Method for preparing natural cellulose non-woven fabric in wet spunbond mode

A natural cellulose and cellulose technology, applied in the direction of single-component cellulose artificial filament, non-woven fabrics, fiber chemical characteristics, etc., can solve the problems of high cost, high cost, inexhaustible and other problems, and achieve The effect of shortening the process and reducing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

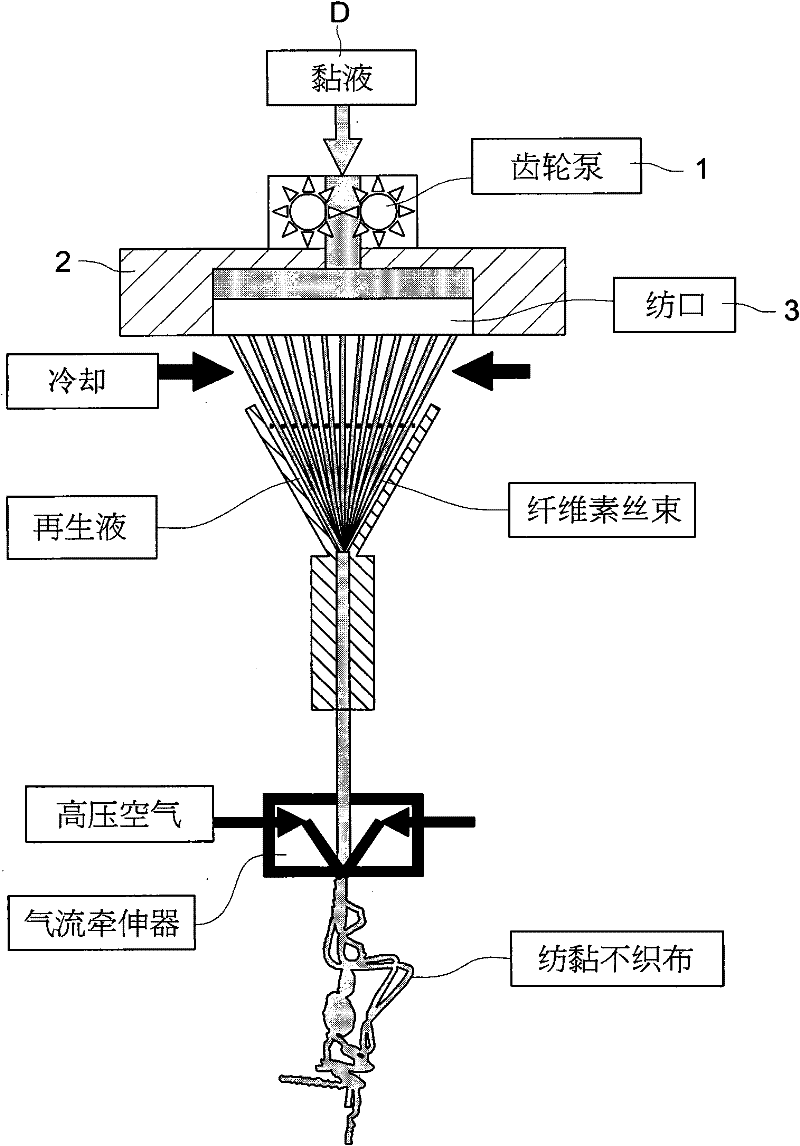

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

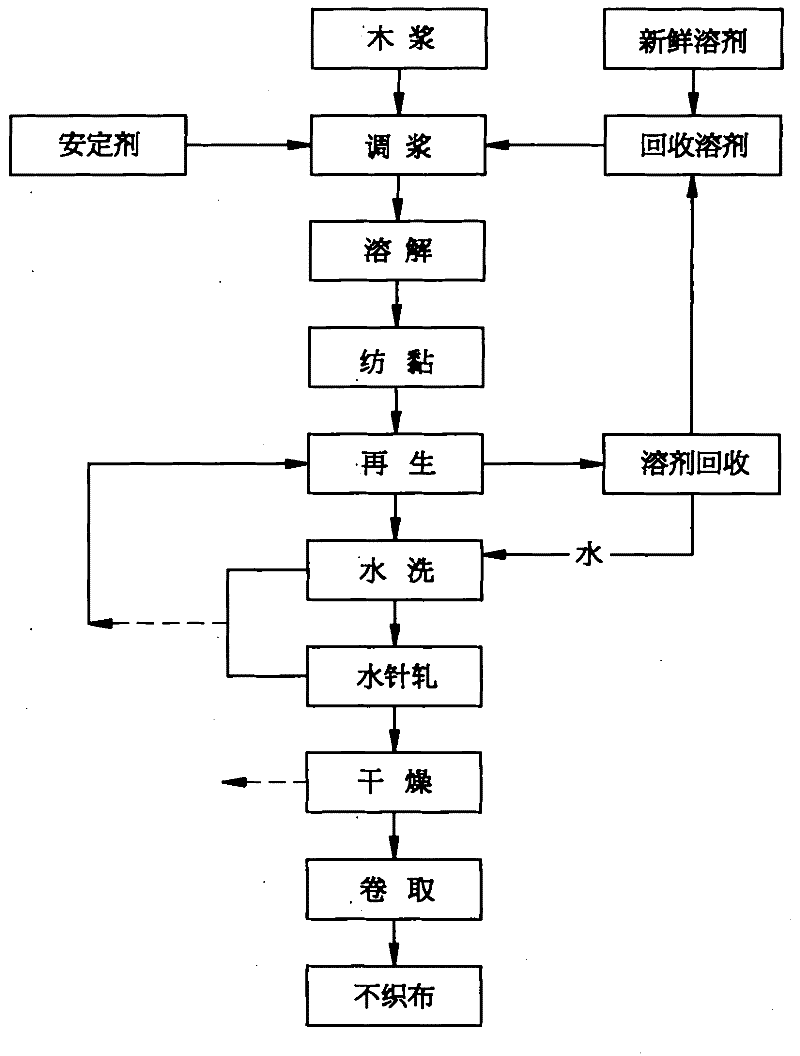

[0030] see Figure 1 to Figure 5 Shown, the present invention uses wet-type spunbonding mode to prepare the method for natural cellulose nonwoven fabric, and its step comprises:

