Method for improving hydrogen production by photosynthetic bacteria using bubbling process

A technology of photosynthetic bacteria and bubbling, which is applied in the field of using bubbling to improve the hydrogen production of photosynthetic bacteria, which can solve the problems of complex reactor design, low hydrogen production rate, large distance between industrial production and practical application, etc., so as to facilitate metabolism Effects of growth, increasing cell concentration, and reducing product inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] In this embodiment, Rhodopseudomonas palustris is used as the object of implementation, and Rhodopseudomonas palustris belongs to purple non-sulfur photosynthetic bacteria.

[0020] Inoculate the photosynthetic bacteria suspension cultured to the logarithmic growth phase into the sterilized medium, put it into the bubbling photobiochemical reactor, cultivate hydrogen production in batches, and collect the gas by drainage method, every 3h The reactor was subjected to Ar bubbling once at a gas flow rate of 0.2 L / min for 5 min each time.

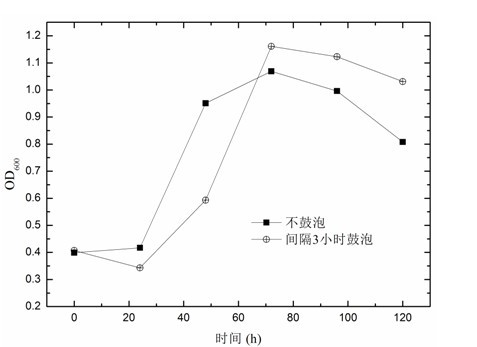

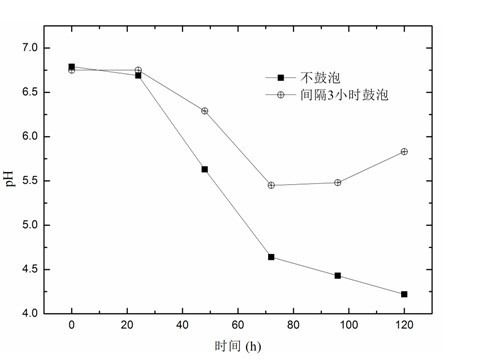

[0021] Such as Figure 1(a) with Figure 1(b) As shown, under the same culture conditions, bubbling has a great influence on the growth and metabolism of photosynthetic bacteria: the average cell concentration of photosynthetic bacteria is higher under the condition of blowing Ar to the reactor at intervals of 3 hours; the pH value decreases after the middle stage of the reaction rising trend.

Embodiment 2

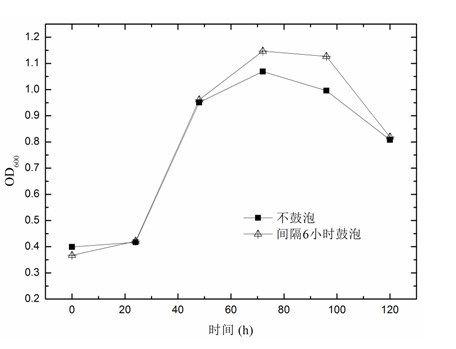

[0023] The reactor was bubbled with Ar every 6 h at a gas flow rate of 0.2 L / min for 5 min each time. The concentration of photosynthetic bacteria and the pH value of the medium change as Figure 3(a) with Figure 3(b) shown.

Embodiment 3

[0025] The reactor was bubbled with Ar every 12 h at a gas flow rate of 0.2 L / min for 5 min each time. The concentration of photosynthetic bacteria and the pH value of the medium change as Figure 3(a) with Figure 3(b) shown.

[0026] Figure 4 It is a comparison chart of the total hydrogen production of photosynthetic bacteria under four conditions. It can be seen from the figure that the hydrogen production of photosynthetic bacteria under bubbling conditions is significantly higher than that under no bubbling conditions, and the bubbling conditions are separated by 3 hours The hydrogen production was the highest, reaching 33 mmol. Figure 5 It is a comparison chart of light energy conversion efficiency and hydrogen production rate of photosynthetic bacteria under four conditions. It can be seen from the figure that the light energy conversion efficiency and hydrogen production rate of photosynthetic bacteria under the condition of bubbling at intervals of 3 hours are m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com