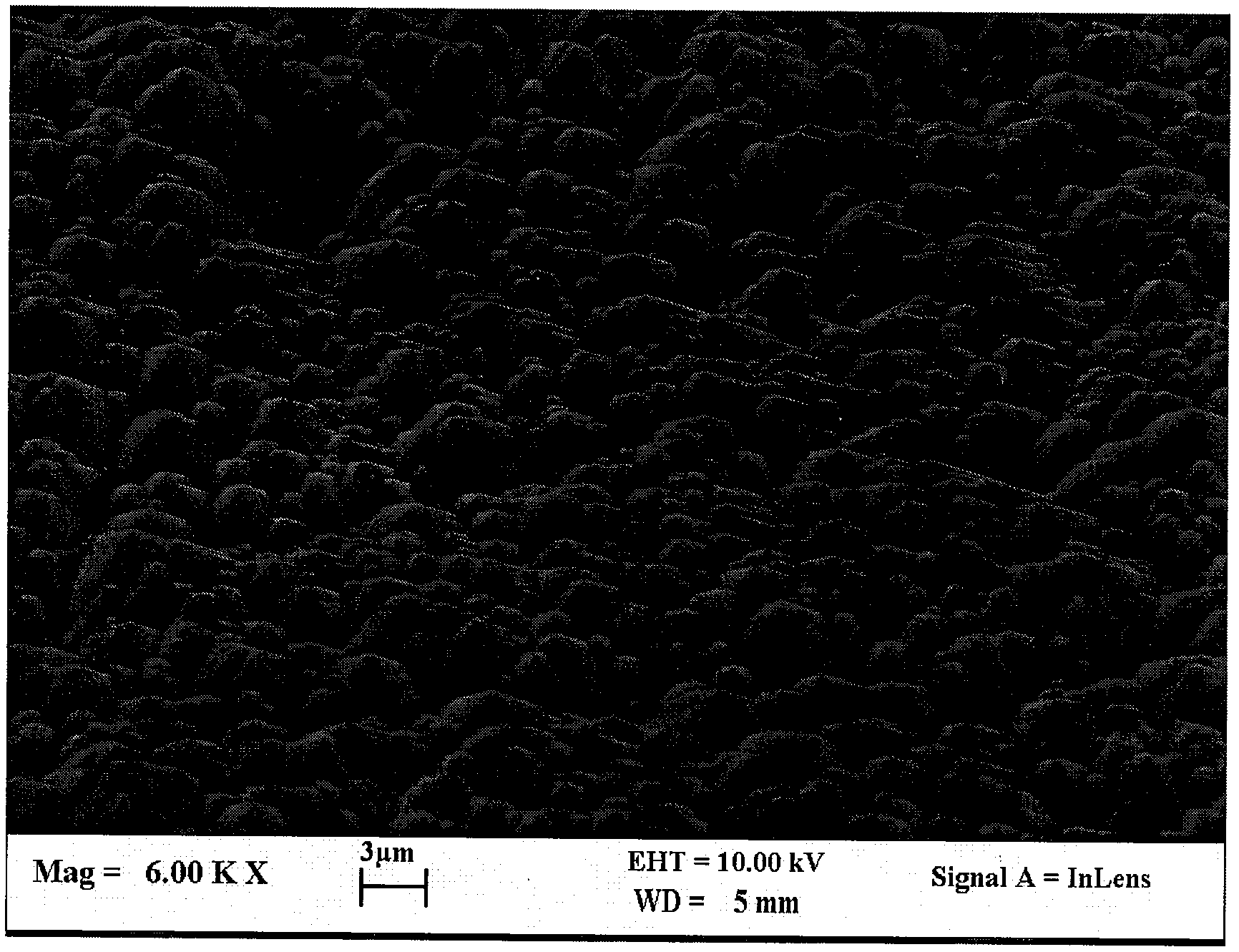

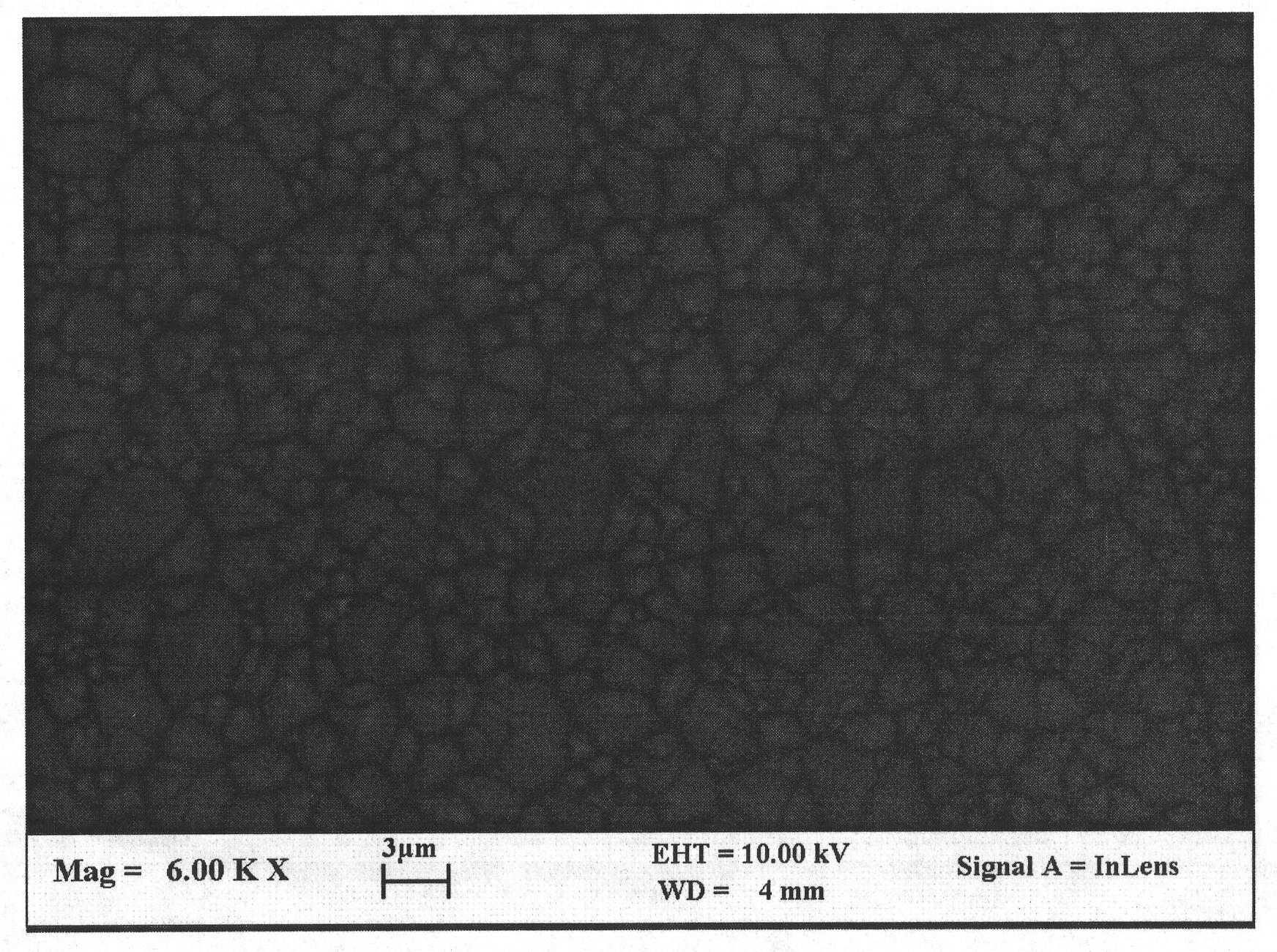

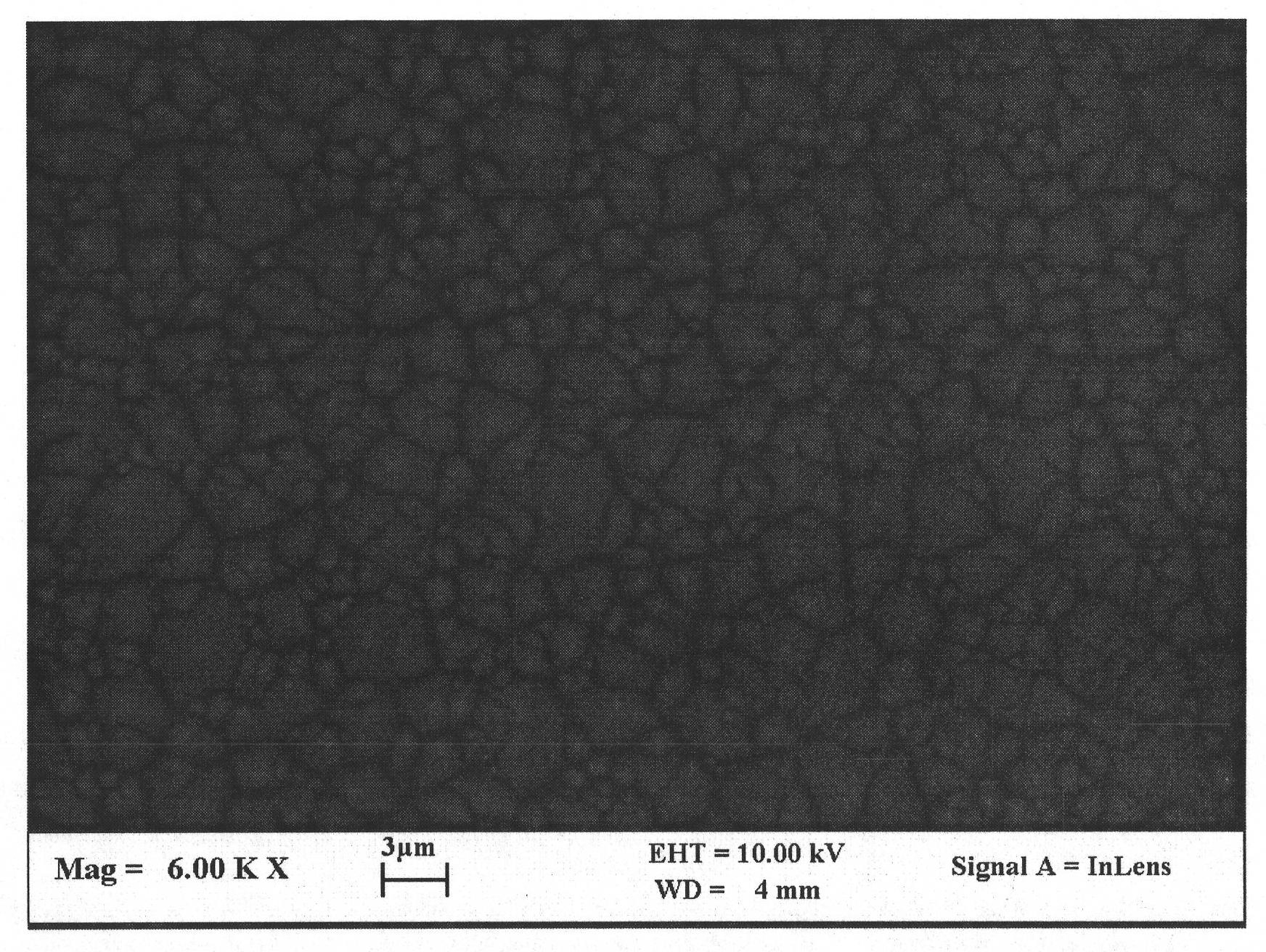

Image

Examples

Embodiment 1

[0013] Embodiment 1: This embodiment comprises the following steps:

[0014] 1) Preparation of coarse throwing liquid: directly use a sodium hydroxide solution with a concentration of 45%; use 45% sodium hydroxide and deionized water to prepare a rough throwing liquid with a concentration of 0.05% in a constant temperature bath at 75°C;

[0015] 2) Preparation of alkaline corrosion solution: raw material ratio, calculated by weight percentage, 0.5% analytically pure sodium hydroxide, 1% analytically pure isopropanol, 0.1% analytically pure sodium silicate and 98.4% deionized water It is 45% sodium hydroxide solution that the analysis pure sodium hydroxide of described amount and deionized water are made into concentration, then in the constant temperature tank of 75 ℃, the 45% sodium hydroxide solution of making and described A certain amount of analytical pure isopropanol, analytical pure sodium silicate and the remaining deionized water are mixed to prepare an alkaline corro...

