Method for producing mycophenolic acid from penicillium brevicompactum by high-efficiency accumulation

A technology of mycophenolic acid and Penicillium, applied in the field of high-efficiency cumulative production of mycophenolic acid by using Penicillium brevisdense, which can solve the problems of long cycle and no significant increase in production, and achieve the effect of high production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

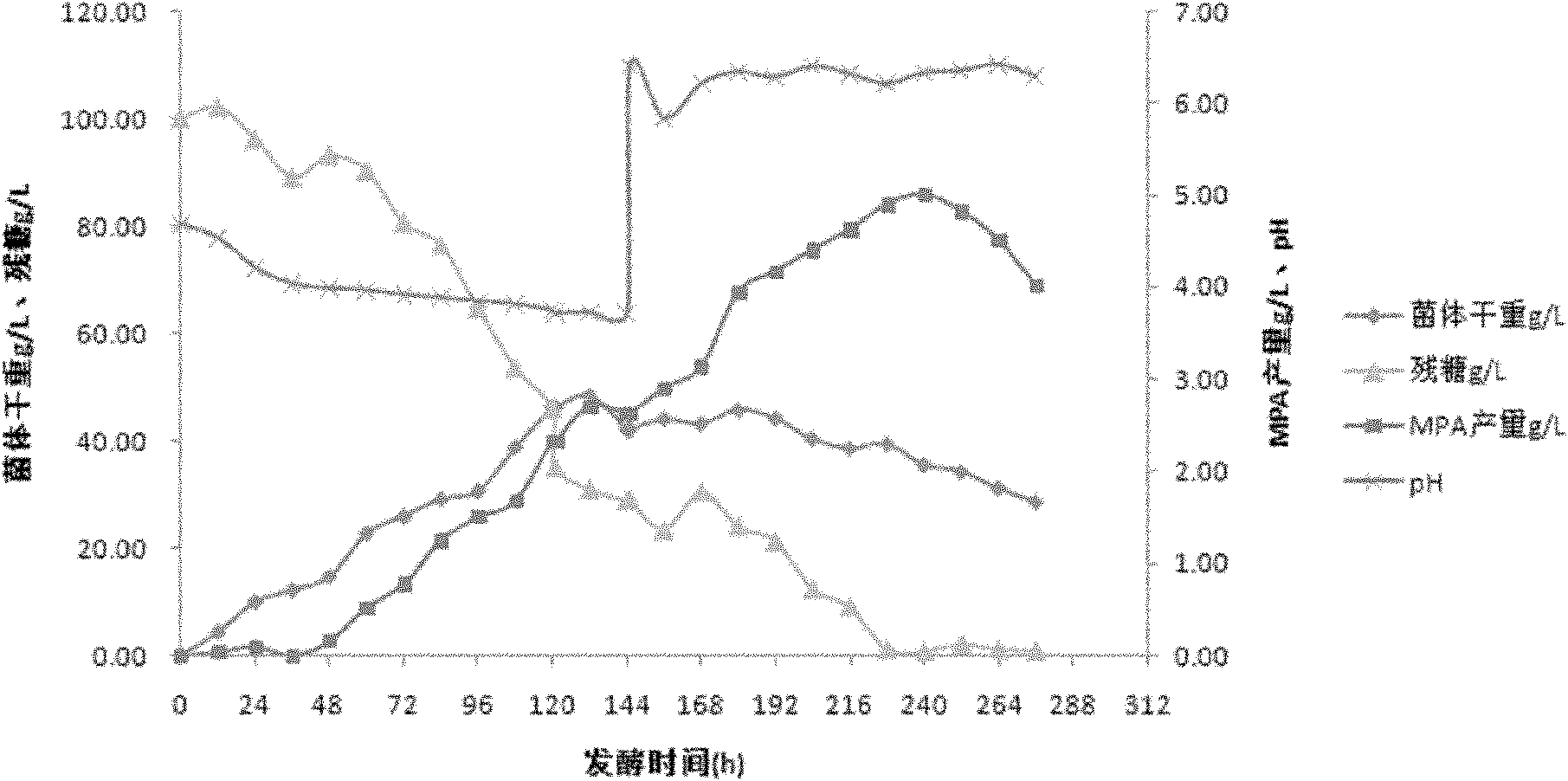

Image

Examples

Embodiment 1

[0022] The slant was cultured in PDA medium for 10 days and placed in a 4°C refrigerator to store the slant. Get the slanted seeds and use 30% glycerol to elute the spores to form a spore suspension, and 2% are inoculated into the seed shake flask medium (g / L): peptone 2.0, yeast extract 1.0, starch 1.0, glucose (C 6 h 12 o 6 ·H 2 O) 10.0, pH 6.5. Cultivate for 72 hours under the conditions of 28° C. and a rotating speed of 220 r / min, and inoculate 10% of the inoculum size into a 7L fermenter according to the volume of the medium. In the initial stage of fermentation, an optimized fermentation medium (g / L): glucose (C 6 h 12 o 6 ·H 2 O) 100.0, glycine (C 2 h 5 NO 2 ) 14.6, potassium dihydrogen phosphate (KH 2 PO 4 )3.0, magnesium sulfate (MgSO 4 ·7H 2 O) 1.0, Methionine (C 5 h 11 o 2 NS) 0.5, distilled water as the solvent, pH 4.6, the carbon and nitrogen sources were sterilized separately, and an appropriate amount of foam enemy was added.

[0023] The fermen...

