Preparation method of Oxiracetam

A technique called ammonolysis reaction, applied in the direction of organic chemistry, etc., can solve the problems of affecting the quality of oxiracetam, high price of sodium azide, and explosiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

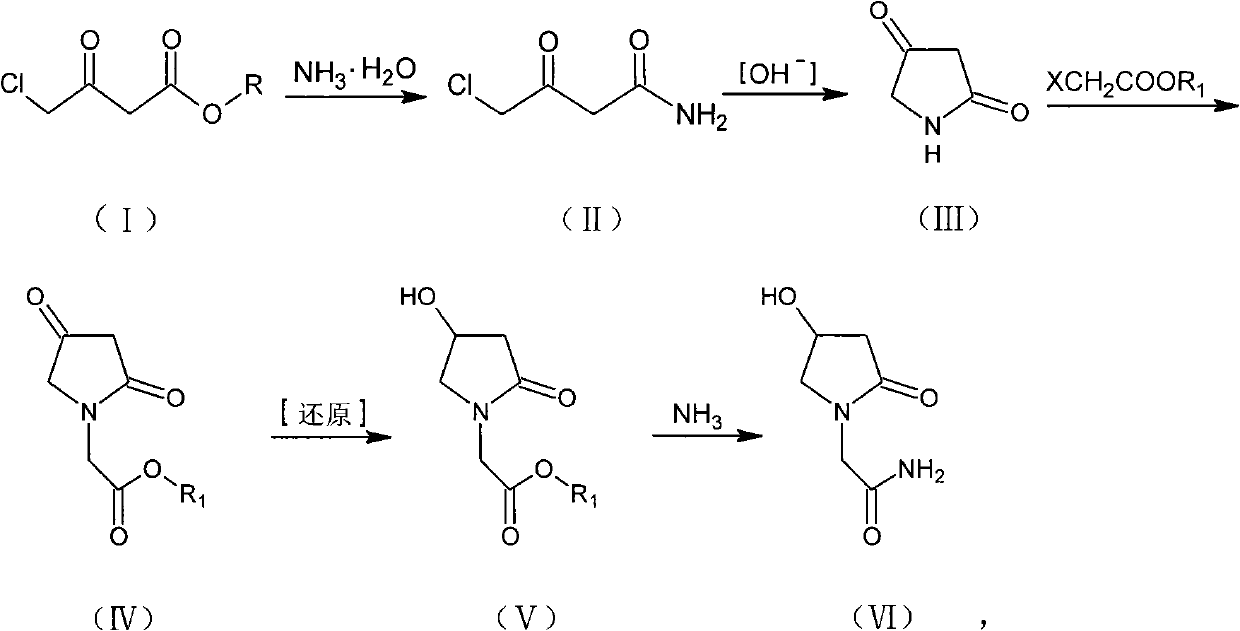

AI Technical Summary

Problems solved by technology

Method used

Image

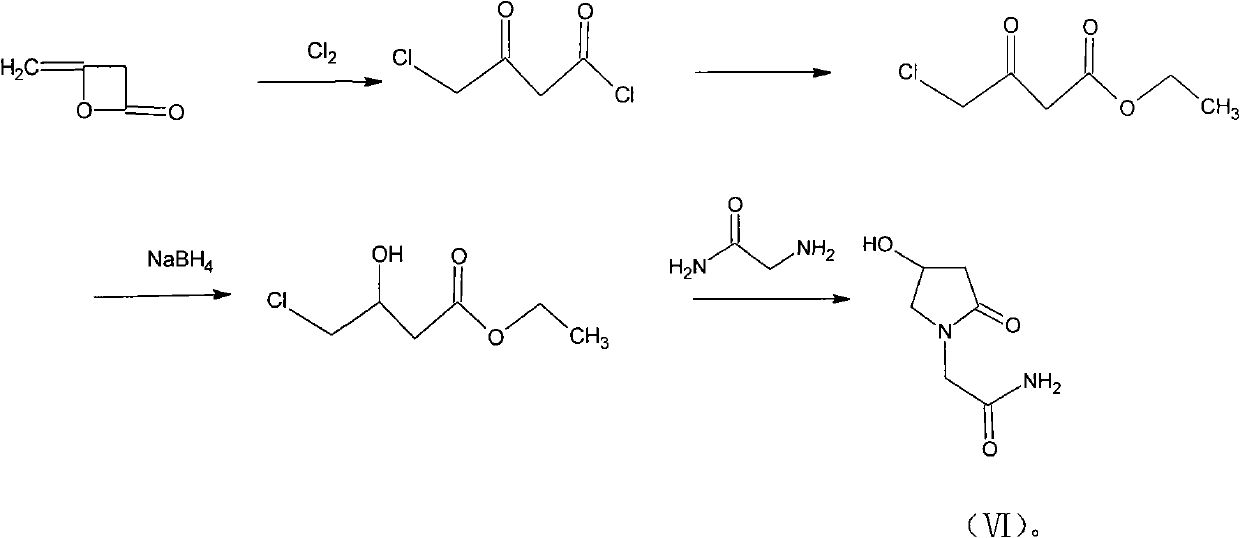

Examples

Embodiment 1

[0028] Embodiment 1: the preparation of 4-chloroacetoacetamide (II)

[0029] Method 1: Add methyl 4-chloroacetoacetate dropwise to 100L of concentrated ammonia water with a concentration of 25-28w% cooled to 0-5°C

[0030] (I) 20kg, continue to stir and react for 2 hours after dropping, filter, wash the filter cake with cold water lower than 10°C, and dry to obtain 13.6kg of 4-chloroacetoacetamide (II), with a yield of 75.6%.

