A kind of sludge sludge water separation method

A sludge-water separation and sludge technology, applied in water/sludge/sewage treatment, sludge treatment, biological sludge treatment, etc., can solve the problems of environmental hazards, mud cake compaction, sludge drying and incineration costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] When sludge is processed by the present invention, in the humus-containing sludge of 1000ml moisture content 95%, add superfine fly ash 2.5g, soil modification material (phosphogypsum powder: zeolite powder: diatomaceous earth=20: 55:25) 2.5g, lignocellulose powder 2.5g, characteristic engineering microorganism (photosynthetic bacteria powder: yeast: Bacillus = 55:25:20) 0.05g, magnesium sulfate 0.5g, calcium chloride 2.5g, cationic polymerization MT 0.25g, 1‰ cationic polyacrylamide 0.5g, stirred for 3 minutes, squeezed by bag filter press under 0.8MPa pressure, weighed the mud cake, and measured the moisture content of the sludge to 60%. The porosity of the mud cake is 65%, the mud cake is loose and does not escape during press filtration, and does not smell bad when stacked and fermented.

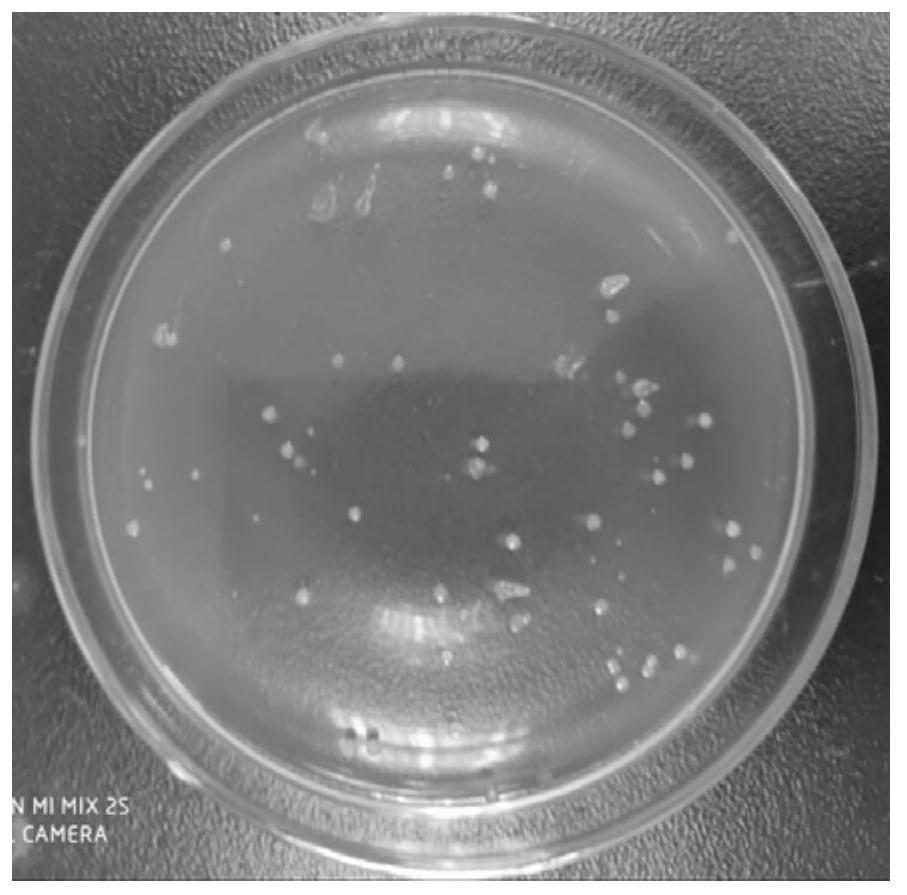

[0031] Soil dilution was used to spread plate method, and beef extract peptone solid medium was used to cultivate mud cake microorganisms, and the biological activity of mud cake ...

Embodiment 2

[0033] When sludge is processed by the present invention, add straw rice husk ash 5.0g, soil modification material (phosphogypsum powder: zeolite powder: diatomaceous earth=20:50: 30) 2.5g, straw powder 2.5g, characteristic engineering microorganism (photosynthetic bacteria powder: yeast: bacillus = 50:20:30) 0.10g, magnesium sulfate 1.0g, calcium sulfate 2.5g, cationic polymer MT 0.50g, 1‰ cationic polyacrylamide 0.5g, stirred for 3 minutes, squeezed under the pressure of 0.8MPa by bag filter, weighed the mud cake, and measured the moisture content of the sludge to be 59%. The porosity of the mud cake is 65%, the mud cake is loose and does not escape during press filtration, and does not smell bad when stacked and fermented.

