Microfine structure and process for producing same

A manufacturing method and structure technology, applied in nanostructure manufacturing, microstructure technology, microstructure devices, etc., can solve problems such as interpolation and pattern density reduction, and achieve the effect of less defects and long-distance order

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

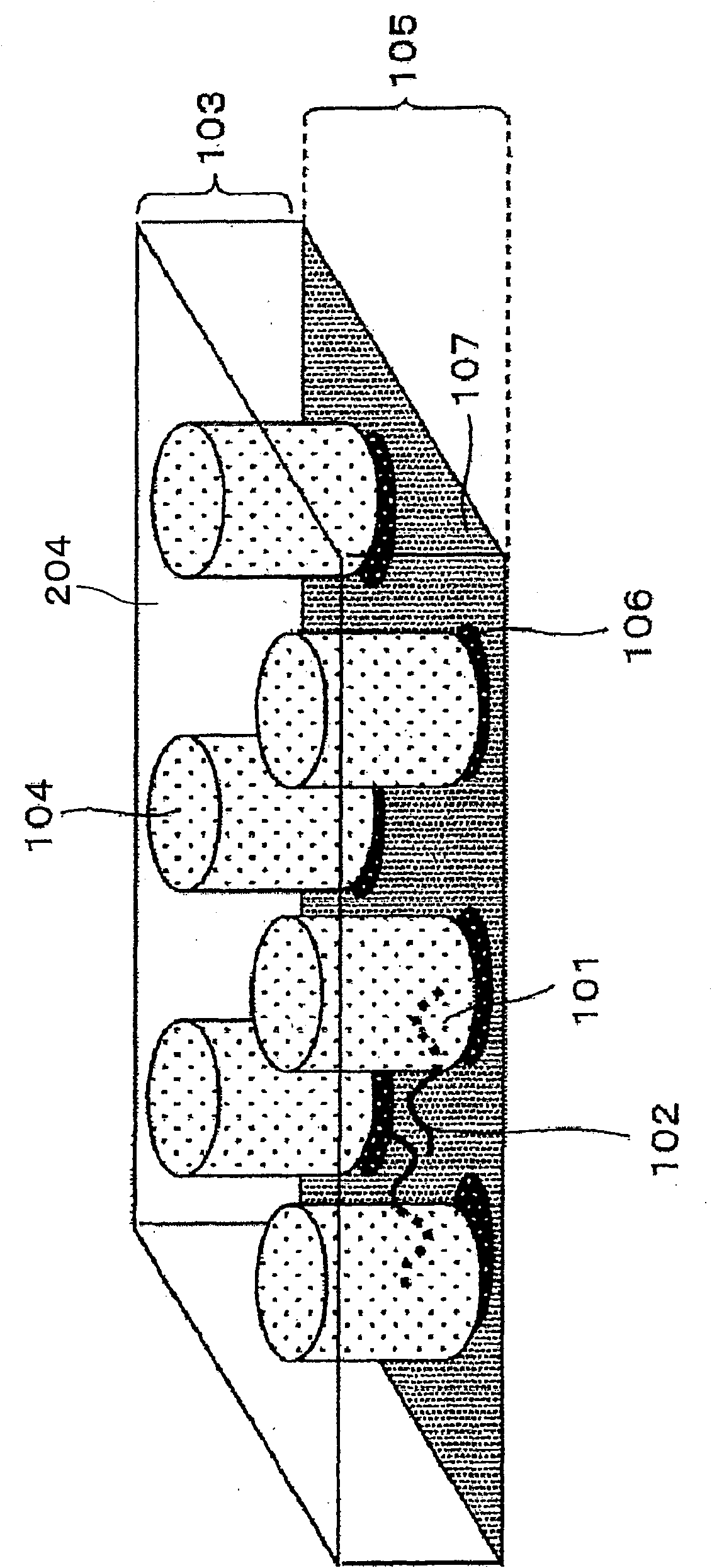

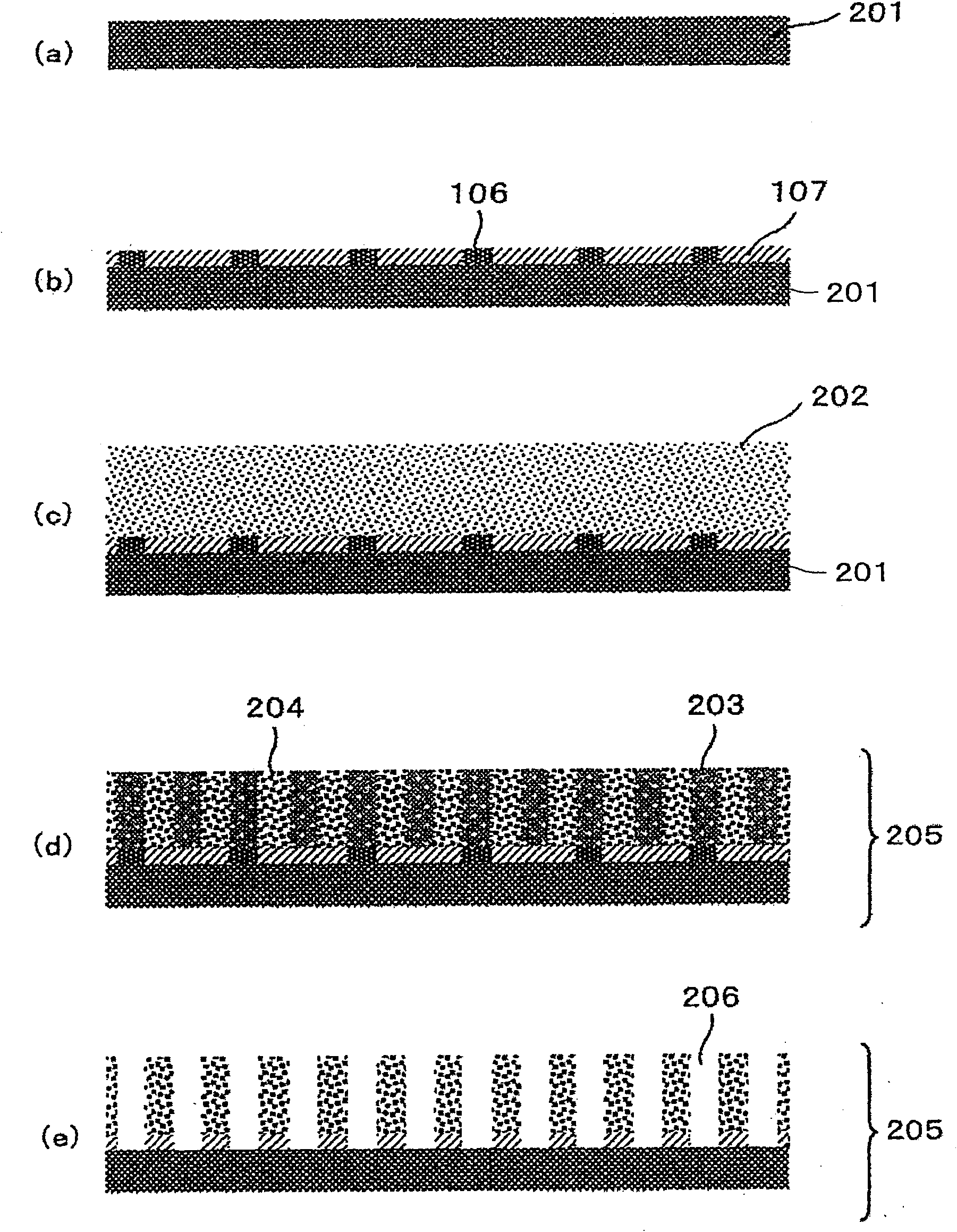

[0123] This example relates to the method for producing a polymer thin film having a first microstructure of the present invention, using PS-b-PMMA having a columnar microdomain structure as a polymer block copolymer, and the results of investigations are made with appropriate reference to comparative examples. side to explain.

[0124] (Preparation of Chemically Patterned Substrate)

[0125] The substrate is a silicon substrate with a natural oxide film. After grafting polystyrene on the entire surface, the grafted layer of polystyrene is patterned by electron beam (EB) photolithography to obtain polystyrene (PS) and polystyrene. Surface patterned substrates with methyl methacrylate (PMMA) having different wettability. The details will be described in turn below.

[0126]The polystyrene-grafted substrate was fabricated by the following method. First, a silicon substrate (4 inches) having a natural oxide film was washed with a pyran solution. Due to the oxidation effect of...

