Method for preparing silver/graphene antimicrobial composite material

A composite material and graphene technology, applied in botany equipment and methods, fungicides, chemicals for biological control, etc., can solve problems affecting safety, uneven dispersion of silver particles, affecting antibacterial performance, etc., to achieve Great bioirritancy, excellent antimicrobial properties, uniform size and shape effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] A kind of preparation method of silver graphene antibacterial composite material provided by the invention comprises:

[0039] a) provide the aqueous solution of reduced graphene oxide-polystyrene sodium sulfate complex;

[0040] b) heating the aqueous solution of the complex in step a) to 50°C to 70°C;

[0041] c) adding a silver nitrate solution to the heated composite aqueous solution in step b) and reacting to obtain a silver / graphene antibacterial composite material.

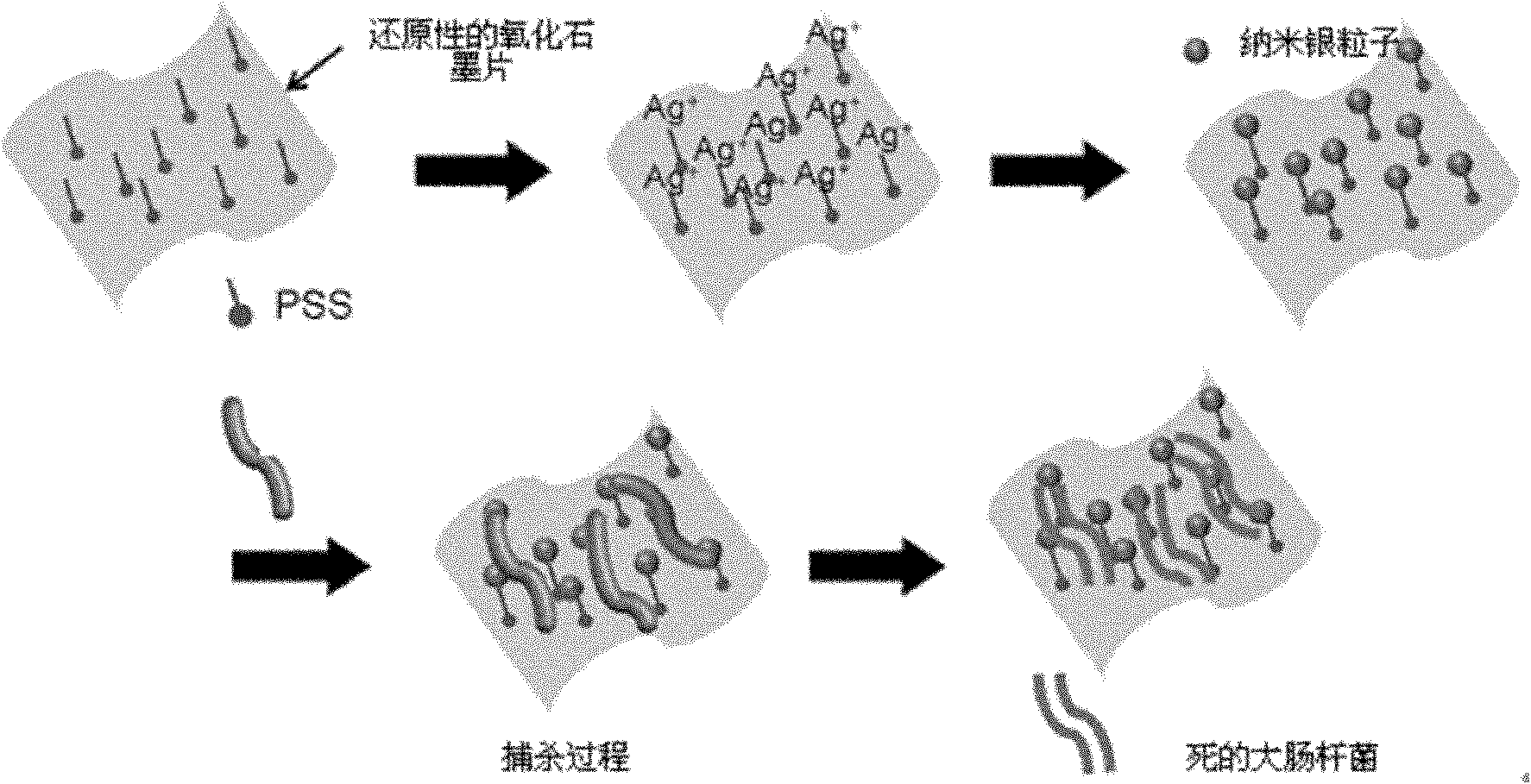

[0042] Such as figure 1 Shown is a schematic diagram of the synthesis process of the silver / graphene antibacterial composite material and the process of killing Escherichia coli in the present invention. The silver ions provided by silver nitrate are first attached to the surface of the reduced graphene oxide sheet-polystyrene sodium sulfate composite due to the electrostatic adsorption of polystyrene sodium sulfate, and the silver ions are reduced in situ by the reduced graphene oxide sheet , for...

Embodiment 1

[0058] Preparation of Graphene Oxide

[0059] 30ml of 98% H 2 SO 4 , 10gK 2 S 2 o 8 , 10gP 2 o 5 The mixed solution was heated to 80°C, added 20g of graphite powder and stirred evenly to obtain a dark blue mixture, and then the mixture was cooled to room temperature;

[0060] The obtained product is washed with distilled water suction filtration until the pH value is neutral, and then the washed product is dried in air to obtain pre-oxidized graphite powder;

[0061] Get 20g of pre-oxidized graphite powder and add it to 460ml of 98% concentrated H at 0°C 2 SO 4 To obtain the fourth mixed solution, slowly add 60gKMnO under stirring and ice bath conditions 4 , adding KMnO 4 Keep the system temperature at 15°C during the process;

[0062] After adding KMnO 4 Afterwards, the fourth mixed solution was warmed up to 35°C and stirred for 2h, 920ml of distilled water was added, and then 2.8L of distilled water and 50ml of 30% H 2 o 2 , the product turns yellow;

[0063] ...

Embodiment 2

[0065] Take 100 mg of the graphene oxide sheet prepared in Example 1 and add it to 100 ml of distilled water. After ultrasonic dispersion, add 1 g of polystyrene sodium sulfate, stir to dissolve, add 100 μl of hydrazine hydrate, heat to reflux at 100°C for 24 hours, and filter the product with suction. The reduced graphene oxide-polystyrene sodium sulfate composite was obtained by lyophilization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com