Method for preparing selectively degraded ciprofloxacin photocatalyst

A selective, catalyst technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of difficult target removal, lack of selectivity, etc., to achieve improved efficiency and strong selectivity The effect of treating antibiotic wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

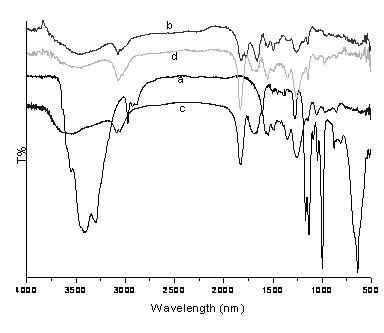

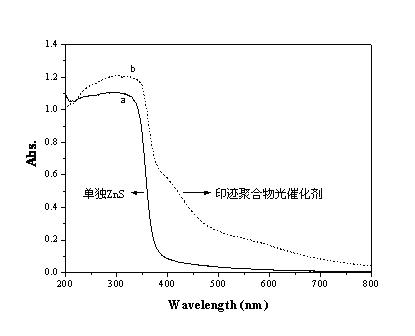

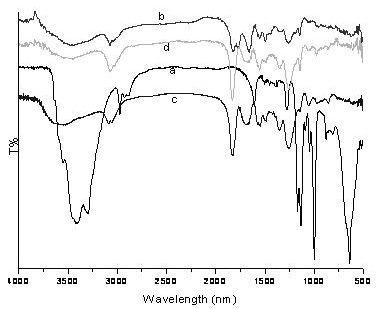

Image

Examples

Embodiment 1-4

[0021] Embodiment 1-4: (1) Hydrothermal synthesis of ZnS semiconductor materials: firstly, Zn(COOH) 2 and CS(NH 2 ) 2 Dissolve in an appropriate amount of distilled water at a mass ratio of 1:2 (6 mmol : 12 mmol), stir magnetically at a constant rate for 4 h to fully mix the two, and then add the solution to a polytetrafluoroethylene-lined reactor In this method, the total solution volume does not exceed 80% of the volume of the reactor, react at a constant temperature of 150 ° C for 24 h, and naturally cool at room temperature after the reaction is completed. Drying under vacuum at 60°C finally obtains ZnS semiconductor microspheres with uniform particle size.

[0022] (2) A certain amount of ZnS microspheres prepared by hydrothermal treatment was added to a certain amount of methanol solution dissolved in acrylamide so that the mass ratio of ZnS and acrylamide was 3:1 (15 mmol : 5 mmol). After stirring at room temperature for 20 h, the acrylamide-modified ZnS particles ...

Embodiment 5

[0031] Example 5: Use the photocatalyst prepared in (3) in Example 1 to degrade the mixed solution of ciprofloxacin and interfering substances (gatifloxacin, chloramphenicol) at the same concentration, and calculate the degradation efficiency of different substances And then calculate its selectivity coefficient for different substances.

[0032] E% = ×100 % (1); D = (2); α= (3); α γ = (4)

[0033] where C 0 , C e are the initial and degraded concentrations of ciprofloxacin (mg L -1 ); D is the distribution coefficient, D CIP ,D M are the partition coefficients of ciprofloxacin and interfering substances, respectively; α is the selectivity coefficient, α i , α n are the selectivity coefficients of imprinted and blank polymer photocatalysts, α r is the relative selectivity coefficient.

[0034] The experimental results show that the degradation efficiency of MIP-2 photocatalyst to ciprofloxaci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com