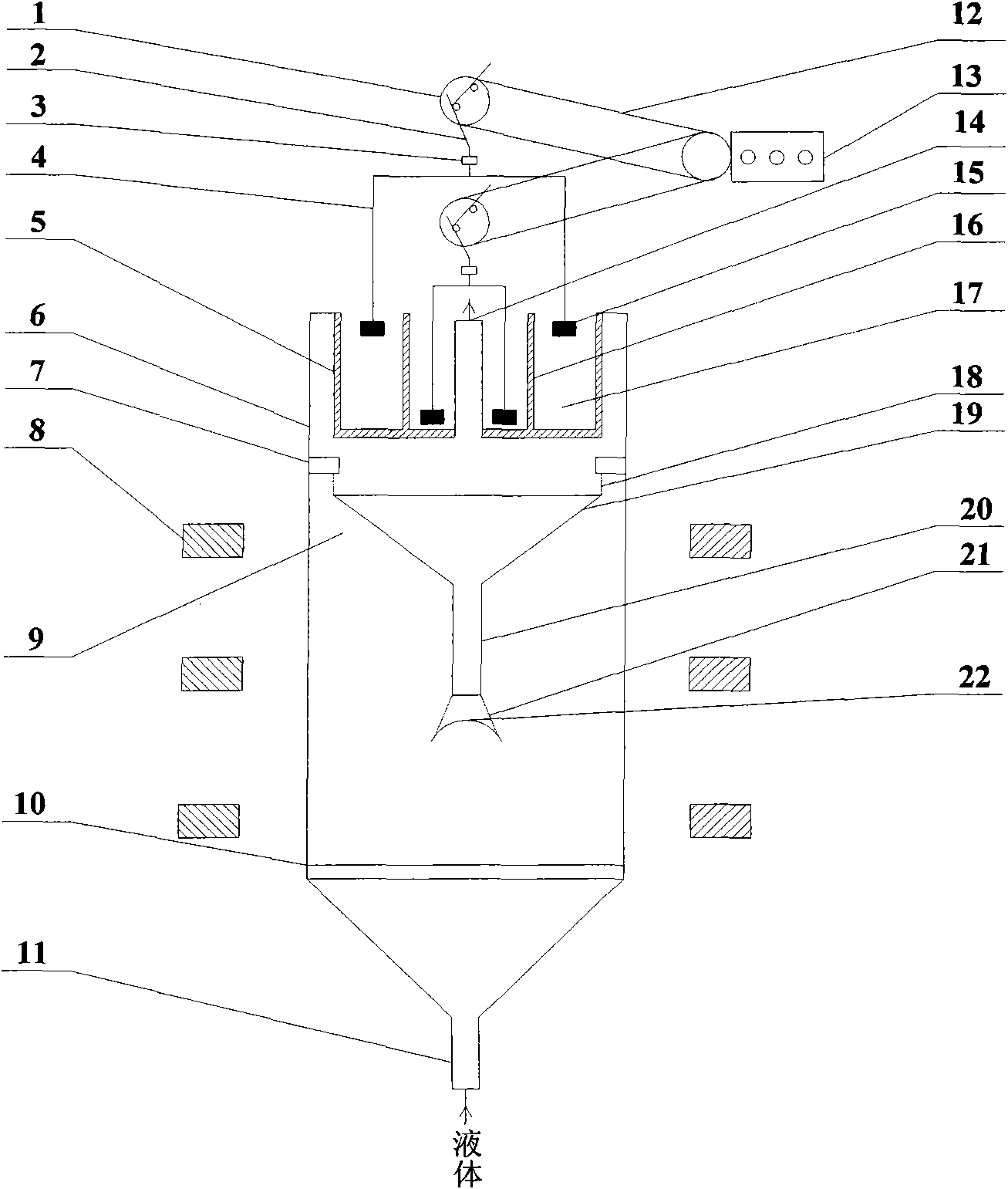

Magnetic-particle in-situ separation device for magnetic stabilization fluidized bed

A technology of in-situ separation and magnetic particles, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of increasing energy consumption of magnetic field fluidized bed, uneven distribution of fluid, loss of separation medium, etc., to achieve repeatable Use, improve operating efficiency, and reduce disturbance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