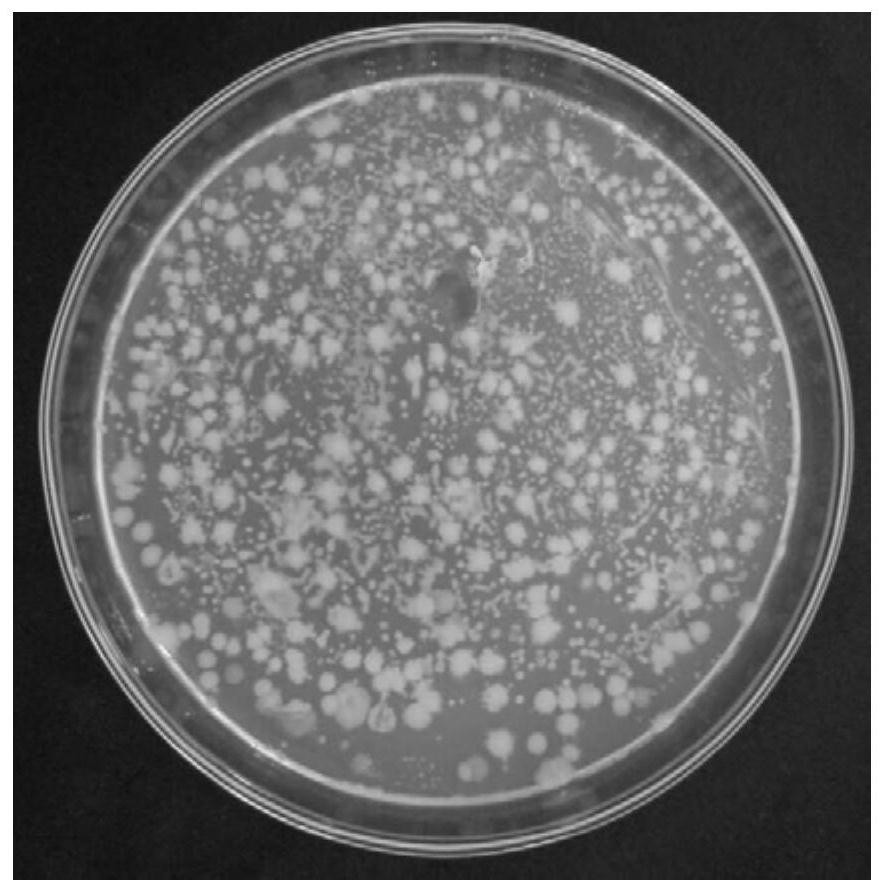

[0034] Cultivate the mud cake microorganism in the same way as in Example 1, and cultivate the 3rd day bacterial colony state such as image 3 . Compared figure 1 and 3 In the number of colonies, it can be seen that the number of colonies of the mud...

Embodiment 3

[0036] When sludge is processed by the present invention, add superfine fly ash 2.5g, soil modification material (phosphogypsum powder: zeolite powder: diatomaceous earth=20:60: 20) 2.5g, sepiolite powder 0.5g, characteristic engineering microorganism (photosynthetic bacteria powder: yeast: bacillus = 60:30:10) 0.1g, magnesium oxide 0.5g, calcium chloride 2.5g, cationic polymer MT 0.5 g. 0.5 g of 1‰ cationic polyacrylamide, stirred for 3 minutes, squeezed under a pressure of 0.8 MPa by bag filter, weighed the mud cake, and measured the moisture content of the sludge to be 57%. The porosity of the mud cake is 50%, the mud cake is loose and does not escape during press filtration, and does not smell bad when stacked and fermented.

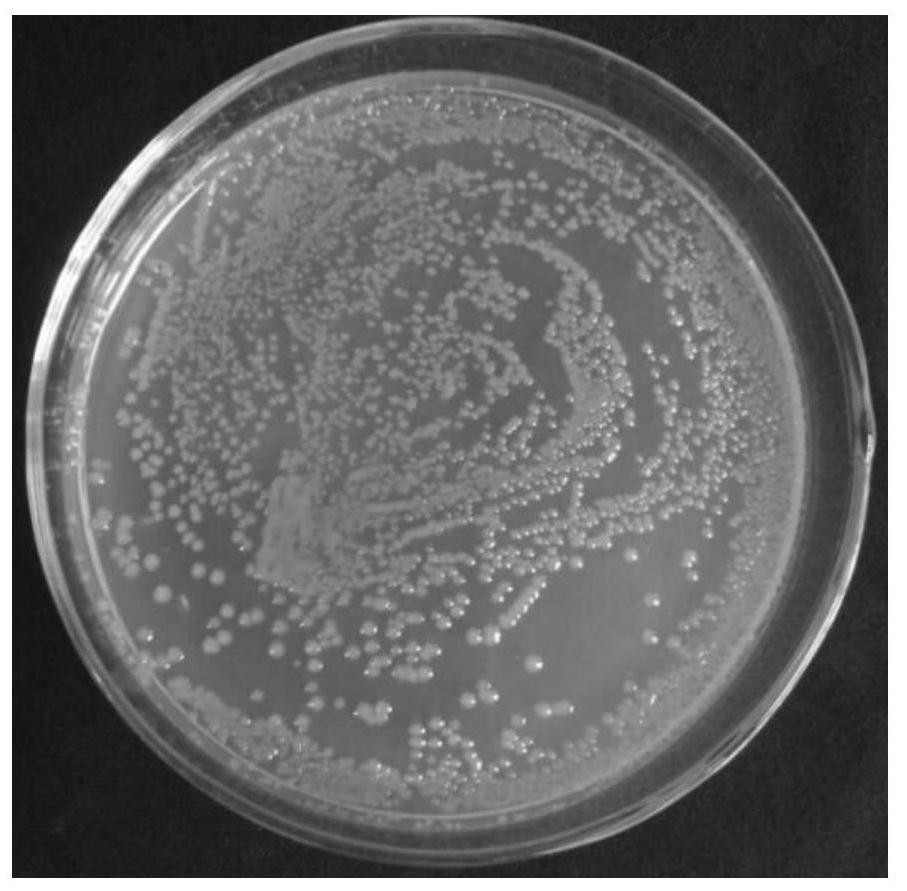

[0037] Cultivate the mud cake microorganism in the same way as in Example 1, and cultivate the 3rd day bacterial colony state such as Figure 4 . Compared figure 1 and 4 In the number of colonies, it can be seen that the number of colonies of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com