Embodiment 2

[0017] Embodiment 2: This embodiment comprises the following steps:

[0018] 1) Preparation of coarse throwing liquid: use analytical pure potassium hydroxide and deionized water to prepare a potassium hydroxide solution with a concentration of 45%, and configure it with 45% potassium hydroxide solution and deionized water in a constant temperature tank at 80°C Coarse throwing liquid with a concentration of 0.1%;

[0019] 2) Preparation of alkaline corrosion solution: raw material ratio, calculated by weight percentage, 1% analytical pure potassium hydroxide, 2% analytical pure isopropanol, 0.5% analytical pure sodium silicate and 96.5% deionized water The analytical pure potassium hydroxide and deionized water of said amount are made into a concentration of 45% potassium hydroxide solution, and then in a constant temperature tank of 75°C to 85°C, the prepared 45% potassium hydroxide solution Mix with the amount of analytical pure isopropanol, analytical pure sodium silicate ...

Embodiment 3

[0021] Embodiment 3: this embodiment comprises the following steps:

[0022] 1) The preparation of coarse throwing liquid: use analytical pure sodium carbonate and deionized water to prepare a concentration of 45% sodium carbonate solution, and use 45% sodium carbonate solution and deionized water to configure a concentration of 0.2 in a constant temperature tank at 85°C. % of rough liquid;

[0023] 2) Preparation of alkaline corrosion solution: raw material ratio, calculated by weight percentage, 2% analytically pure sodium carbonate, 3% analytically pure isopropanol, 0.4% analytically pure sodium silicate and 94.6% deionized water; The analytical pure sodium carbonate of described amount and deionized water are made into the sodium carbonate solution that concentration is 45%, then in the constant temperature tank of 85 ℃, the sodium carbonate solution of 45% that makes and the analytical pure sodium carbonate of described amount Isopropanol, analytical pure sodium silicate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com