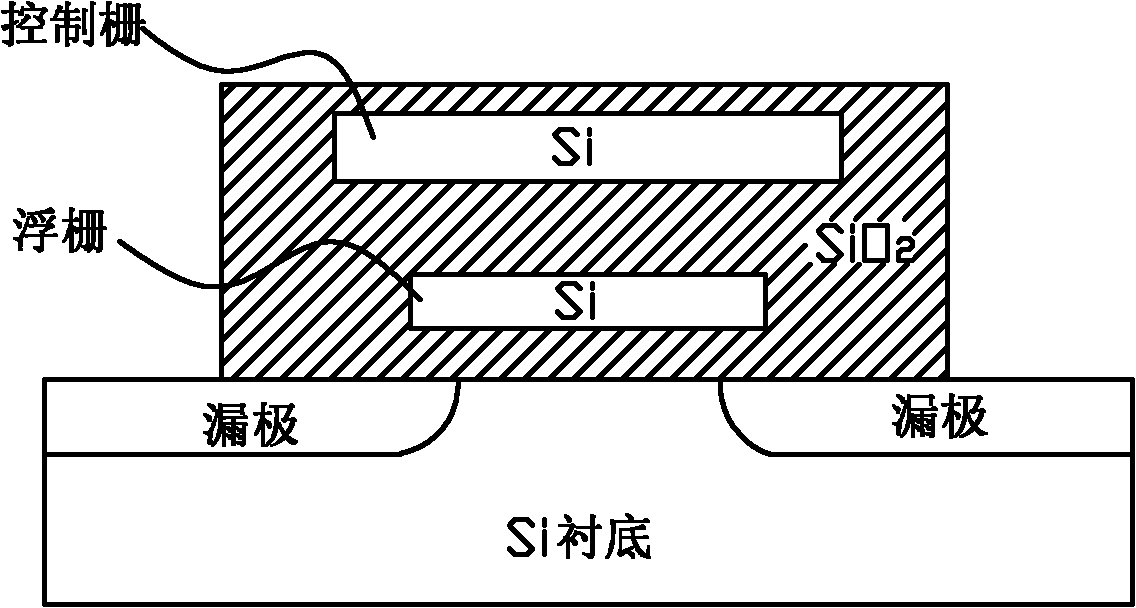

Organic floating gate field effect transistor and preparation method thereof

A technology of field-effect transistors and transistors, applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve problems that cannot be solved well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

