Double-schiff-base functionalized mesoporous silica antibacterial material and preparation method thereof

A technology of mesoporous silica and antibacterial materials, applied in botany equipment and methods, chemicals for biological control, animal repellants, etc., to achieve the effect of large specific surface area, broad application prospects, and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of FPMBA: Under nitrogen protection, put 2,3,5,6-tetrafluoro-p-phenylenediamine and terephthalaldehyde into an ethanol solution with a small amount of acetic acid according to a molar ratio of 1:1, and stir at room temperature 24h, obtained by suction filtration, washing and drying. The ethanol solution with a small amount of acetic acid is 2-3 drops of acetic acid in 25ml of ethanol.

[0033] The structural formula of the obtained bis-Sieffer base organic molecule is:

[0034] .

Embodiment 2

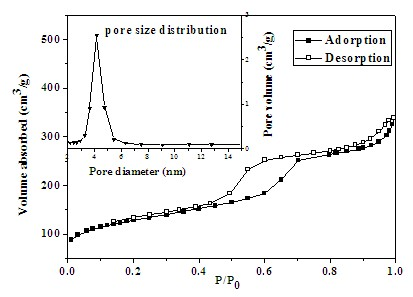

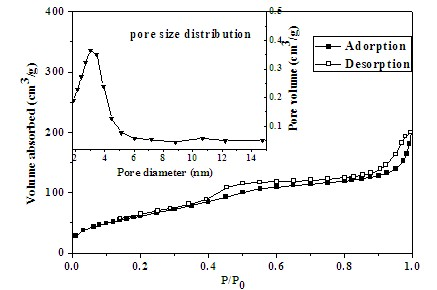

[0036] Dissolve 2g of non-ionic surfactant P123 in 15g of water and 60g of hydrochloric acid solution with a concentration of 2mol / L, stir at 2000r / min for 30min at room temperature until clear, place it in a water bath at 40°C, add ethyl orthosilicate 3.83g of ester, after pre-hydrolysis for 2h, add 0.49g of chloropropyl-triethoxy silylating reagent (the molar ratio of it to ethyl orthosilicate is 1:9), stir at 40°C for 24h, then transfer to the Put it in a stainless steel autoclave lined with polytetrafluoroethylene, put it in an oven at 100°C, age for 24 hours, filter it, wash it with water, dry it naturally in the air, and finally extract it in ethanol hydrochloric acid solution for 24 hours to remove the surfactant. Dry at room temperature to obtain mesoporous silica (SBA-Cl-10%) containing 10% of chlorine groups in the total silicon. Take 1 g of SBA-Cl-10% solid powder and disperse it in 50 ml of anhydrous toluene, and stir it into a homogeneous solution under nitrogen p...

Embodiment 3

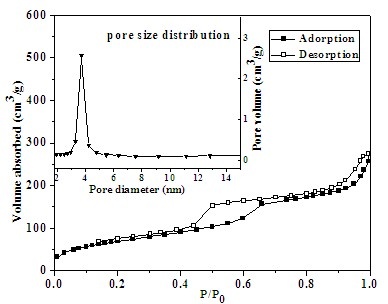

[0038]Dissolve 2g of non-ionic surfactant P123 in 15g of water and 60g of hydrochloric acid solution with a concentration of 2mol / L, stir at 2000r / min for 30min at room temperature until clear, place it in a water bath at 40°C, and add tetraethyl orthosilicate 3.61g, after pre-hydrolysis for 1h, add 0.74g of chloropropyl-triethoxysilylating reagent (the molar ratio of it to ethyl orthosilicate is 1:5.7), stir at 40°C for 24h, then transfer to poly In a stainless steel autoclave lined with tetrafluoroethylene, put it in an oven at 100°C, age for 24 hours, filter, wash with water, dry naturally in the air, and finally extract in ethanol hydrochloric acid solution for 24 hours to remove surfactant Drying under low temperature to obtain mesoporous silica (SBA-Cl-15%) containing 15% of chlorine groups in the total silicon. Take 1 g of the above solid powder and disperse it in 50 ml of anhydrous toluene, stir and reflux at 110° C. under nitrogen protection to form a homogeneous solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com