Solar cell based on III-V group compound semiconductor/silicon nanometer bore column array and preparation method thereof

A III-V, silicon nanoporous column technology, applied in semiconductor devices, circuits, photovoltaic power generation, etc., can solve the problems of low conversion efficiency and high battery manufacturing cost, achieve low cost, increase short-circuit current, and wide-spectrum light absorption characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

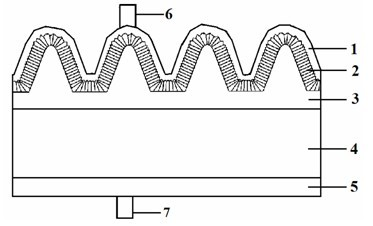

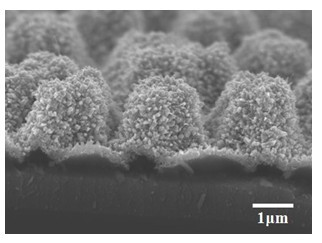

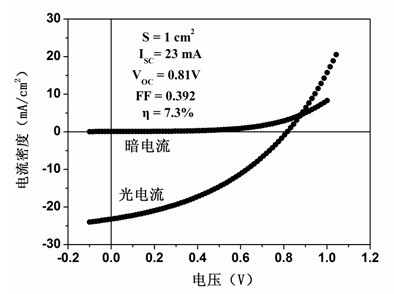

[0021] like figure 1 As shown, a solar cell based on a III-V compound semiconductor / silicon nanohole column array of the present invention includes a transparent conductive film 1 (indium tin oxide ITO), an n-type III-V compound semiconductor 2 (n-type unintentionally doped heterogallium nitride nanorod array), p-type silicon nanohole column array 3, p-type single crystal silicon layer 4 and metal conductive film layer 5 (aluminum), upper contact electrode 6 and lower contact electrode 7, in which p-type silicon nano Hole column array 3 covers the top surface of p-type single crystal silicon layer 4, n-type III-V group compound semiconductor 2 and p-type silicon nano-hole column array 3 form a heterojunction; transparent conductive film 1 is deposited on n-type III-V The surface of the group compound semiconductor 2 is used as the top electrode, and the bottom ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com