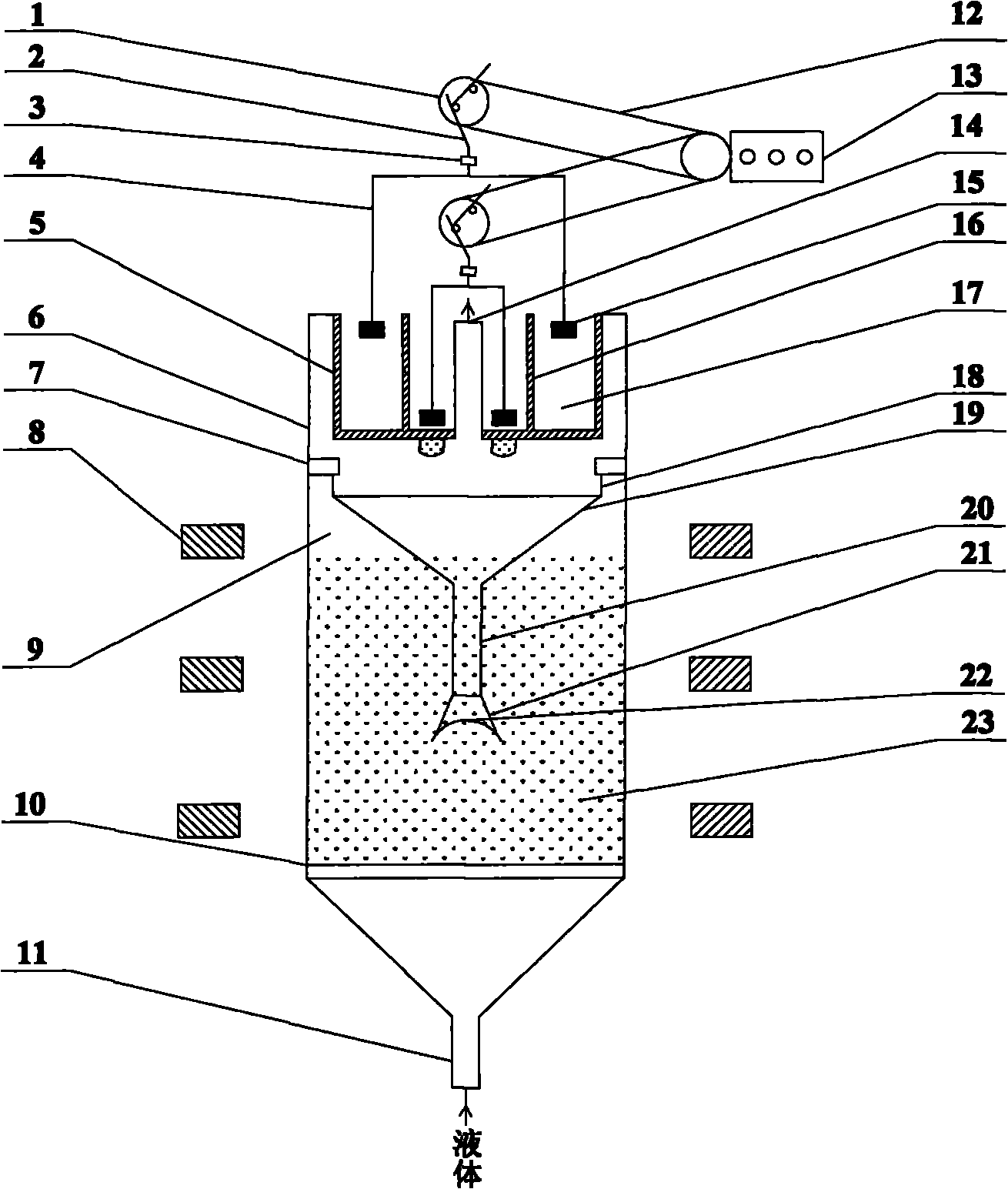

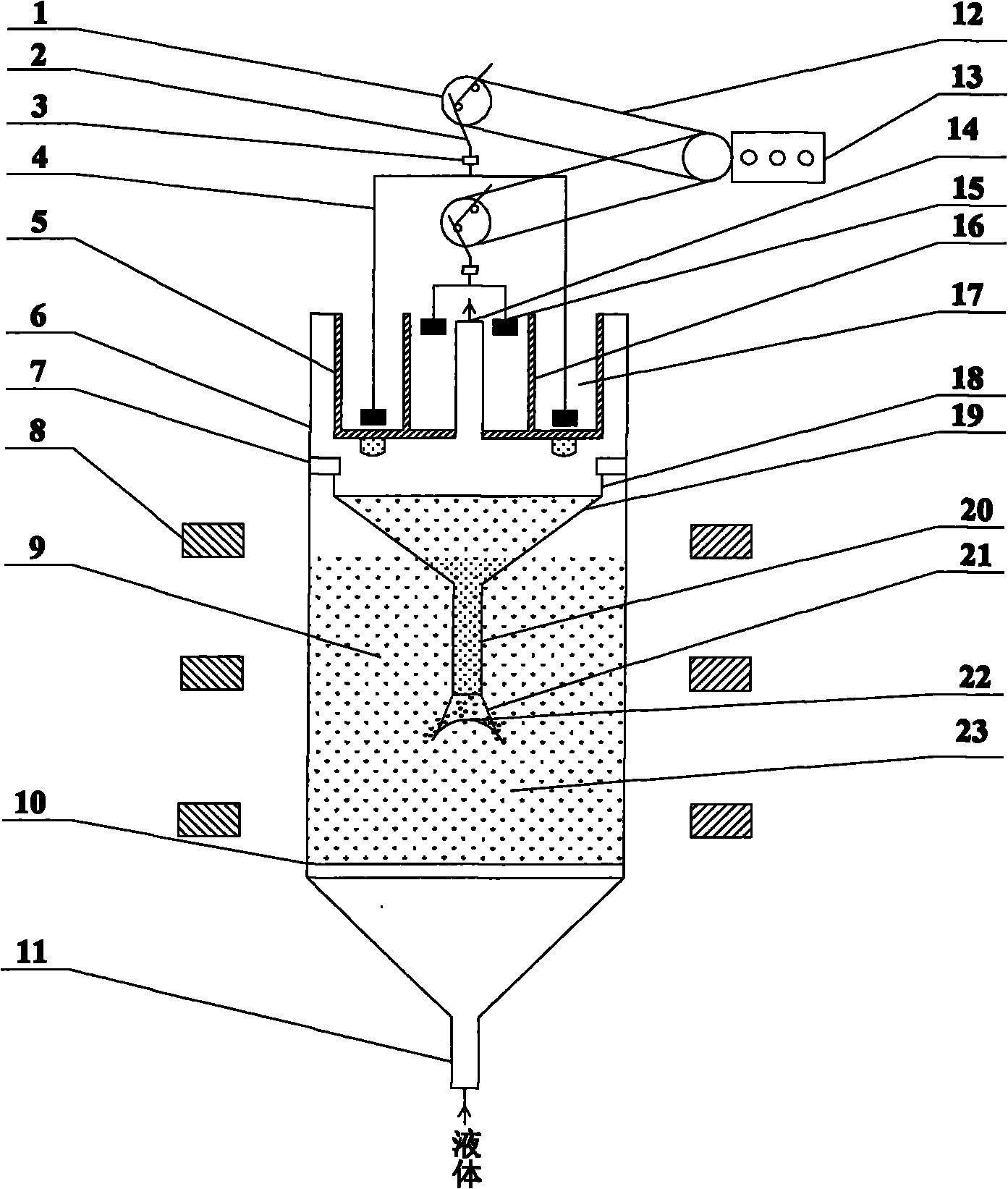

[0037] The magnetic particle 23 of the present embodiment is the Cu that grafts glycidyl methacrylate and iminodiacetic acid on the surface of magnetic polyvinyl acetate microspheres. 2+ Chelated affinity adsorption magnetic microspheres (PVA-g-GMA-IDA-Cu 2+ ), the experiment proves that the magnetic microsphere has superparamagnetism.

[0038] Magnetic microspheres (PVA-g-GMA-IDA-Cu 2+ ) adsorption reaction of laccase protein, normal temperature 25 ℃, magnetic microspheres (PVA-g-GMA-IDA-Cu 2+ ) as an adsorption carrier, magnetic microsphere concentration 100mg / ml in the magnetically stable fluidized bed 9, liquid feed port 11 protein concentration 0.1mg / ml, carry out magnetic microsphere (PVA-g-GMA-IDA-Cu 2+ ) continuous in-situ separation operation, during the adsorption process, samples were taken regularly at the discharge port 14, and the outflow of magnetic particles 23 was measured by centrifugation, and no obvious outflow of magnetic microspheres was seen.

Embodiment 2

[0040] The magnetic particle 23 of this embodiment is an active Ni catalyst, and experiments have proved that the magnetic microsphere has superparamagnetism.

[0041] Carry out the reaction of caprolactam catalytic hydrogenation in the device of the present invention, reaction temperature 80 ℃, magnetic active Ni is used as catalyst, catalyst concentration 20% (w / v) in the magnetically stable fluidized bed 9, liquid feed inlet 11 contains dissolved hydrogen Caprolactam aqueous solution concentration 32% (w / v), carry out the continuous in-situ separation operation of active Ni in the magnetically stable fluidized bed 9 according to the above-mentioned method, in the adsorption process, regularly sample at discharge port 14, centrifuge and measure the outflow situation of active Ni , no obvious active Ni outflow.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com