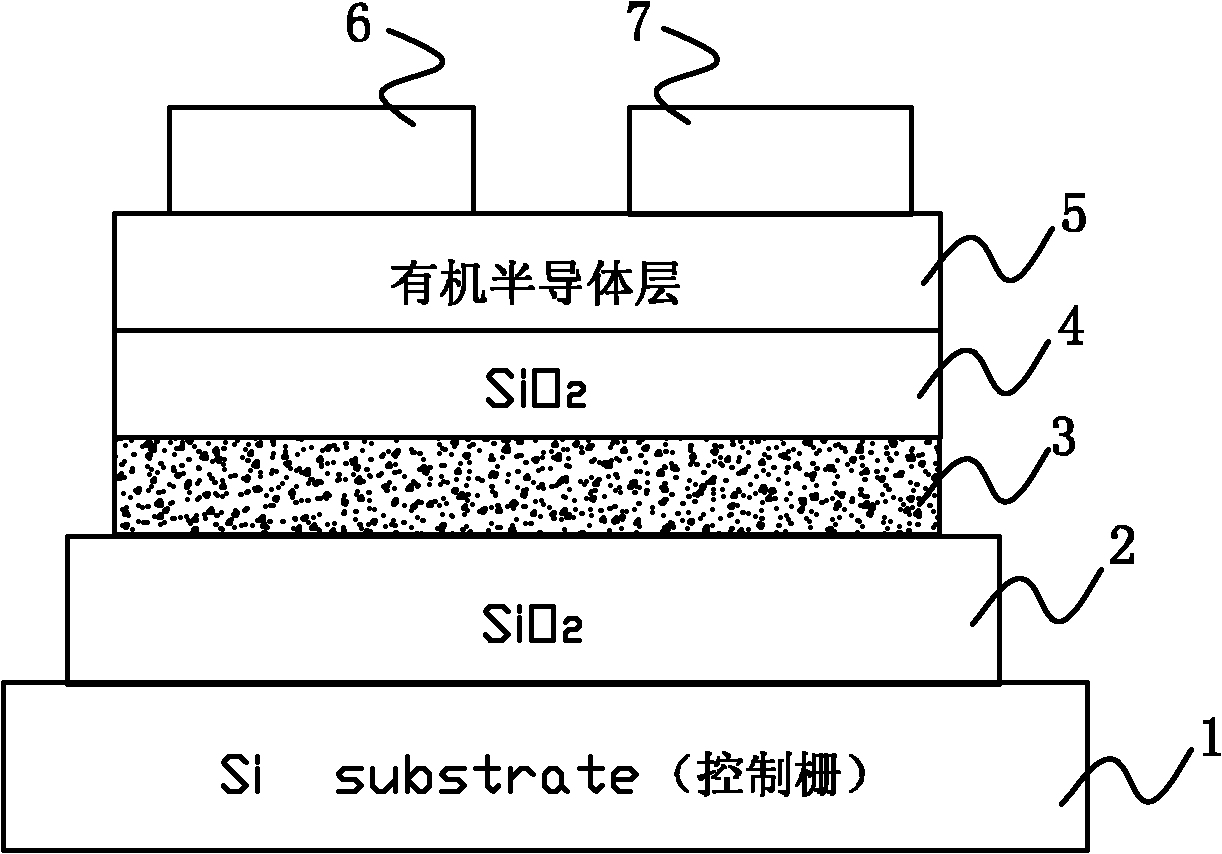

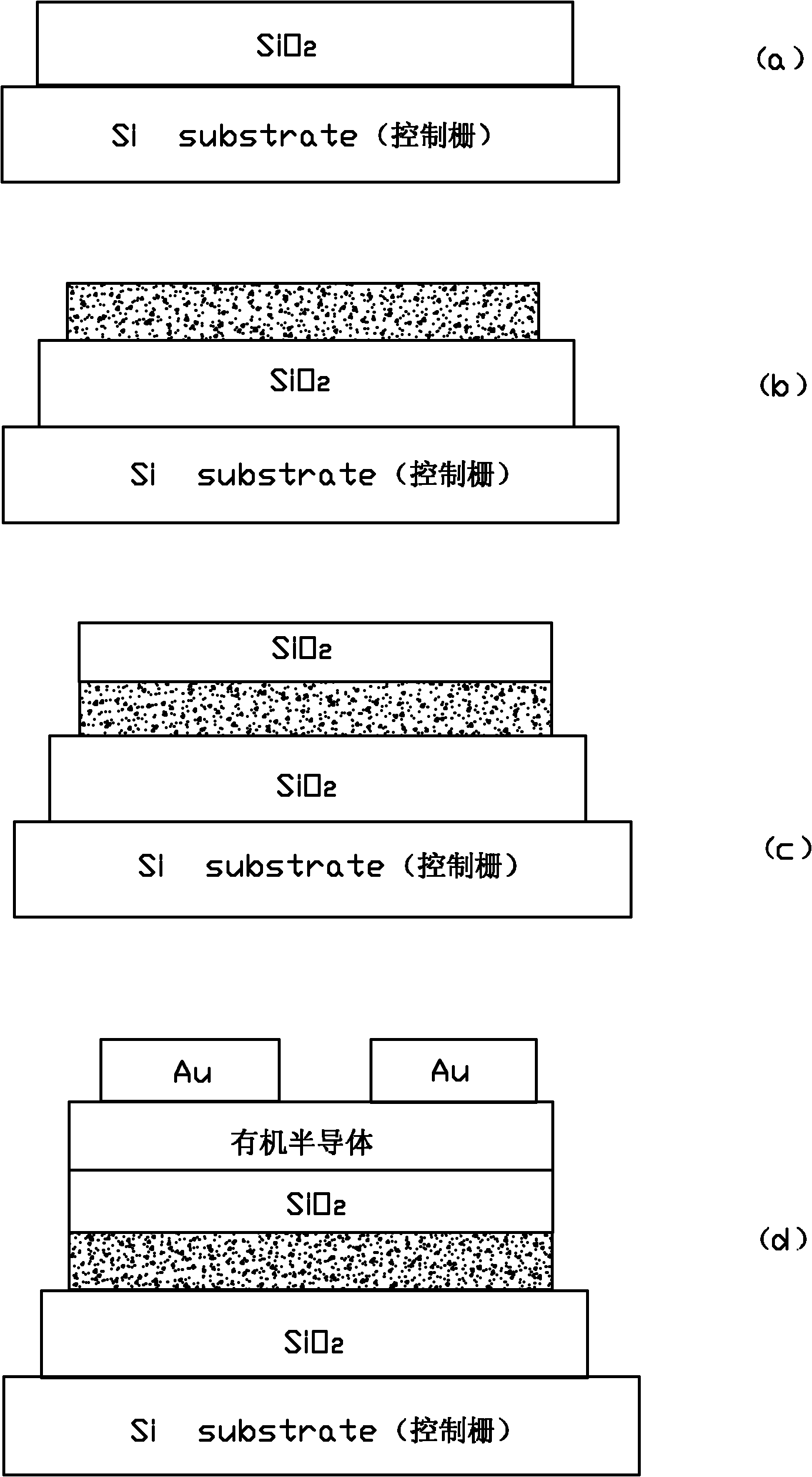

[0025] Such as image 3 The method for preparing the organic floating gate field effect transistor includes the following steps:

[0026] ①. On the silicon substrate 1, a layer of silicon dioxide film is grown as the insulating layer I 2 by the method of thermal oxidation; see the attached image 3 .(a)

[0027] 2. Prepare a low-resistance silicon film as the floating gate 3 on the silicon dioxide film layer, i.e. the insulating layer 1 , by magnetron sputtering; image 3 .(b)

[0028] ③. On the 3rd layer of the floating gate, grow a thin layer of silicon dioxide as the insulating layer II4 by means of thermal oxidation; see attached image 3 .(c)

[0029] ④, then vacuum thermally evaporate a layer of organic semiconductor thin film material on the insulating layer II4 to form the semiconductor active layer 5;

[0030] 5. Vacuum heat evaporation of one layer of gold thin film layer on the semiconductor active layer 5 is used as the electrode material of the device;

[00...

Embodiment

[0034] Such as image 3 As shown, a layer of silicon dioxide insulating layer I2 is prepared on the polysilicon substrate 1 by thermal oxidation (dry oxygen oxidation method), the conditions are: the oxidation temperature is 1200 degrees Celsius, and the dry oxygen oxidation time is about 1 hour, and then use Prepare a layer of silicon film (floating gate 3) on the silicon dioxide insulating layer by magnetron sputtering (sputtering conditions are sputtering power 250W, background vacuum degree 1.5×10 -4 Pa, Ar gas pressure 1Pa. ), the thickness of the silicon film is about 20nm. Then prepare a layer of silicon dioxide insulating layer II4 by thermal oxidation (dry oxygen), the conditions are: the preparation environment is 1200 degrees Celsius, dry oxygen for 5 minutes, and the thickness of the obtained silicon dioxide is about ten nanometers. Then adopt the method for vacuum thermal evaporation to prepare organic semiconductor material (form semiconductor active layer 5), ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Channel length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com