Lithium ion battery cathode material as well as preparation method and application thereof

A polarity and reaction technology, applied in the field of electrochemistry, can solve the problems of increasing the process, etc., and achieve the effect of stable product quality, high reproducibility, and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

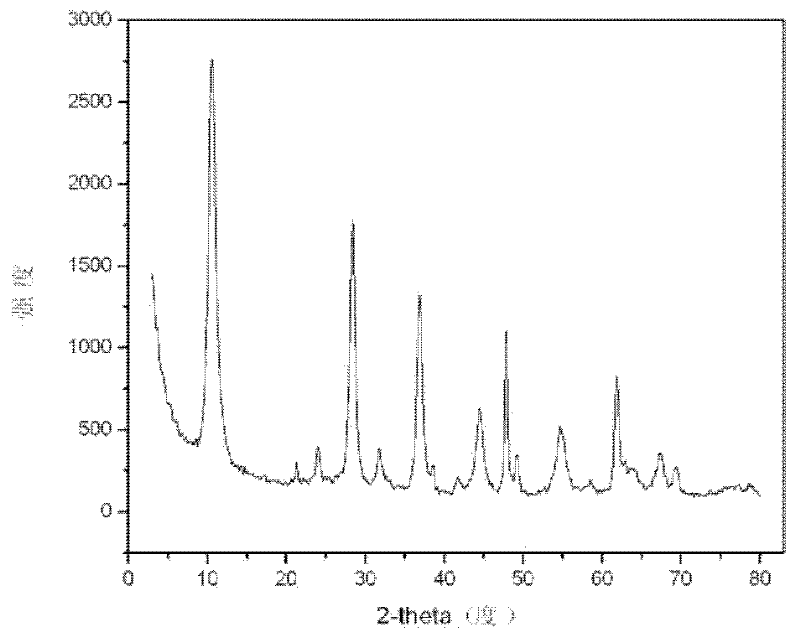

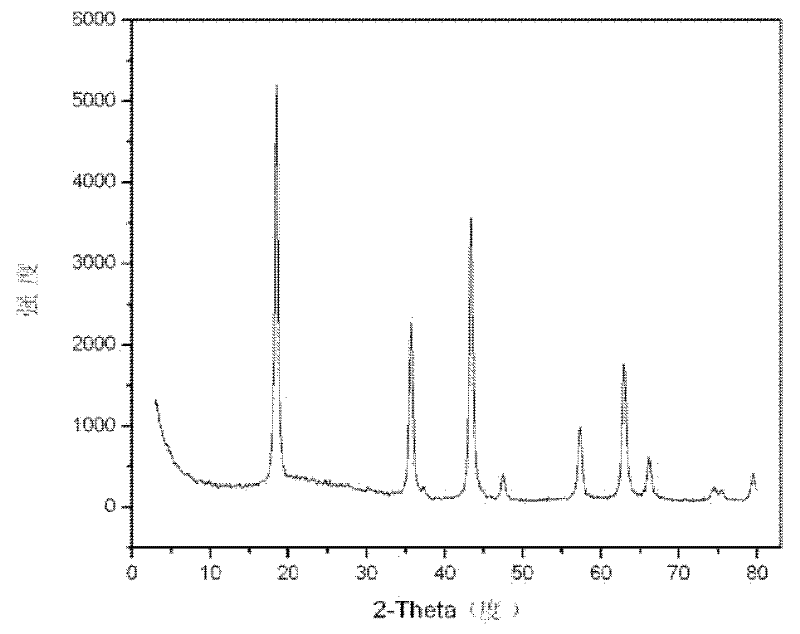

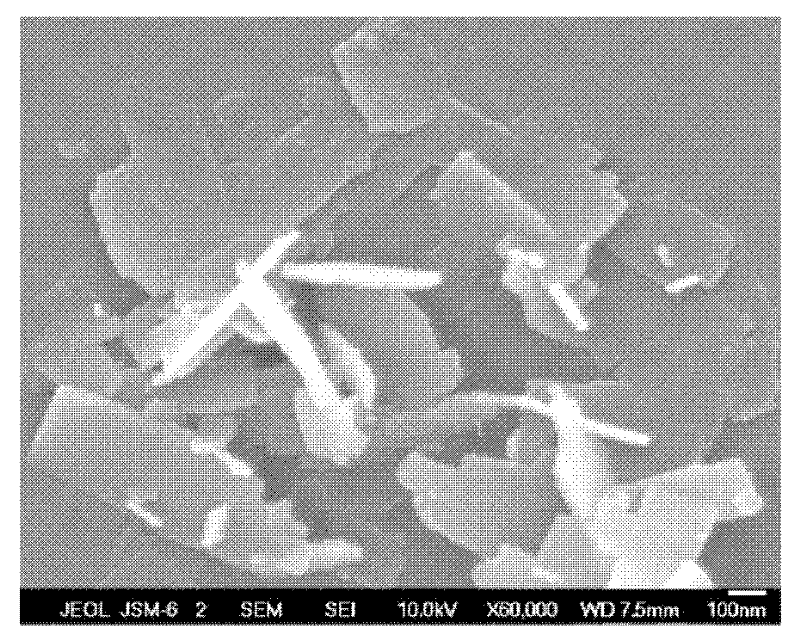

Image

Examples

Embodiment 1

[0032] 1) Take 1.7mL (5mmol) of tetrabutyl titanate (purchased from Beijing Jinlong Chemical Reagent Co., Ltd.) and add it to 25mL of absolute ethanol. 15-25° C., keep the humidity <10% RH, and stir for 30 minutes to obtain an ethanol solution of tetrabutyl titanate.

[0033] 2) Add 0.189g (4.5mmol) LiOH·H to the ethanol solution of tetrabutyl titanate obtained in step 1) 2 O(Alfa), continue to stir for 24h, until LiOH·H in the solution 2 O is completely dispersed in the solution until there is no more LiOH·H at the bottom of the container 2 Precipitation of O gives a mixed solution.

[0034] 3) Add 25 mL of water to the mixed solution obtained in step 2), adjust the pH value to 13 with 25% ammonia solution, and stir vigorously for 2 minutes. The solution first becomes colorless and transparent, and then gradually becomes a white latex solution. Before the solution solidifies, Quickly transfer the white latex solution into a 100mL Teflon hydrothermal reaction kettle, put th...

Embodiment 2

[0040] 1) Take 3.4mL (10mmol) of tetraisopropanol titanate (Sigma-Aldrich) and add it to 25mL of absolute ethanol. °C, keep the humidity <10%RH, and stir for 30 minutes to obtain an ethanol solution of tetraisopropanol titanate.