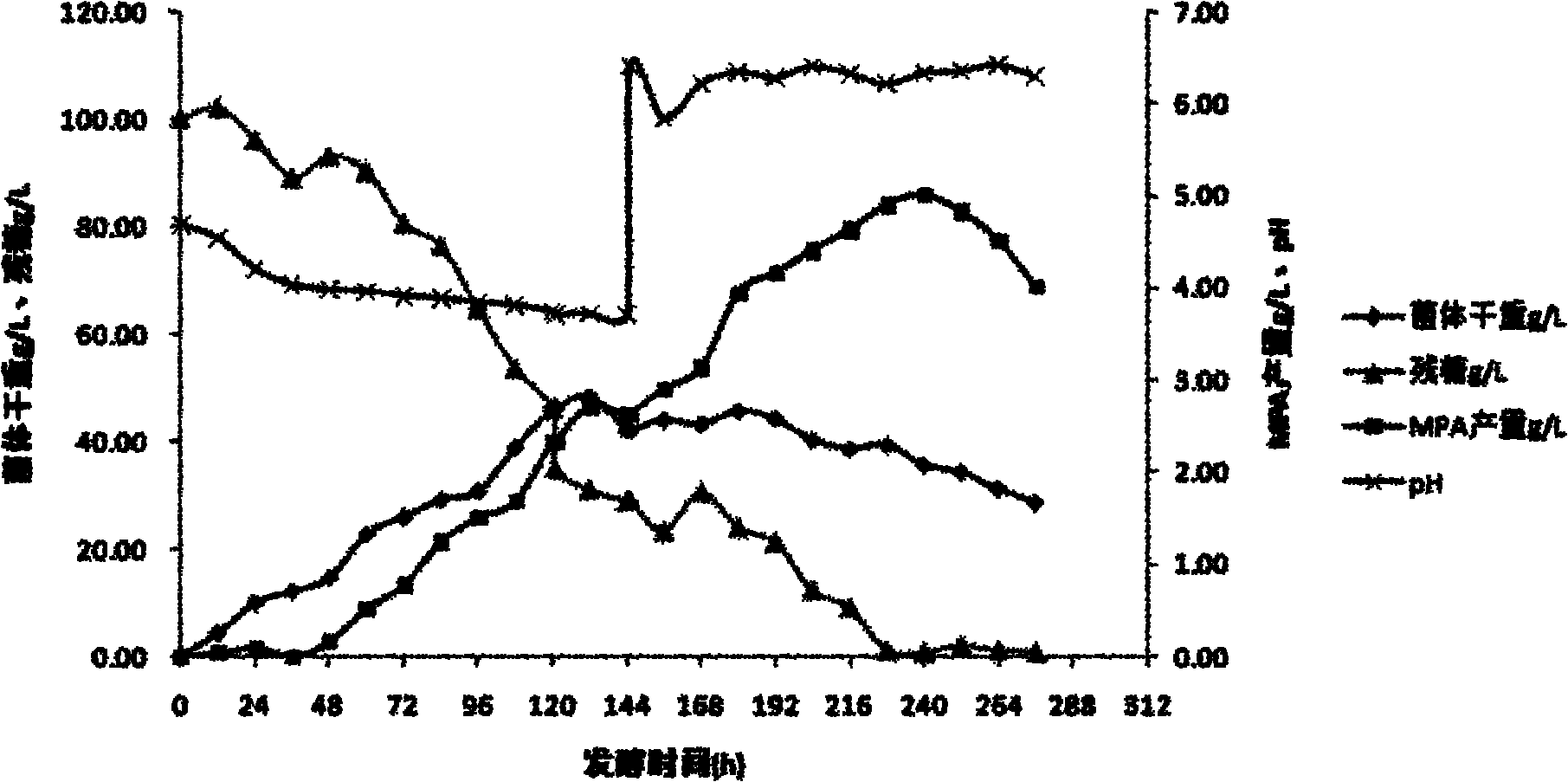

Embodiment 2

[0025] The slant was cultured in PDA medium for 10 days and placed in a 4°C refrigerator to store the slant. Get the slanted seeds and use 30% glycerol to elute the spores to form a spore suspension, and 2% is inoculated into the seed shake flask medium (g / L): peptone 2.0, yeast extract 1.0, starch 1.0, glucose (C 6 h 12 o 6 ·H 2 O) 10.0, pH 6.5. Cultivate for 72 hours under the conditions of 28° C. and a rotating speed of 220 r / min, and inoculate 10% of the inoculum size into a 7L fermenter according to the volume of the medium. In the initial stage of fermentation, an optimized fermentation medium (g / L): glucose (C 6 h 12 o 6 ·H 2 O) 150, glycine (C 2 h 5 NO 2 ) 14, potassium dihydrogen phosphate (KH 2 PO 4 )2.0, magnesium sulfate (MgSO 4 ·7H 2 O) 0.5, methionine (C 5 h 11 o 2 NS) 1.0, distilled water as the solvent, pH 4.4, the carbon and nitrogen sources were sterilized separately, and an appropriate amount of foam enemy was added.

[0026]Control the ferm...

Embodiment 3

[0028] The slant was cultured in PDA medium for 10 days and placed in a 4°C refrigerator to store the slant. Get the slanted seeds and use 30% glycerol to elute the spores to form a spore suspension, and 2% is inoculated into the seed shake flask medium (g / L): peptone 2.0, yeast extract 1.0, starch 1.0, glucose (C 6 h 12 o 6 ·H 2 O) 10.0, pH 6.5. Cultivate for 72 hours under the conditions of 28° C. and a rotating speed of 220 r / min, and inoculate 10% of the inoculum size into a 7L fermenter according to the volume of the medium. In the initial stage of fermentation, an optimized fermentation medium (g / L): glucose (C 6 h 12 o 6 ·H 2 O) 100.0, glycine (C 2 h 5 NO 2 ) 15, potassium dihydrogen phosphate (KH 2 PO 4 )4.0, magnesium sulfate (MgSO 4 ·7H 2 O) 0.5, methionine (C 5 h 11 o 2 NS) 0.5, distilled water as the solvent, pH 4.8, the carbon and nitrogen sources were sterilized separately, and an appropriate amount of foam enemy was added.

[0029] Control the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com