[0031] Method 2: Add dropwise ethyl 4-chloroacetoacetate to 100L of concentrated ammonia water with a concentration of 25-28w% cooled to 0-5°C

[0032] (I) 20kg, continue to stir and react for 2 hours after dropping, filter, wash the filter cake with cold water below 10°C, and dry to obtain 11.9kg of 4-chloroacetoacetamide (II), with a yield of 72.1%.

Embodiment 2

[0033] Embodiment 2: the preparation of pyrrolidine-2,4-dione (III)

[0034] Method 1: Mix 13kg of 4-chloroacetoacetamide (II) with 104L of methanol and 19.9kg of potassium carbonate, pH9-10, and heat up and reflux for 12 hours. Filtrate while hot, and cool the filtrate to 0-5°C for crystallization for 4 hours. Filter, wash with methanol, and dry to obtain 5.9 kg of pyrrolidine-2,4-dione (III), with a yield of 62.1% and a melting point of 120-122°C.

[0035] Method 2: Mix 13kg of 4-chloroacetoacetamide (II) with 104L of ethanol and 19.9kg of potassium carbonate, pH9-10, heat up and reflux for 8 hours and filter while hot, and cool the filtrate to 0-5°C for crystallization for 4 hours. Filter, wash with ethanol, and dry to obtain 6.1 kg of pyrrolidine-2,4-dione (III), with a yield of 64.2% and a melting point of 120.5-122°C.

[0036]Method 3: Mix 13kg of 4-chloroacetoacetamide (II) with 130L of acetone and 19.9kg of potassium carbonate, pH 9-10, heat up and reflux for 12 hour...

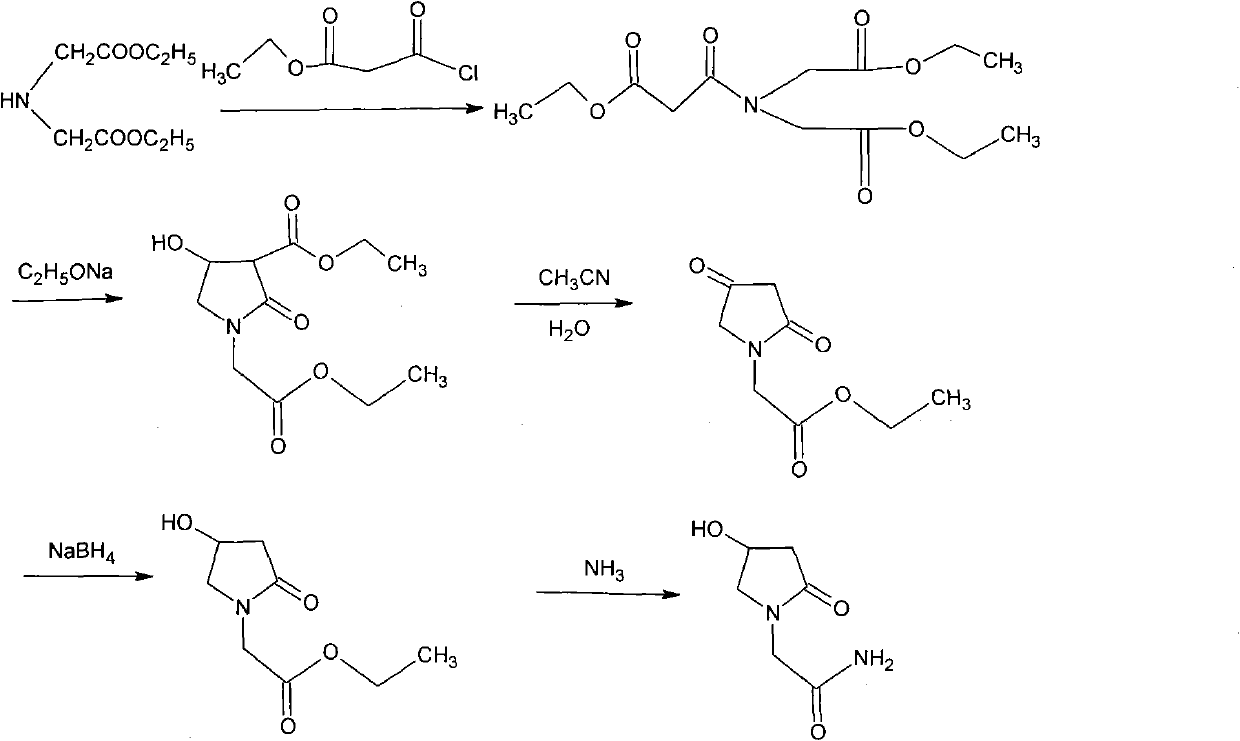

Embodiment 3

[0041] Example 3: Preparation of 2-(2,4-dioxopyrrolidin-1-yl) acetate (IV)

[0042] Method 1: Suspend 60% 2.5kg of sodium hydride in 60L of toluene, slowly add 6kg of pyrrolidine-2,4-dione (III), stir and react at room temperature for 1 hour, then add 8.2kg of ethyl chloroacetate dropwise at room temperature, drop After heating up to 50-60°C for 8 hours, cool to room temperature, add 20 L of water to wash the toluene layer, repeat once, separate the toluene layer, dry, filter, and concentrate to obtain 2-(2,4-dioxopyrrolidine- 1-yl) ethyl acetate (IV) 8.9kg, yield 79.5%, melting point 88-91°C.

[0043] Method 2: Suspend 60% 2.5 kg of sodium hydride in 60 L of toluene, slowly add 6 kg of pyrrolidine-2,4-dione (III), stir and react at room temperature for 1 hour, then add 7.2 kg of methyl chloroacetate dropwise at room temperature, drop After heating up to 50-60°C for 8 hours, cool to room temperature, add 20 L of water to wash the toluene layer, repeat once, separate the tolue...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com