Method for manufacturing silicon-doped indium arsenide/gallium arsenide quantum-dot solar cell

A technology of solar cells and production methods, which can be applied in the directions of circuits, electrical components, and final product manufacturing, etc., can solve problems such as hindering large-scale popularization and use, and high cost of solar cells.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

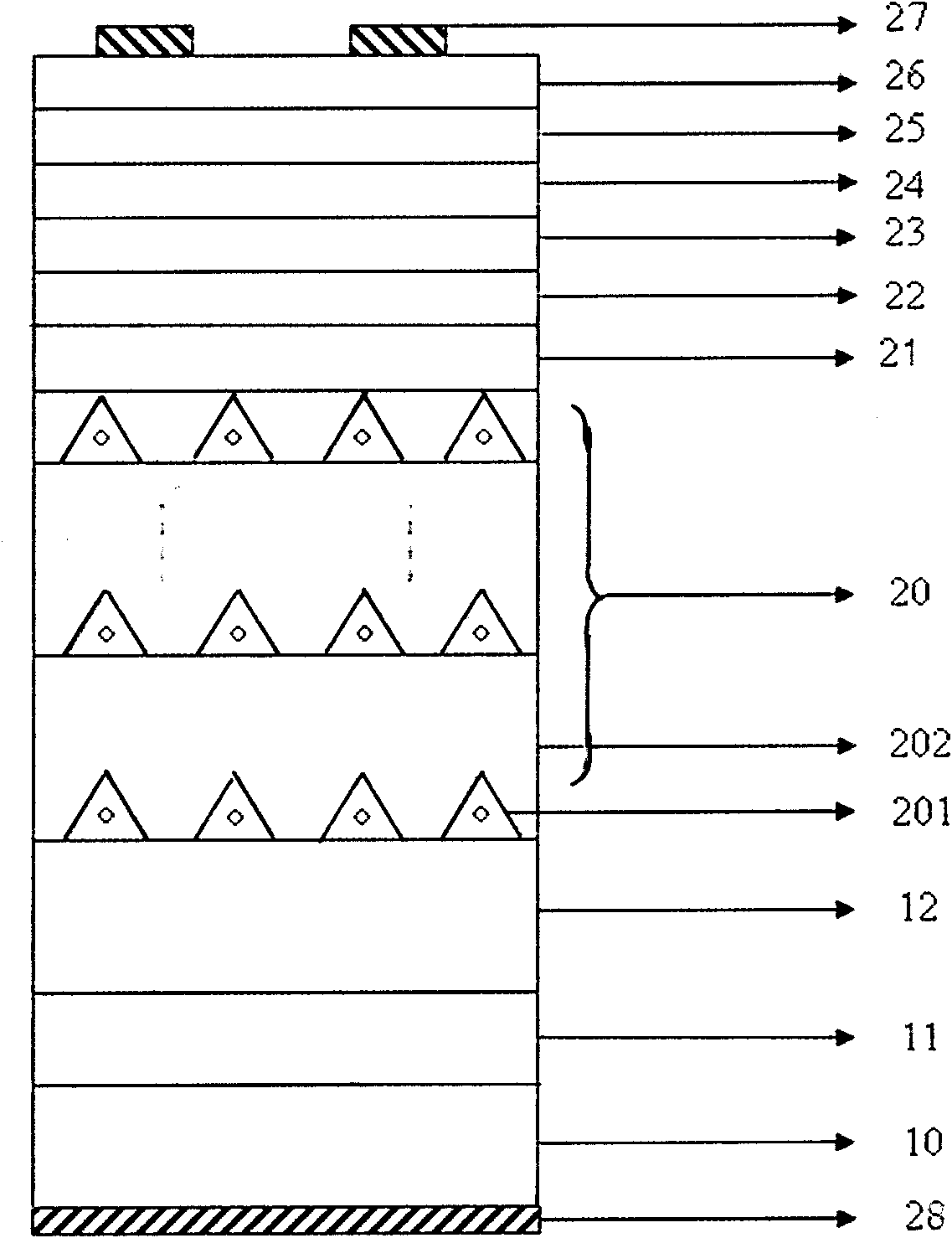

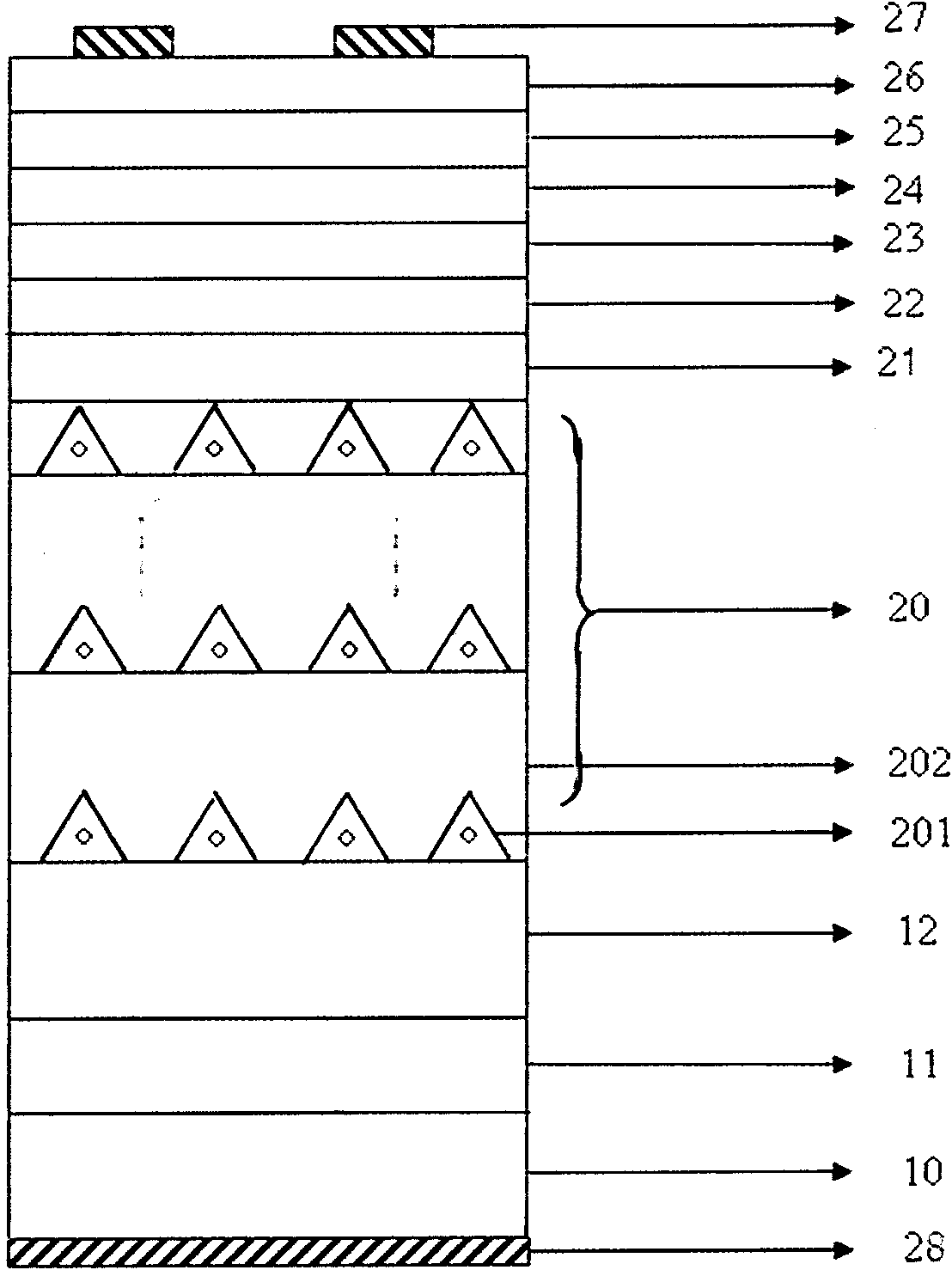

[0022] see figure 1 As shown, the present invention relates to a method for making a silicon-doped indium arsenide / gallium arsenide quantum dot solar cell, comprising the steps of:

[0023] Step 1: Select an n+ type GaAs single wafer 10 as the substrate, and the doping concentration is (0.6-1.4)*10 18 cm -3 ;

[0024] Step 2: grow an n-type GaAs layer 11 on the substrate 10 with a thickness of 500 nm, a growth temperature of 595° C., and a doping concentration of 1.0*10 18 cm -3 ; growing an intrinsic GaAs buffer layer 12 on the n-type GaAs layer 11 with a thickness of 400 nm and a growth temperature of 595° C.;

[0025] Step 3: growing multiple periods of quantum dot structures 20 on the intrinsic GaAs buffer layer 12, as the i absorbing layer of the solar cell, each period of the multiple periods of quantum dot structures 20 includes:

[0026] A silicon-doped InAs quantum dot layer 201 and a GaAs spacer layer 202 are grown sequentially from bottom to top; the number of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com