[0031] a. Use wood pulp (pulp) as raw material; select long and short fiber wood pulp cellulose with an α-cellulose content of more than 65%, and its cellulose degree of polymerization (DP for short) is between 500 and 1200 ;

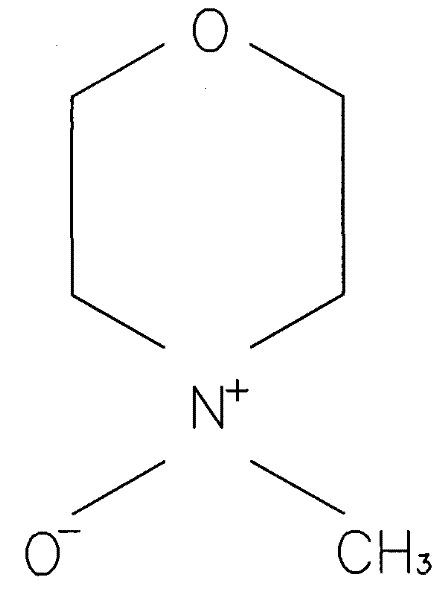

[0032] b. Add methylmorpholine N-oxide (N-methylmorpholine N-oxide, NMMO for short, its chemical structure is as follows figure 2 Shown) and phenyl oxazoline (1,3-phenylene-bis 2-oxazoline, BOX) in wood pulp, make it mix and dissolve into mucus (dope); After the wood pulp cellulose, oxidized methyl marin solvent and phenyloxazole additive are placed together, they are crushed at a high speed at a low temperature of 50°C to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com