[0041] 2) Add 0.378g (9mmol) LiOH·H to the ethanol solution of tetraisopropanol titanate obtained in step 1) 2 O(Alfa), continue to stir for 24h, until LiOH·H in the solution 2 O is completely dispersed in the solution until there is no more LiOH·H at the bottom of the container 2 Precipitation of O gives a mixed solution.

[0042] 3) Add 25 mL of water to the mixed solution obtained in step 2), adjust the pH value to 13 with 25% ammonia solution, and stir vigorously for 2 minutes. The solution first becomes colorless and transparent, and then gradually becomes a white latex solution. Before the solution solidifies, Quickly transfer the solution to a 100mL Teflon hydrothermal reaction kettle, put the reaction kettle in an oven, keep it at 170°C fo...

Embodiment 3

[0044] 1) Take 5.1mL (5mmol) of tetrabutyl titanate (Beijing Jinlong Chemical Reagent Co., Ltd.) and add it to 25mL of absolute ethanol. 25° C., keep the humidity <10% RH, and stir for 30 minutes to obtain an ethanol solution of tetrabutyl titanate.

[0045] 2) Add 0.233g (4.5mmol) LiOC to the ethanol solution of tetrabutyl titanate obtained in step 1) 2 h 5 (Lithium ethoxide) (Sigma-Aldrich), continue to stir for 24h, until the lithium ethoxide in the solution is completely dispersed in the solution, until there is no precipitation of lithium ethoxide at the bottom of the container to obtain a mixed solution.

[0046] 3) Add 25 mL of water to the mixed solution obtained in step 2), adjust the pH value to 13 with 25% ammonia solution, and stir vigorously for 2 minutes. The solution first becomes colorless and transparent, and then gradually becomes a white latex solution. Before the solution solidifies, Quickly transfer the solution to a 100mL Teflon hydrothermal reaction ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com