Method for producing low ripple coefficient semiconductor super-radiation LED

A technology of superluminescence and corrugation coefficient, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of high technical difficulty, high cost requirements, and poor repeatability, so as to improve light transmittance, achieve low cost, and suppress the affected The effect of exciting oscillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

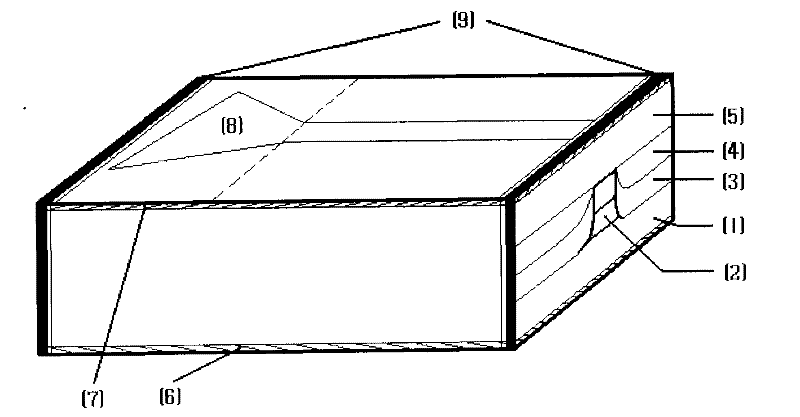

[0042] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail with reference to specific embodiments and drawings.

[0043] Such as figure 1 As shown, in order to achieve low ripple coefficient, it is necessary to minimize the cavity surface optical feedback,

[0044] The main measures adopted by the present invention are as follows:

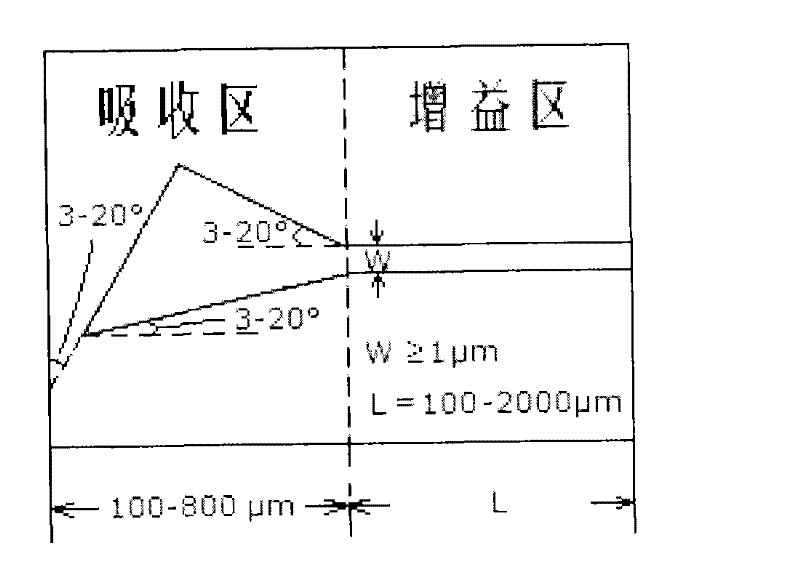

[0045] 1. Waveguide structure of "oblique triangle absorption zone"

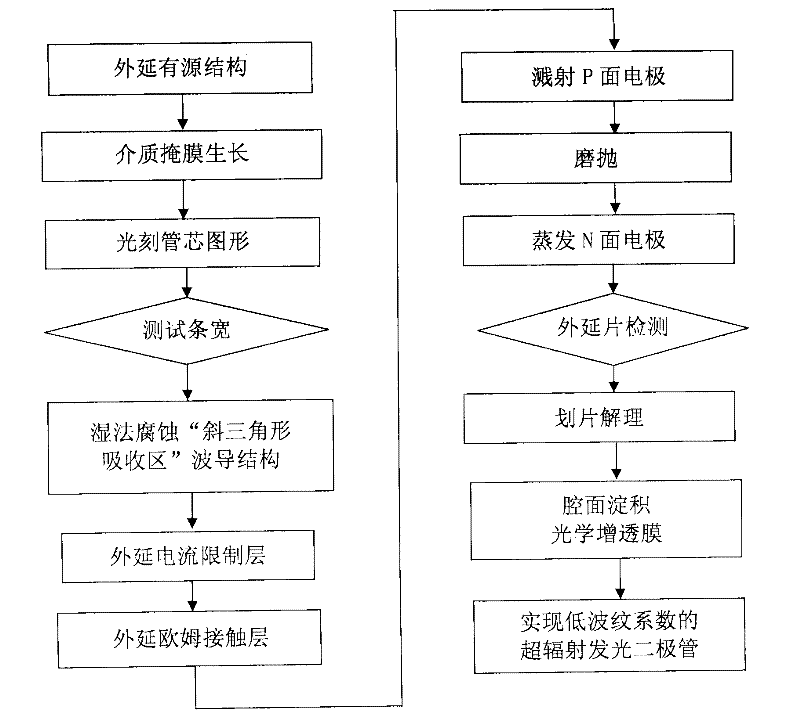

[0046] First, the metal-organic chemical vapor deposition (MOCVD) epitaxial technology is used to epitaxially grow the active structure of the die on the InP substrate, including the N-InP buffer layer and the active layer.

[0047] Secondly, a chemical vapor deposition method is used to grow a layer of silicon dioxide mask on the active structure, and the mask is etched by photolithography technology to etch a strip waveguide gain area on one side, and an "oblique triangle" o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com