A bionic fluidized carrier for wastewater treatment biological fluidized bed and its preparation method and application

A biological fluidized bed, wastewater treatment technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of poor hydrophilicity and biological affinity, anaerobic fluidized bed Problems such as difficulty in start-up and small amount of microorganisms loaded on the carrier can shorten the film hanging time, improve rigidity and high biological affinity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

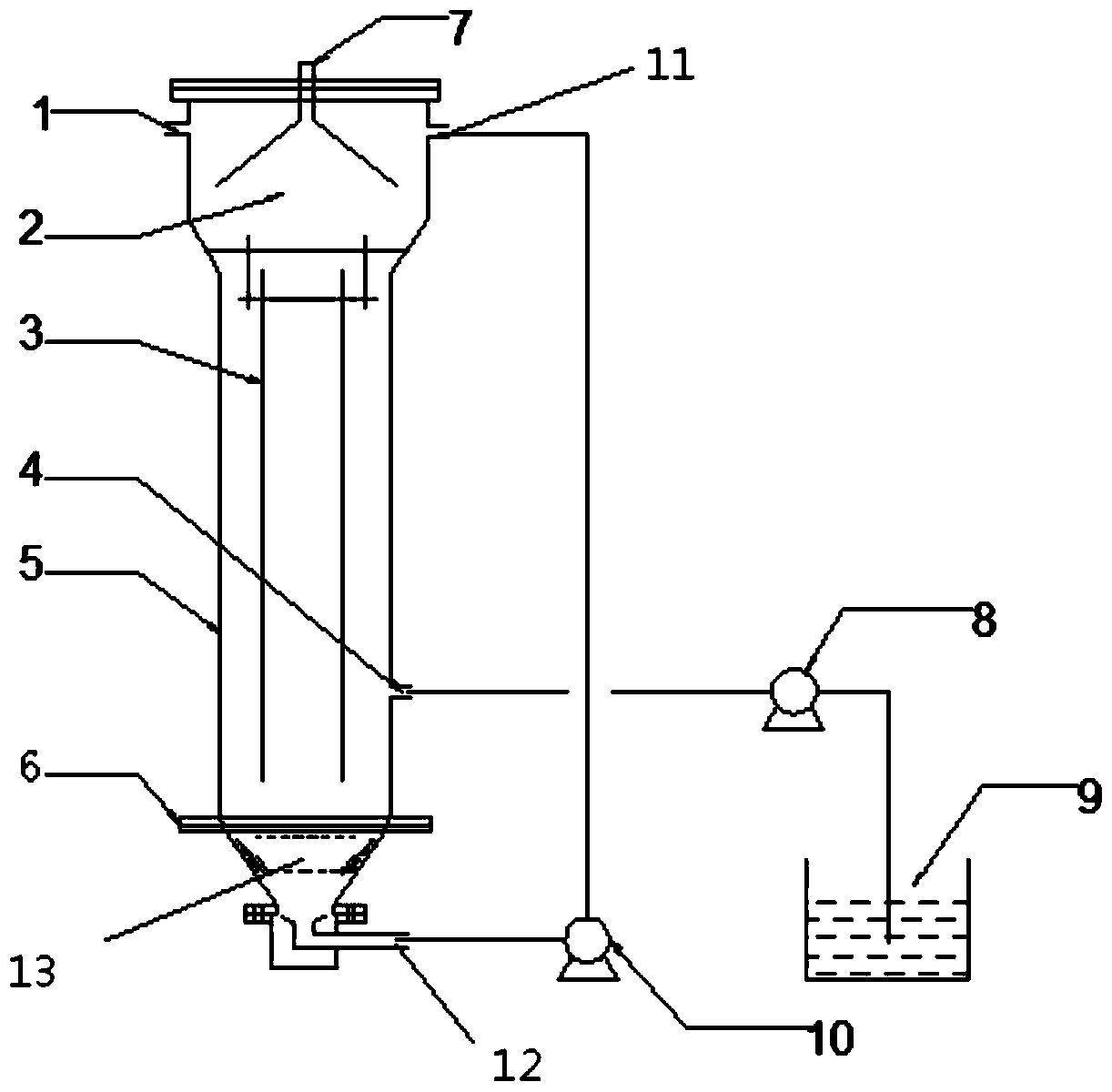

[0024] Such as figure 1 Shown is a schematic structural view of a biological fluidized bed according to the present invention, which includes a three-phase separator 2, an inner cylinder 3, an outer cylinder 5, a water distributor 13 and a raw water tank 9; wherein the three-phase The separator 2 is arranged above the outer cylinder 5, the inner cylinder 3 is arranged inside the outer cylinder 5, the water distributor 13 is arranged under the outer cylinder 5, and is connected with the outer cylinder 5 through the flange 6; the three-phase separation The top of the device 2 is provided with a biogas outlet 7, and the upper part of the side wall of the three-phase separator 2 is respectively provided with a sample outlet 1 and a water outlet 11, wherein the height of the water outlet 11 is lower than that of the sample outlet 1; There is a sample inlet 4, which communicates with the raw water tank 9 through a sample pump 8; a water inlet 12 is provided below the water distribut...

Embodiment 2

[0027] A bionic fluidized carrier for a biological fluidized bed for wastewater treatment, which is composed of the following components according to the mass fraction ratio: high molecular polymer 85%, animal waste 11%, trace elements 3%, inorganic filler 1%; bionic carrier The added amount is 50% of the effective volume of the biological fluidized bed. Among them, the high molecular polymer is polypropylene, the animal waste is bone glue and bone meal, and the weight ratio of bone glue and bone meal is 1:1; trace elements are zinc sulfate, manganese chloride, ferrous sulfate, copper chloride, cobalt chloride, Nickel sulfate; the inorganic filler is calcium carbonate.

[0028] The preparation method is as follows:

[0029] (1) Raw materials are batched according to the mass fraction ratio, premixed and coarsely dispersed in a mixer, the stirring speed is 100 rpm, and the stirring time is 60 minutes;

[0030] (2) Add the premixed raw materials in step (1) into a ball mill fo...

Embodiment 3

[0037] A bionic fluidized carrier for a biological fluidized bed for wastewater treatment, which is composed of the following components according to the mass fraction ratio: high molecular polymer 90%, animal waste 6%, trace elements 3%, inorganic filler 1%; bionic carrier The added amount is 60% of the effective volume of the biological fluidized bed. Among them, the high molecular polymer is polyethylene, the animal waste is bone glue, the trace elements are zinc sulfate, manganese chloride, ferrous sulfate, copper chloride, cobalt chloride, nickel sulfate; the inorganic filler is wollastonite.

[0038] The preparation method is as follows:

[0039] (1) The raw materials are batched according to the mass fraction ratio, and they are premixed and coarsely dispersed in a mixer, the stirring speed is 120 rpm, and the stirring time is 45 minutes;

[0040] (2) adding the premixed raw materials in step (1) into a ball mill for fine dispersion, the ball mill rotating speed is 60 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com