Novel nickel-based LPG water vapor reforming catalyst and preparation method thereof

A technology of steam reforming and catalyst, applied in chemical instruments and methods, inorganic chemistry, bulk chemical production, etc., can solve problems such as catalyst deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

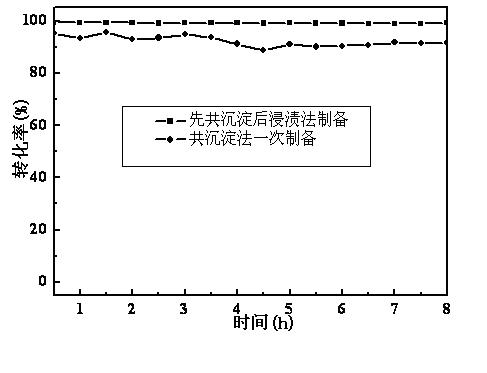

[0019] According to the molar ratio n(Mg):n(Al) =0.5:1, weigh 87.5 g Al(NO 3 ) 3 9H 2 O and 29.9 g Mg(NO 3 ) 2 ·6H 2 O was dissolved in 120 mL deionized water. At the same time, the preparation of Na 2 CO 3 (1 M) and NaOH (2 M) as a precipitant. Slowly drop the above alkaline precipitant aqueous solution into a beaker with a stirring device containing a mixed aqueous solution of metal cations for reaction; the stirring speed is 160 rpm, and the precipitation reaction is carried out at room temperature 60 ° C. After the precipitation reaction, keep the mixed solution The pH value is around 9.5 and aged at 60°C for 2 hours with stirring, the resulting precipitate is washed several times, and filtered at 110 o Dry overnight in a C drying oven; then grind into fine powder, and bake in a muffle furnace at 800° C. for 20 hours to obtain a magnesium-aluminum composite oxide carrier. Weigh 4.5g of magnesium-aluminum composite oxide carrier and impregnate it into 3 ) 2 .6H ...

Embodiment 2

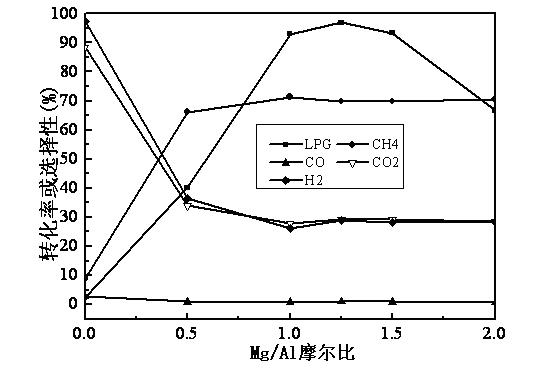

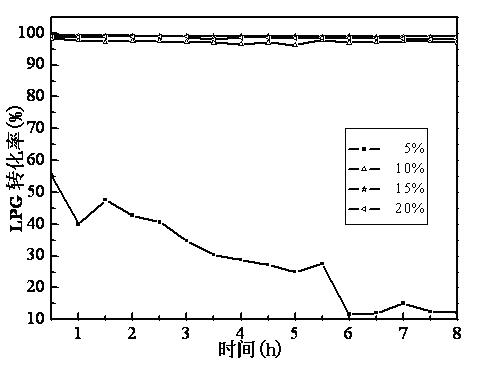

[0021] According to the method in Example 1, by adding different masses of Mg(NO 3 ) 2 ·6H 2 O and Al(NO 3 ) 3 9H 2 O to prepare Ni / Mg with different Mg / Al molar ratios x(Al) catalyst (see Table 1). At the same time, in order to investigate the effect of different nickel content on the catalytic performance of the catalyst, a series of Ni / Mg with different nickel content were prepared under the fixed Mg / Al ratio of 1.25. 1.25 (Al) catalyst (see Table 1). At the same time, Table 1 also lists the specific surface, pore volume, pore diameter and actual Mg / Al ratio of different catalysts.

[0022]

[0023] a Measured by SEM.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com