Embodiment 2

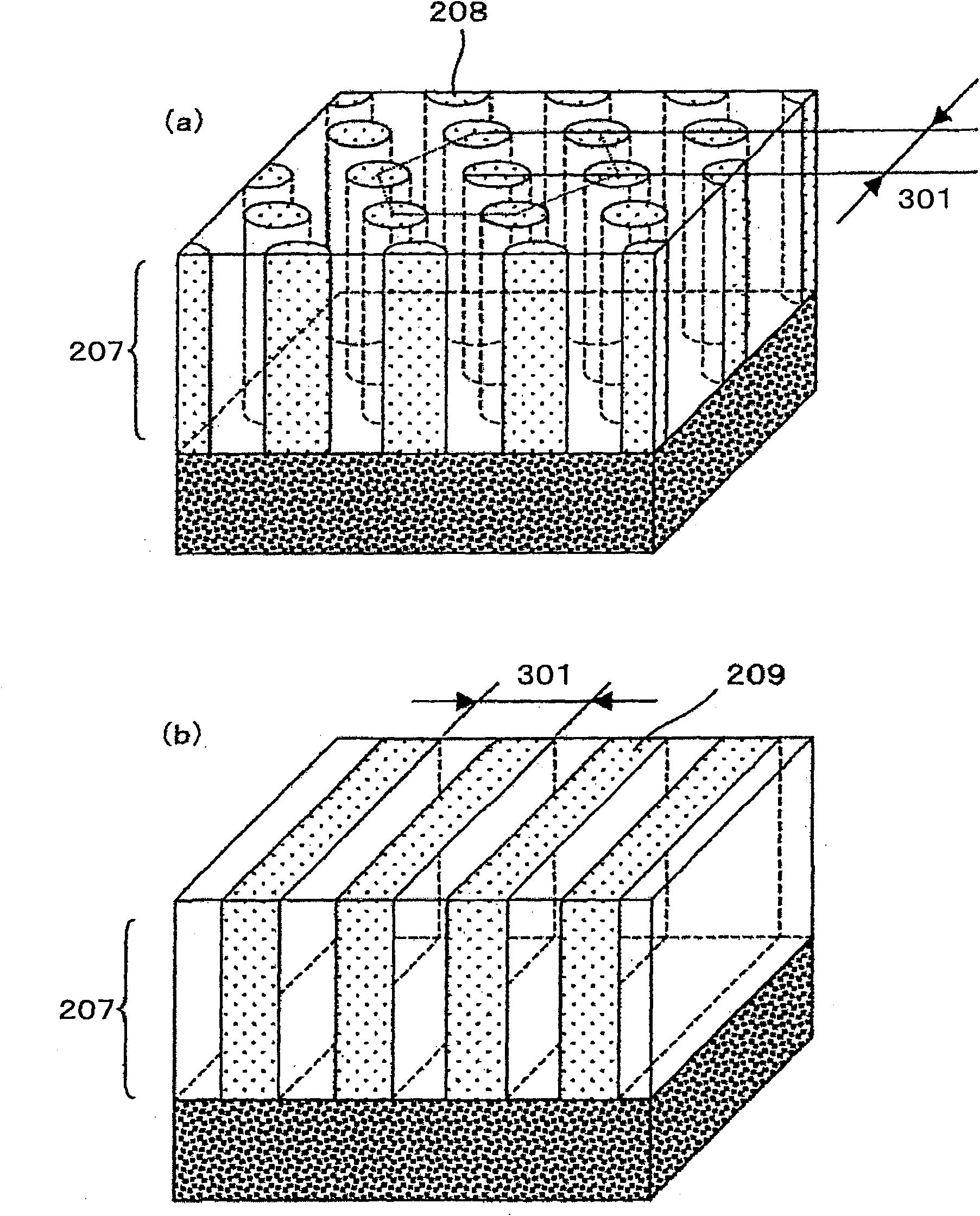

[0150] This embodiment relates to the manufacture method of the polymer thin film having the first microstructure of the present invention. As a polymer block copolymer, PS-b-PMMA that forms a sheet-like microdomain structure is used. The results of the study are appropriately referred to A comparative example will be described.

[0151] (Preparation of Chemically Patterned Substrate)

[0152] Figure 12 (a) to (c) are simulation diagrams of the pattern arrangement of the chemical pattern substrate. Same as in Example 1, the polystyrene grafted layer on the surface 320 of the polystyrene grafted substrate is patterned by EB photolithography, and the silicon substrate exposes a line-like region 330 with a width of r on the surface of the polystyrene grafted layer. , to fabricate chemically patterned substrates arranged in parallel with lattice spacing d. The pattern configuration on the fabricated substrate is as Figure 12 shown. On one substrate cut out from the pattern re...

Embodiment 3

[0161] This embodiment relates to the manufacturing method of the polymer thin film having the first fine structure of the present invention, as the polymer block copolymer, adopts PS-b- polydimethylsiloxane (PDMS) to carry out the research result, while appropriate It demonstrates with reference to a comparative example.

[0162] (Preparation of chemically patterned substrate)

[0163] The polystyrene-grafted substrate was produced in the same manner as in Example 1, and the surface state of the polystyrene-grafted substrate was evaluated. As a result, it was confirmed that a polystyrene-grafted film was formed on the surface of the silicon substrate.

[0164] Same as Example 1, the polystyrene grafted layer on the surface of the polystyrene grafted substrate was patterned by EB photolithography, and a circular area of diameter r of the silicon substrate was exposed on the surface of the polystyrene grafted layer, and a crystal was produced. A chemically patterned substrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com