Strong-stability moderate-temperature neutral alpha-amylase high-producing bacterium and zymologic property thereof

A strong stability, amylase technology, applied in the direction of enzymes, bacteria, biochemical equipment and methods, etc., can solve the problem that the enzymatic properties of amylase cannot be fully satisfied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

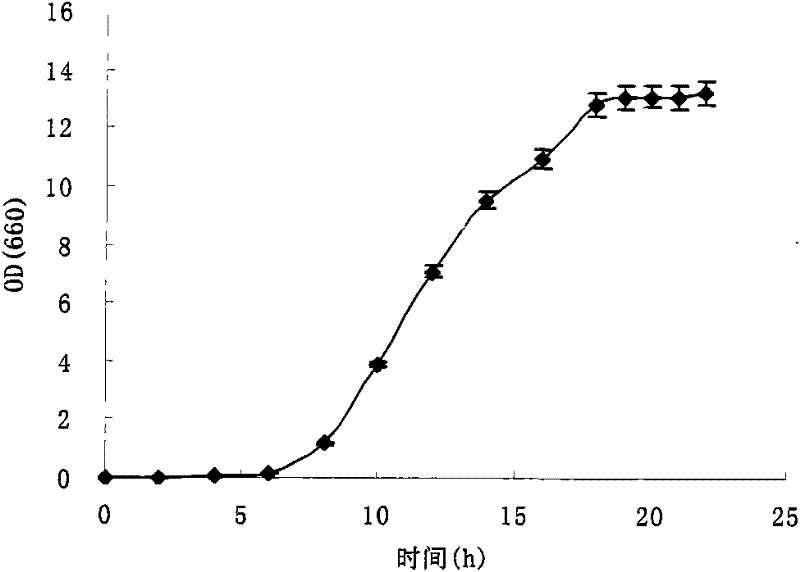

[0033] Embodiment 1: Screening of amylase-producing strains

[0034] Primary screening: Dissolve 1g of soil samples around the starch processing plant in 50mL of sterile water, shake well to make a soil suspension, and enrich the spores in a water bath at 80°C for 20 minutes; dilute the soil suspension to different times and take 200μL to spread on On the solid plate of the above-mentioned screening medium, after culturing for 48 hours, pick several single colonies with large hydrolysis circles / diameters for streaking and isolation, and store them in the seed slant medium.

[0035] Re-screening: Shake flask re-screening of several strains obtained from the primary screening. The shake flask medium is the above-mentioned fermentation medium. At 37°C, 250r / min (rotary shaker), culture for 72h, and then measure the enzyme in the fermentation broth live, and the strain with the highest enzyme production was named XLG-1.

Embodiment 2

[0036] Embodiment 2: the mensuration of amylase activity

[0037] The determination of amylase activity adopts the national standard industrial α-amylase preparation method (QB1805.1-93).

[0038] Definition of enzyme activity unit: 1 mL of liquid enzyme, under the conditions of 60°C and pH 6.0, liquefies 1 mg of soluble starch in 1 minute, which is 1 enzyme activity unit, expressed in U / mL.

Embodiment 3

[0039] Embodiment 3: middle temperature neutral amylase enzymatic property

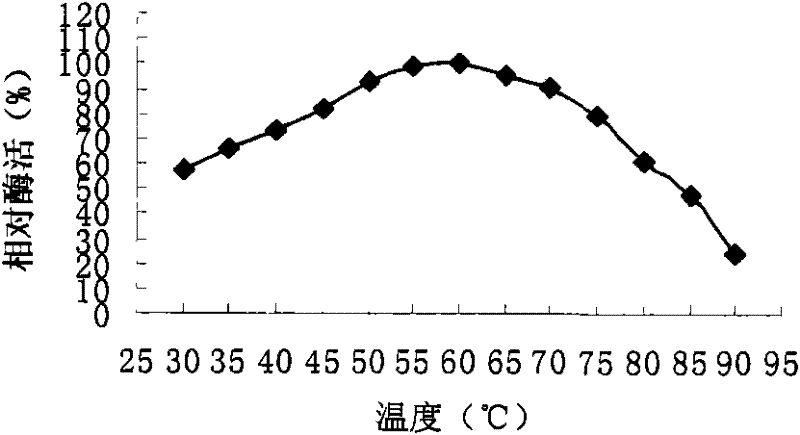

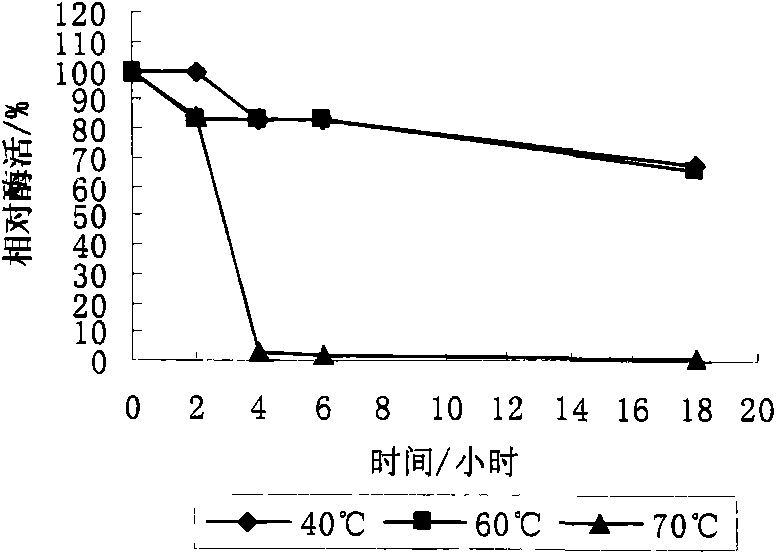

[0040] (1) Effect of temperature on enzyme activity and enzyme thermal stability

[0041] In the same reaction system, the enzyme activity of the amylase was measured at 30-90°C, and the results were as follows: figure 2 As shown: the enzyme exhibits high enzyme activity between 30-85°C, indicating that the enzyme has a wide temperature adaptability range, and its optimum action temperature is 50-70°C. Store the enzyme solution at constant temperature at 40°C, 60°C, and 70°C for different periods of time to measure the residual enzyme activity. The results are as follows: image 3 As shown: 18 hours at 40°C and 60°C, more than 65% of the enzyme activity remains, while only 3% of the enzyme activity remains after 4 hours at 70°C, indicating that the enzyme activity is very stable below 60°C.

[0042] (2) Effect of pH on enzyme activity and acid stability

[0043] In the same reaction system, the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com