Composite pipe blank casting device and continuous casting method

A tube billet and multi-layer technology, which is applied in the field of multi-layer billet casting equipment and continuous casting, can solve the problems of different components and properties of the inner and outer layers, weak combination of composite interface, low production efficiency, etc., and achieve easy large-scale continuous casting Production, suppression of segregation of the melt, and favorable effects in forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Step 1: Melting and heat preservation of alloy billet

[0043]3003 aluminum alloy and 4004 aluminum alloy are respectively used as the inner metal liquid 11 and the outer metal liquid 12, and they are respectively heated to 730°C and 700°C, refined and degassed, then kept warm for use.

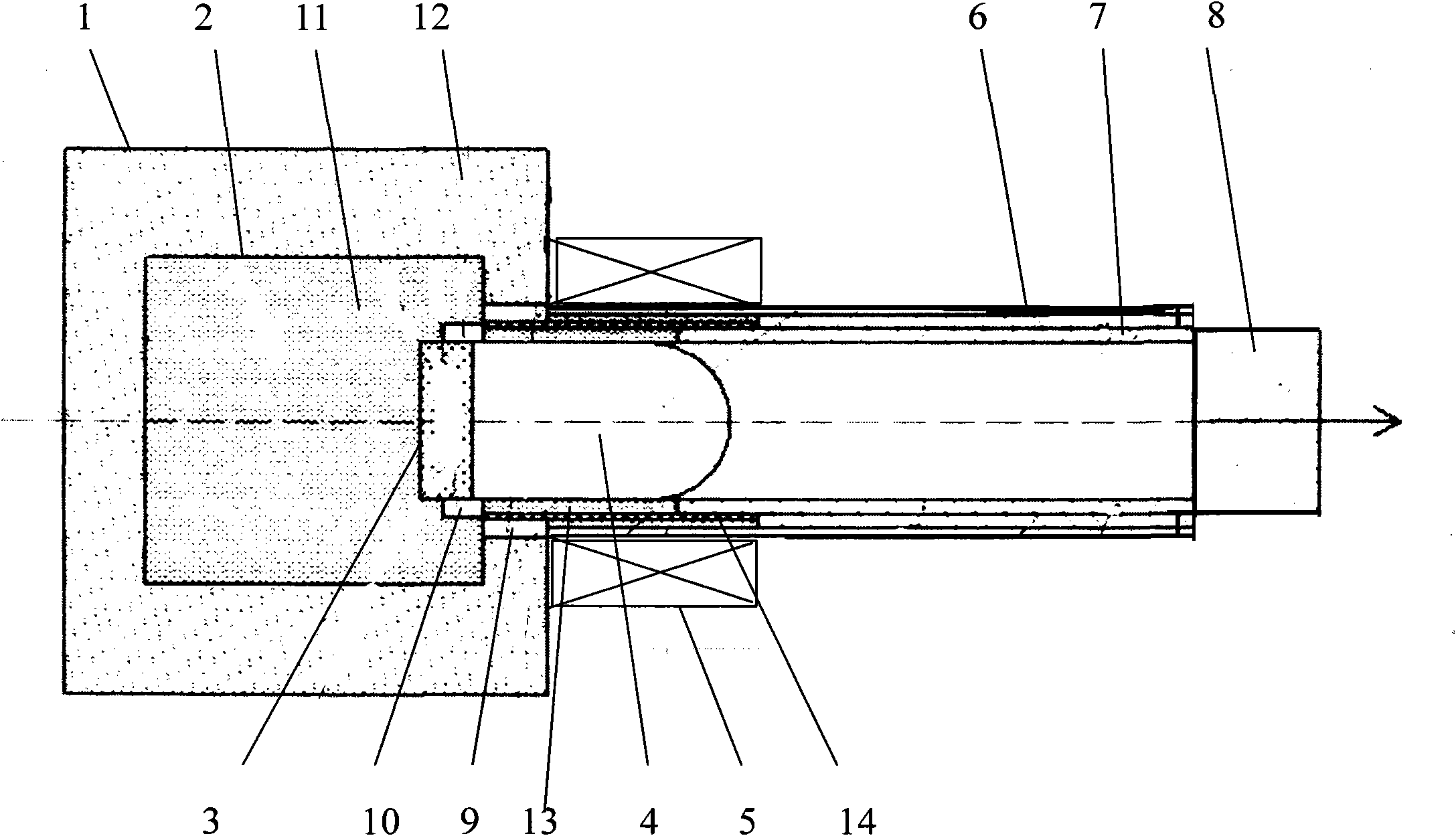

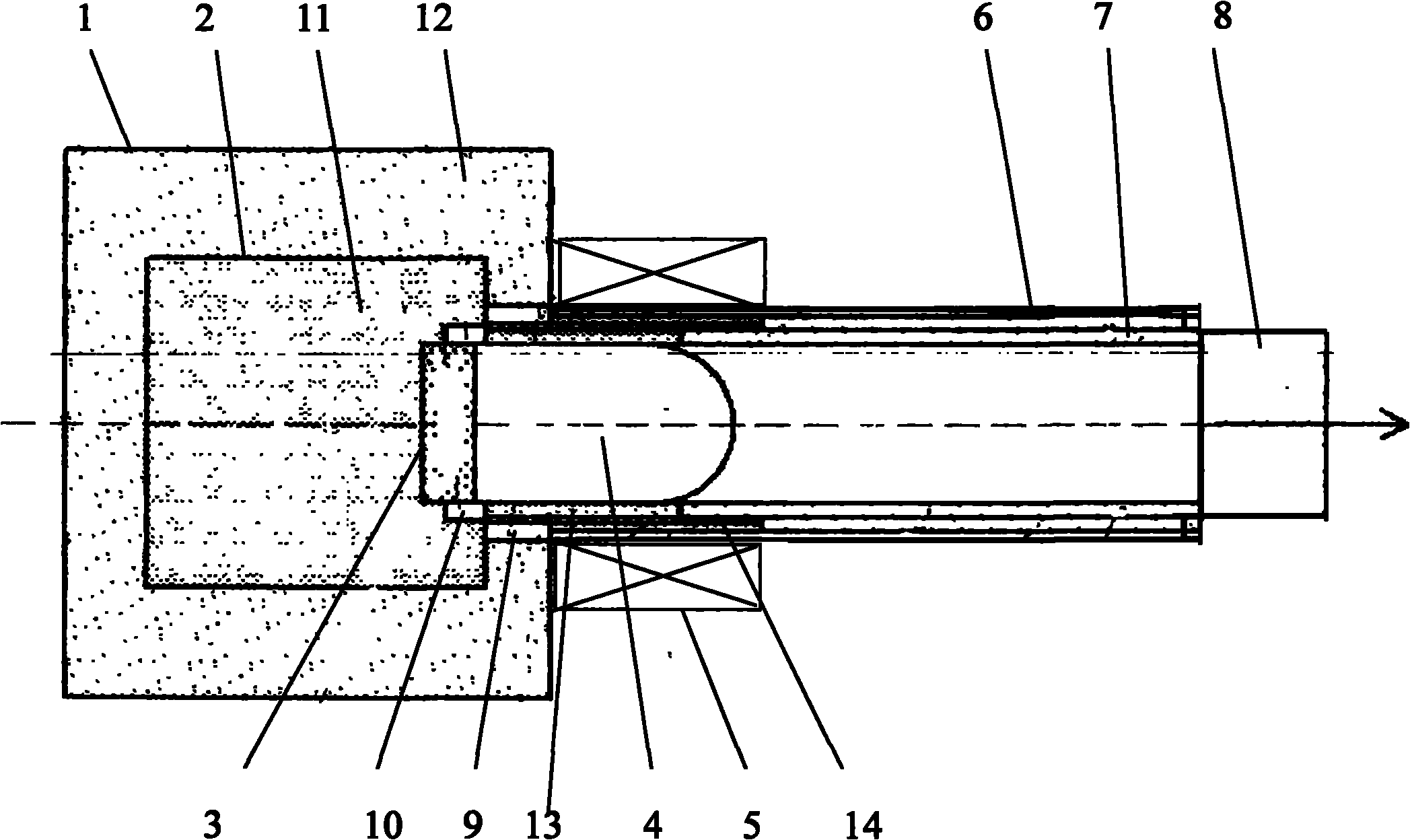

[0044] Step 2: Continuous casting of clad shell

[0045] Put the traction pipe 7 in front of the crystallizer 3, adjust it to maintain a horizontal position, check the cooling water system and ensure that it is in normal working condition, and then pass the pre-insulated inner layer metal liquid 11 through the inner control valve 10 into the crystallizer In the device 3, the electromagnetic generating device 5 is turned on, and the magnetic field mode is a DC magnetic field to generate a 200mT DC magnetic field. The tractor 8 pulls the billet at a speed of 0.5m / min through the traction tube 7. After the inner layer of molten metal is solidified, the outer layer is turned on. The contro...

Embodiment 2

[0052] Step 1: Melting and heat preservation of alloy billet

[0053] 3003 aluminum alloy and 4045 aluminum alloy are respectively used as the inner metal liquid 11 and the outer metal liquid 12, and they are respectively heated to 730°C and 715°C, refined and degassed, then kept warm for use.

