Method for concentrating and purifying dilute acid by using waste heat of smelting flue gas and device thereof

A smelting flue gas, concentration and purification technology, applied in chemical instruments and methods, sulfur trioxide/sulfuric acid, waste heat treatment, etc., can solve the problems of sulfuric acid not being effectively used, increasing the cost of sewage acid treatment, waste of sulfur resources, etc. Achieve the effect of saving the cost of sewage acid treatment, reducing working pressure and reducing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

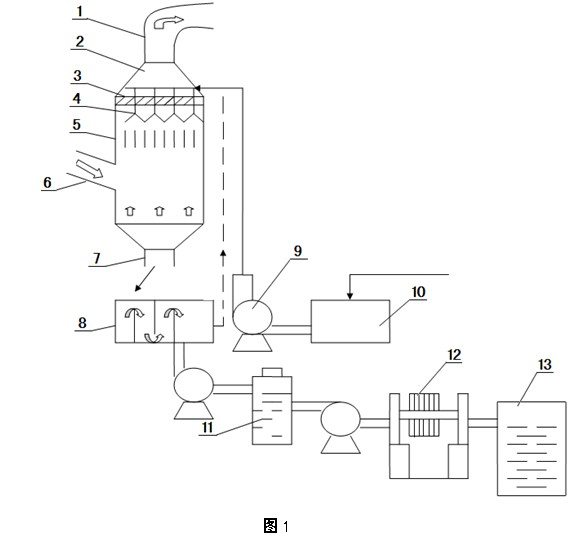

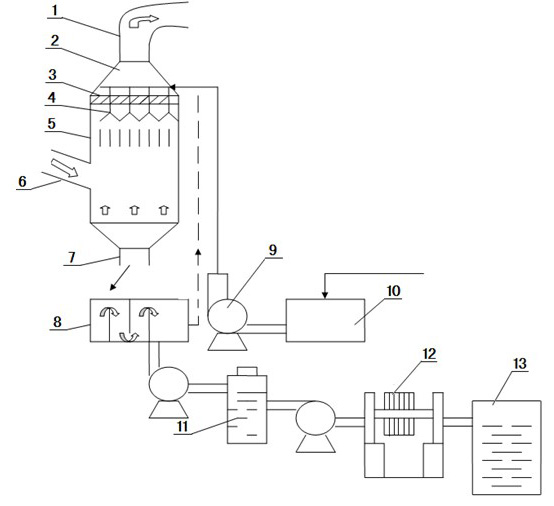

[0016] The flue gas coming out from the high-temperature fan of the electric dust collection reaches the spray concentration tower 2, and contacts with the dilute acid generated by the dynamic wave in reverse, and the dilute acid absorbs SO in the flue gas 3 And it is heated and condensed by the waste heat of the flue gas. The concentrated acid is filtered after removing impurities such as arsenic, and finally reaches the storage tank 13 .

[0017] as attached figure 1 Shown: a method for concentrating and purifying dilute acid by using the residual heat of smelting flue gas. When the flue gas produced by non-ferrous metal smelting is sent to acid production, the waste dilute acid with a concentration of about 20%-30% generated by the power wave reaches the dilute acid tank 10 , use the horizontal dilute acid pump 9 to pump it into the top of the concentration tower 2 and spray downwards, contact with the smelting flue gas at about 200°C-280°C from the flue gas inlet pipe 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com