Heat-pump energy-saving separating device for extracting trichlorosilane by adopting static mixing booster and method

A technology for purifying trichlorosilane and static mixing, applied in the field of rectification, can solve the problems of high equipment investment and energy consumption, high rectification tower, large reflux, etc., and achieves improved heat exchange efficiency, reduced energy consumption, and reduced energy consumption. The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further elaborated below in conjunction with example, but does not produce any limitation to the present invention.

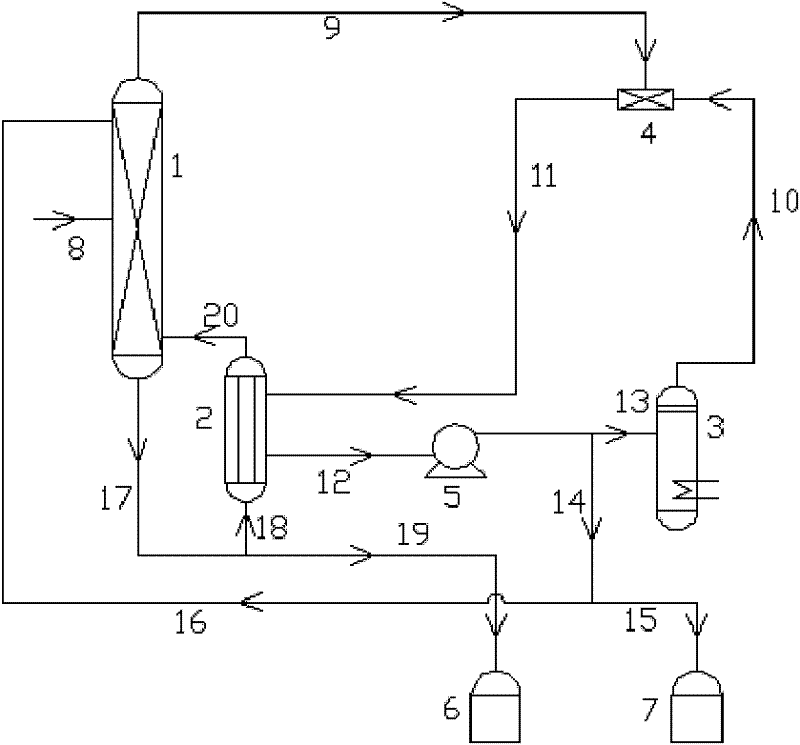

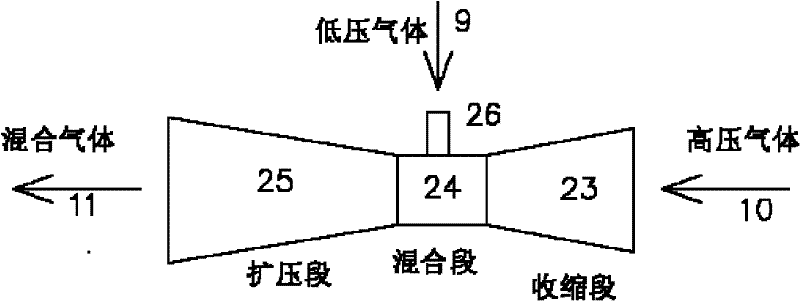

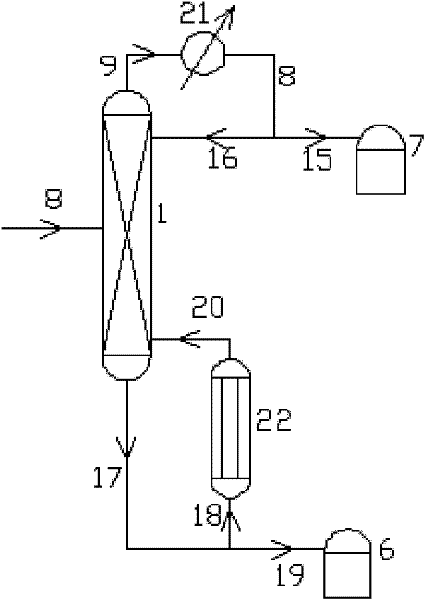

[0023] Such as figure 1 , figure 2 Shown, adopt the separation device of the heat pump rectification purification trichlorosilane of static mixing booster, comprise rectification tower, condensation reboiler and evaporator, it is characterized in that in rectification tower, condensation reboiler and evaporator A static mixing booster is arranged between them; the static mixing booster is composed of a constriction section, a mixing section, a lateral injection pipe and a diffuser section from the inlet to the outlet; The lateral injection pipe of the device is connected, the constriction section of the static mixing booster is connected with the evaporator, and the condensing reboiler is connected with the diffuser section of the static mixing booster.

[0024] A trichlorosilane heat pump energy-saving rectification met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com