[0054] Step 2: Continuous casting of clad shell

[0055] Put the traction pipe 7 in front of the crystallizer 3, adjust it to maintain a horizontal position, check the cooling water system and ensure that it is in normal working condition, and then pass the pre-insulated inner layer metal liquid 11 through the inner control valve 10 into the crystallizer In the device 3, the electromagnetic generating device 5 is turned on, and the magnetic field mode is a DC magnetic field to generate a DC magnetic field of 150mT. The tractor 8 pulls the blank at a speed of 0.8m / min through the traction tube 7. After the inner layer of molten metal is solidified, the outer layer is turned on. The con...

Embodiment 3

[0061] Step 1: Melting and heat preservation of alloy billet

[0062] The 3103 aluminum alloy and the 4343 aluminum alloy are respectively used as the inner metal liquid 11 and the outer metal liquid 12, and they are respectively heated to 725°C and 700°C, refined and degassed, then kept warm for use.

[0063] Step 2: Continuous casting of clad shell

[0064] Put the traction pipe 7 in front of the crystallizer 3, adjust it to maintain a horizontal position, check the cooling water system and ensure that it is in normal working condition, and then pass the pre-insulated inner layer metal liquid 11 through the inner control valve 10 into the crystallizer In the device 3, the electromagnetic generating device 5 is turned on, and the magnetic field mode is a DC magnetic field, which generates a 300mT DC magnetic field. The tractor 8 pulls the blank at a speed of 1m / min through the traction tube 7. After the inner metal is solidified, open the outer control valve 9. Pouring the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com